Forcompleteserviceinformationalsosee:

ComponentTechnicalManuals3029

Engine

AlternatorsandStartingMotors

Forcompleteserviceinformationalsosee:

ComponentTechnicalManuals3029

Engine

AlternatorsandStartingMotors

Thismanualiswrittenforanexperiencedtechnician. Essentialtoolsrequiredinperformingcertainservice workareidentifiedinthismanualandare recommendedforuse.

Livewithsafety:Readthesafetymessagesinthe introductionofthismanualandthecautionspresented throughoutthetextofthemanual.

Thisisthesafety-alertsymbol.Whenyouseethis symbolonthemachineorinthismanual,bealertto thepotentialforpersonalinjury.

Technicalmanualsaredividedintwoparts:repairand operationandtests.Repairsectionstellhowtorepair thecomponents.Operationandtestssectionshelpyou identifythemajorityofroutinefailuresquickly.

Informationisorganizedingroupsforthevarious componentsrequiringserviceinstruction.Atthe beginningofeachgrouparesummarylistingsofall applicableessentialtools,serviceequipmentandtools, othermaterialsneededtodothejob,servicepartskits, specifications,weartolerances,andtorquevalues.

TechnicalManualsareconciseguidesforspecific machines.Theyareon-the-jobguidescontainingonly thevitalinformationneededfordiagnosis,analysis, testing,andrepair.

Fundamentalserviceinformationisavailablefrom othersourcescoveringbasictheoryofoperation, fundamentalsoftroubleshooting,generalmaintenance, andbasictypeoffailuresandtheircauses.

DX,TMIFC–19–29SEP98–1/1

SECTION10—GeneralInformationSECTION90—OperatorStationRepair Group05—SeatandSupport Group05—Safety Group10—GeneralSpecificationsGroup10—ROLL-GARD Group15—OperatorPlatform Group20—FuelandLubricants Group25—SerialNumberLocationsGroup20—Fenders 20 Group30—FeaturesandAccessories

SECTION20—EngineRepair Group05—Engine Group10—CoolingSystem

SECTION210—OperationalCheckoutProcedures Group10—OperationalCheckoutProcedures

SECTION220—EngineOperation,Testsand Adjustments Group05—ComponentLocation

SECTION30—FuelandAirRepair Group05—FuelSystemGroup10—TheoryofOperation Group15—Diagnosis,TestsandAdjustments Group10—AirIntakeSystem Group15—SpeedControlLinkage

SECTION230—Fuel/AirOperation,Testsand Adjustments

SECTION40—ElectricalRepair Group05—Battery,StarterandAlternatorGroup05—ComponentLocation Group10—TheoryofOperation Group10—ElectricalSystemComponents Group15—WiringHarnessGroup15—Diagnosis,TestsandAdjustments

SECTION50—PowerTrainRepair Group05—ClutchHousing &Adjust Group05—ComponentLocation Group10—ClutchAssembly Group15—TransmissionGroup10—TheoryofOperation Group15—Diagnosis,TestandAdjust Group20—RearPTO

SECTION240—ElectricalSystemOperation,Tests

Group25—DifferentialGroup20—WiringSchematics Group30—FinalDrives Group35—MechanicalFrontWheelDrive

SECTION250—PowerTrainOperation,Tests& Adjustments Group05—ComponentLocation—PowerTrain

SECTION60—SteeringandBrakeRepair Group05—SteeringRepairGroup10—TheoryofOperation—Transmission Group15—Diagnosis,TestsandAdjustments— Group10—BrakeRepair PowerTrain

SECTION70—HydraulicRepair Group05—HydraulicPumpandFilter

SECTION260—SteeringandBrakeOperation,Test &Adjust Group10—Rockshaft

Group15—SelectiveControlValve(SCV)Group05—ComponentLocation Group10—TheoryofOperation Group20—HydraulicMidMountCoupler Group15—Diagnosis,TestsandAdjustments

SECTION80—MiscellaneousRepair Group05—FrontAxle—2WD

SECTION270—HydraulicSystemOperation,Test& Group10—Wheels Group15—3-PointHitch

Allinformation,illustrationsandspecificationsinthismanualarebasedon thelatestinformationavailableatthetimeofpublication.Therightisreservedtomakechangesatanytimewithoutnotice.

Adjust Group05—ComponentLocation Group10—TheoryofOperation Group15—Diagnosis Group16—HydraulicTests—WithoutSCV 20 Group17—HydraulicTests—WithSCV Group18—HydraulicTests—WithMidMount ControlValve Group19—HydraulicTests—All Group20—Adjustments Group21—HydraulicSchematics

Group05—Safety ......................10-05-1

Group10—GeneralSpecifications

GroundSpeedEstimates ................. 10-10-9

ServiceRecommendationsforO-RingBoss Fittings ............................ 10-10-15

ServiceRecommendationsforFlatFace O-RingSealFittings 10-10-17

MetricBoltandCapScrewTorqueValues...10-10-18

UnifiedInchBoltandCapScrewTorque Values 10-10-19

Group20—FuelandLubricants

Group25—SerialNumberLocations SerialNumbers ......................... 10-25-1

ProductIdentificationNumberLocation 10-25-1

EngineSerialNumberLocation 10-25-1

FuelInjectionPumpSerialNumberLocation...10-25-1

AlternatorSerialNumberLocation 10-25-2

PowerSteeringValveSerialNumber Location 10-25-2

StarterSerialNumberLocation 10-25-2

TransmissionSerialNumberLocation ........ 10-25-2

FrontAxle(2WD)SerialNumberLocation .....10-25-3

MechanicalFrontWheelDrive(MFWD)Serial NumberLocation 10-25-3

Group30—FeaturesandAccessories FeaturesandAccessories ................. 10-30-1

Thisisasafety-alertsymbol.Whenyouseethissymbol onyourmachineorinthismanual,bealerttothe potentialforpersonalinjury.

Followrecommendedprecautionsandsafeoperating practices.

Asignalword—DANGER,WARNING,orCAUTION—is usedwiththesafety-alertsymbol.DANGERidentifiesthe mostserioushazards.

DANGERorWARNINGsafetysignsarelocatednear specifichazards.Generalprecautionsarelistedon CAUTIONsafetysigns.CAUTIONalsocallsattentionto safetymessagesinthismanual.

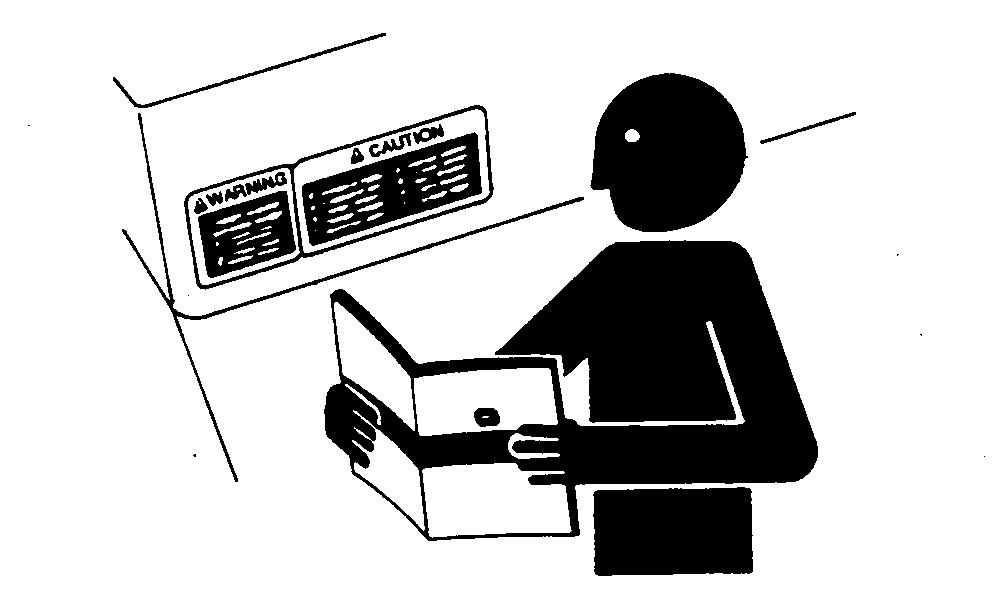

Carefullyreadallsafetymessagesinthismanualandon yourmachinesafetysigns.Keepsafetysignsingood condition.Replacemissingordamagedsafetysigns.Be surenewequipmentcomponentsandrepairpartsinclude thecurrentsafetysigns.Replacementsafetysignsare availablefromyourJohnDeeredealer.

Learnhowtooperatethemachineandhowtouse controlsproperly.Donotletanyoneoperatewithout instruction.

Keepyourmachineinproperworkingcondition. Unauthorizedmodificationstothemachinemayimpairthe functionand/orsafetyandaffectmachinelife.

Ifyoudonotunderstandanypartofthismanualandneed assistance,contactyourJohnDeeredealer.

Whenyouworkaroundfuel,donotsmokeorworknear heatersorotherfirehazards.

Storeflammablefluidsawayfromfirehazards.Donot incinerateorpuncturepressurizedcontainers.

Makesuremachineiscleanoftrash,grease,anddebris.

Donotstoreoilyrags;theycanigniteandburn spontaneously.

Keepsparks,lightedmatches,andopenflameawayfrom thetopofbattery.Batterygascanexplode.

Nevercheckbatterychargebyplacingametalobject acrosstheposts.Useavolt-meterorhydrometer.

Donotchargeafrozenbattery;itmayexplode.Warm batteryto16°C(60°F).

Bepreparedifafirestarts.

Keepafirstaidkitandfireextinguisherhandy.

Keepemergencynumbersfordoctors,ambulanceservice, hospital,andfiredepartmentnearyourtelephone.

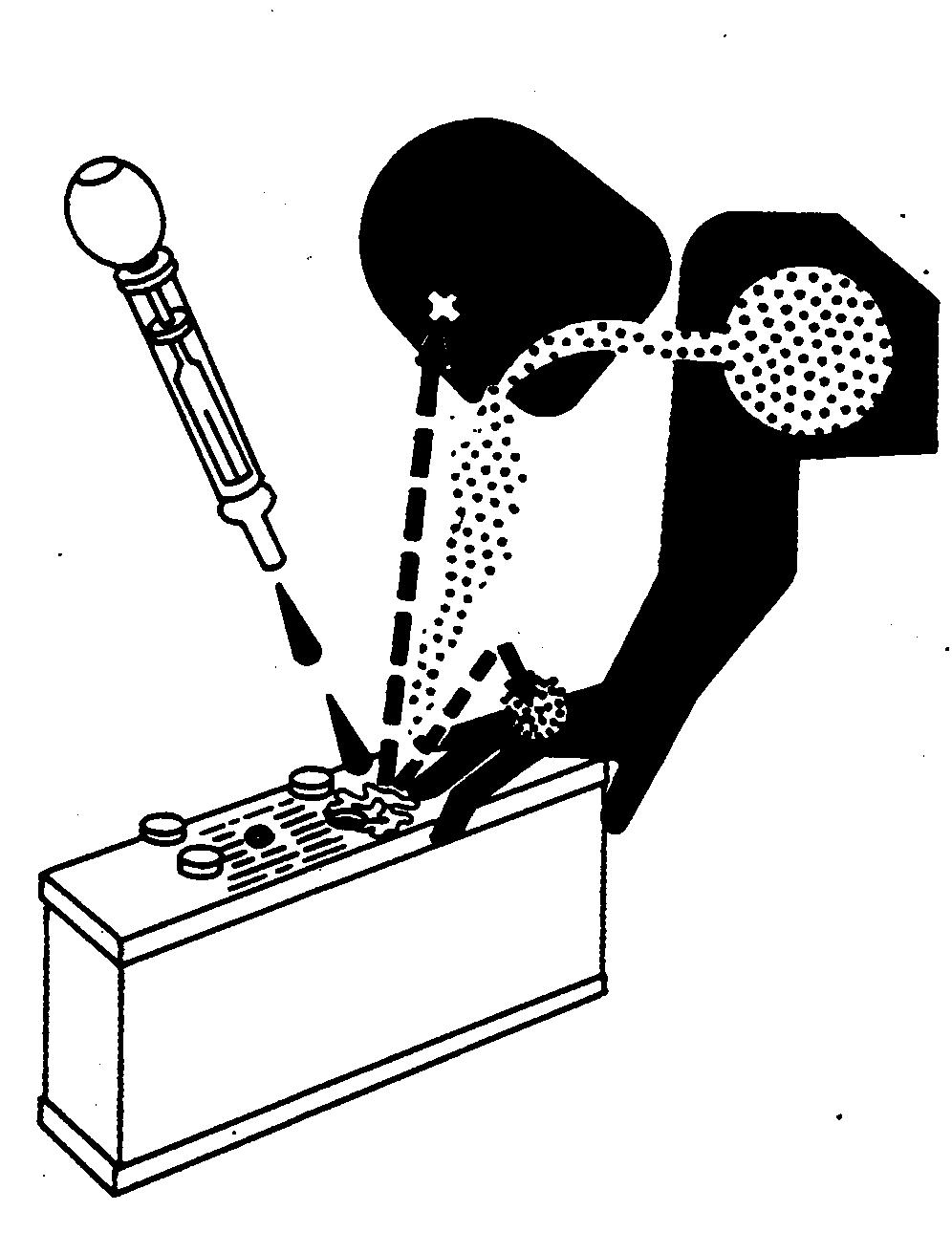

Sulfuricacidinbatteryelectrolyteispoisonous.Itisstrong enoughtoburnskin,eatholesinclothing,andcause blindnessifsplashedintoeyes.

Avoidthehazardby:

1.Fillingbatteriesinawell-ventilatedarea.

2.Wearingeyeprotectionandrubbergloves.

3.Avoidingbreathingfumeswhenelectrolyteisadded.

4.Avoidingspillingordrippingelectrolyte.

5.Useproperjumpstartprocedure.

Ifyouspillacidonyourself:

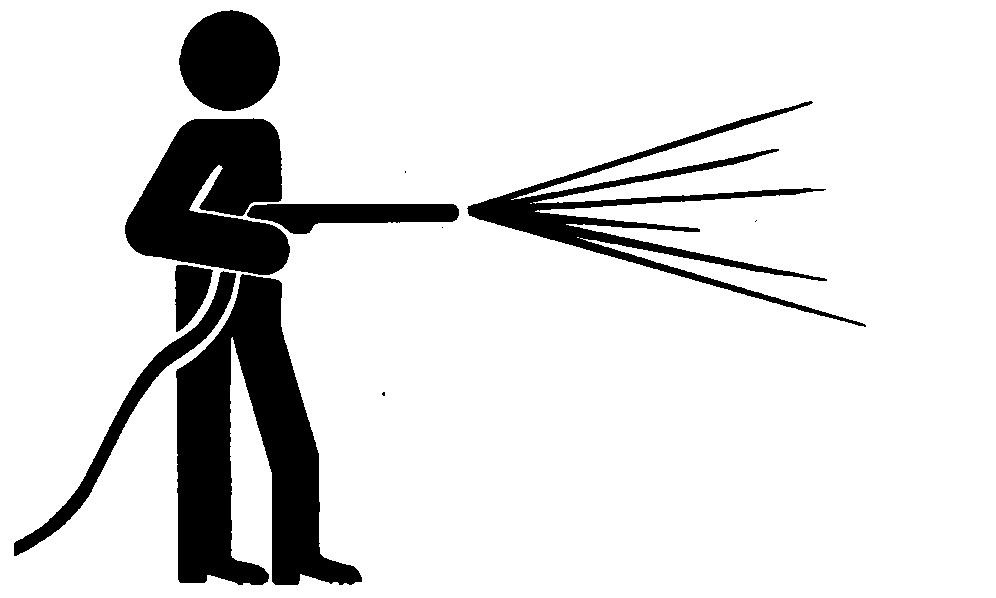

1.Flushyourskinwithwater.

2.Applybakingsodaorlimetohelpneutralizetheacid.

3.Flushyoureyeswithwaterfor15—30minutes.Get medicalattentionimmediately.

Ifacidisswallowed:

1.Donotinducevomiting.

2.Drinklargeamountsofwaterormilk,butdonot exceed2L(2 quarts).

3.Getmedicalattentionimmediately.

DX,POISON–19–21APR93–1/1

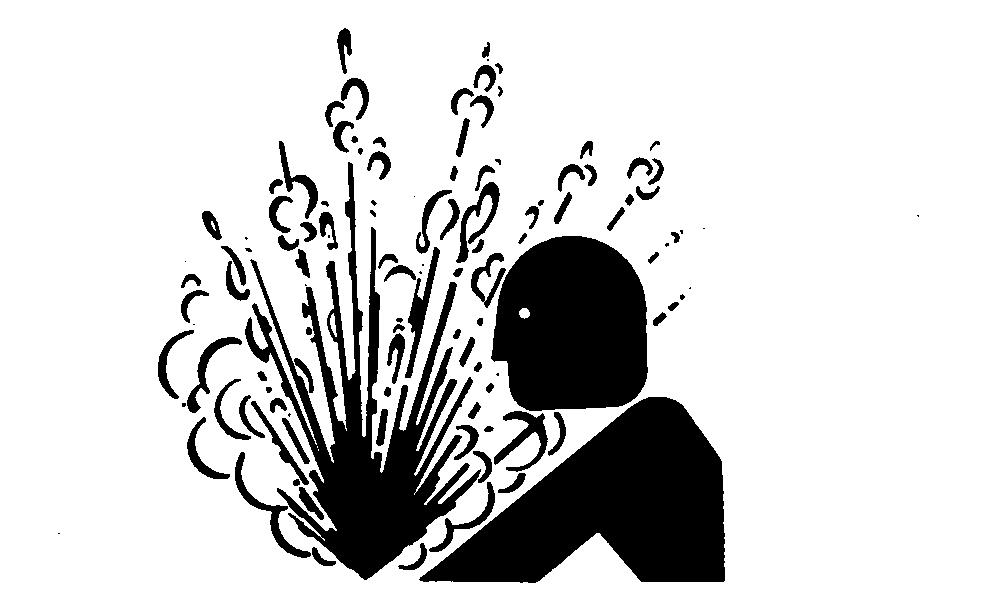

Explosivereleaseoffluidsfrompressurizedcooling systemcancauseseriousburns.

Shutoffengine.Onlyremovefillercapwhencoolenough totouchwithbarehands.Slowlyloosencaptofirststop torelievepressurebeforeremovingcompletely.

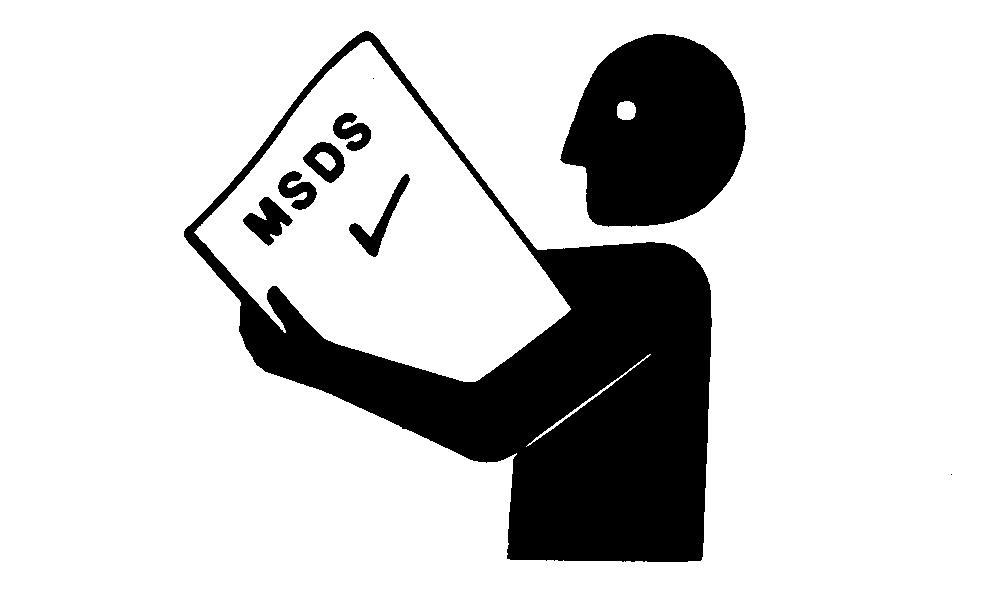

Directexposuretohazardouschemicalscancause seriousinjury.Potentiallyhazardouschemicalsusedwith JohnDeereequipmentincludesuchitemsaslubricants, coolants,paints,andadhesives.

AMaterialSafetyDataSheet(MSDS)providesspecific detailsonchemicalproducts:physicalandhealthhazards, safetyprocedures,andemergencyresponsetechniques.

ChecktheMSDSbeforeyoustartanyjobusinga hazardouschemical.Thatwayyouwillknowexactlywhat therisksareandhowtodothejobsafely.Thenfollow proceduresandrecommendedequipment.

(SeeyourJohnDeeredealerforMSDS’sonchemical productsusedwithJohnDeereequipment.)

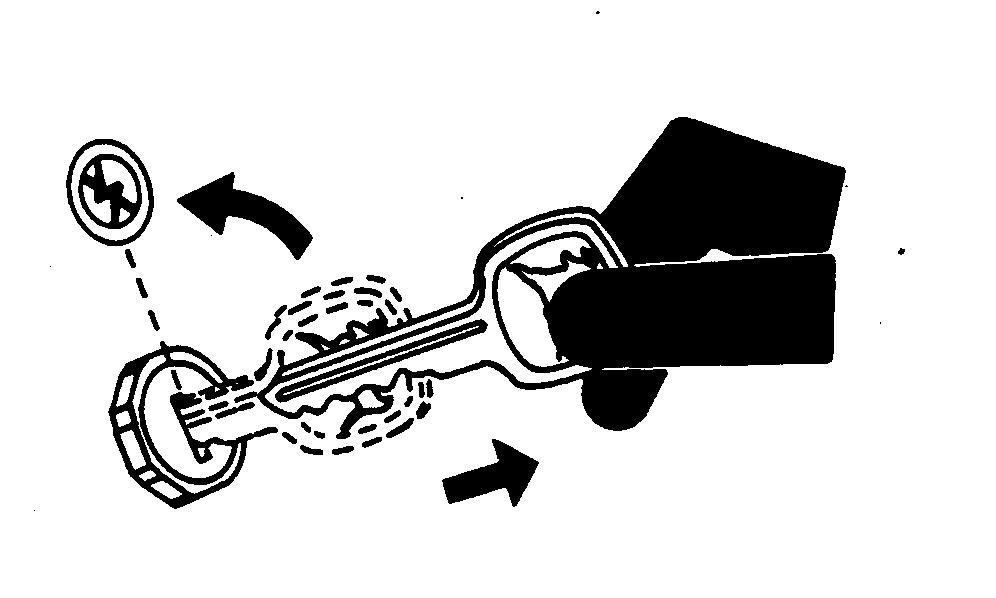

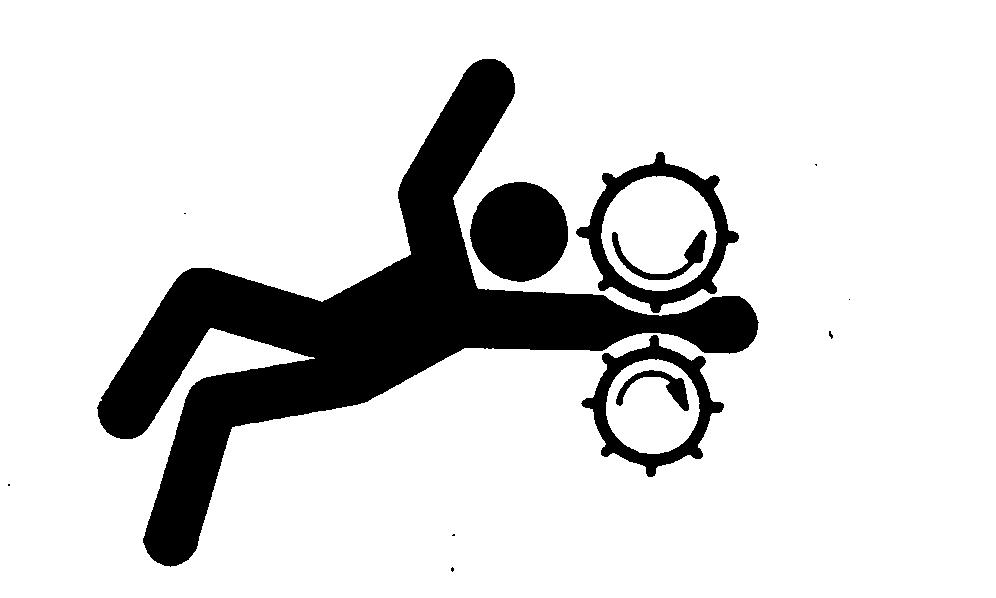

Escapingfluidunderpressurecanpenetratetheskin causingseriousinjury.

Avoidthehazardbyrelievingpressurebefore disconnectinghydraulicorotherlines.Tightenall connectionsbeforeapplyingpressure.

Searchforleakswithapieceofcardboard.Protecthands andbodyfromhighpressurefluids.

Ifanaccidentoccurs,seeadoctorimmediately.Anyfluid injectedintotheskinmustbesurgicallyremovedwithina fewhoursorgangrenemayresult.Doctorsunfamiliarwith thistypeofinjuryshouldreferenceaknowledgeable medicalsource.SuchinformationisavailablefromDeere &CompanyMedicalDepartmentinMoline,Illinois,U.S.A.

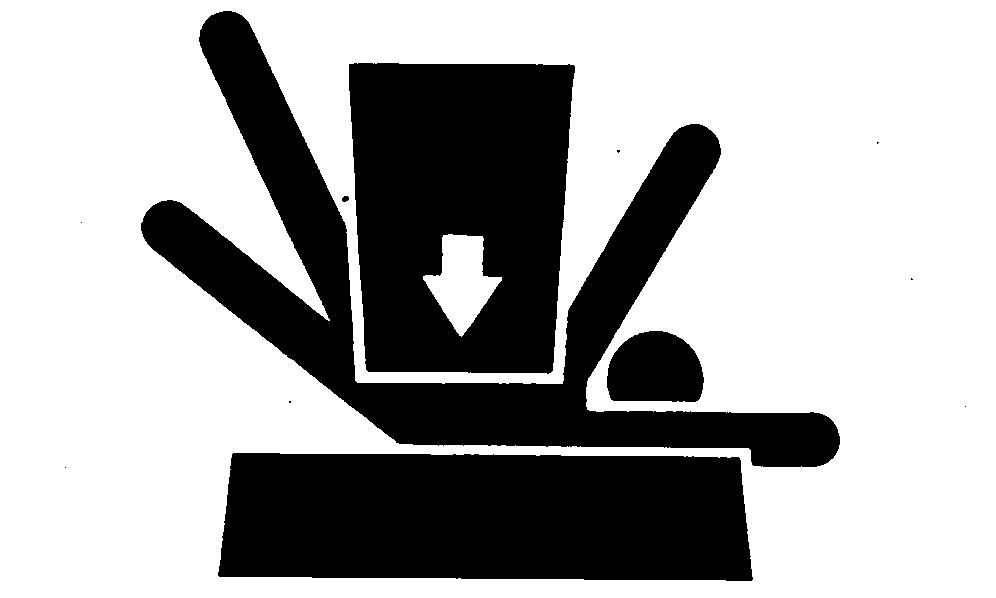

Beforeworkingonthemachine:

• Lowerallequipmenttotheground.

• Stoptheengineandremovethekey.

• Disconnectthebatterygroundstrap.

Alwayslowertheattachmentorimplementtotheground beforeyouworkonthemachine.Ifyoumustworkona liftedmachineorattachment,securelysupportthe machineorattachment.Ifleftinaraisedposition, hydraulicallysupporteddevicescansettleorleakdown.

Donotsupportthemachineoncinderblocks,hollowtiles, orpropsthatmaycrumbleundercontinuousload.Donot workunderamachinethatissupportedsolelybyajack. Followrecommendedproceduresinthismanual.

Whenimplementsorattachmentsareusedwithatractor, alwaysfollowsafetyprecautionslistedintheimplement operator’smanual.

• Hanga"DONOTOPERATE"taginoperatorstation. DX,LOWER–19–17FEB99–1/1

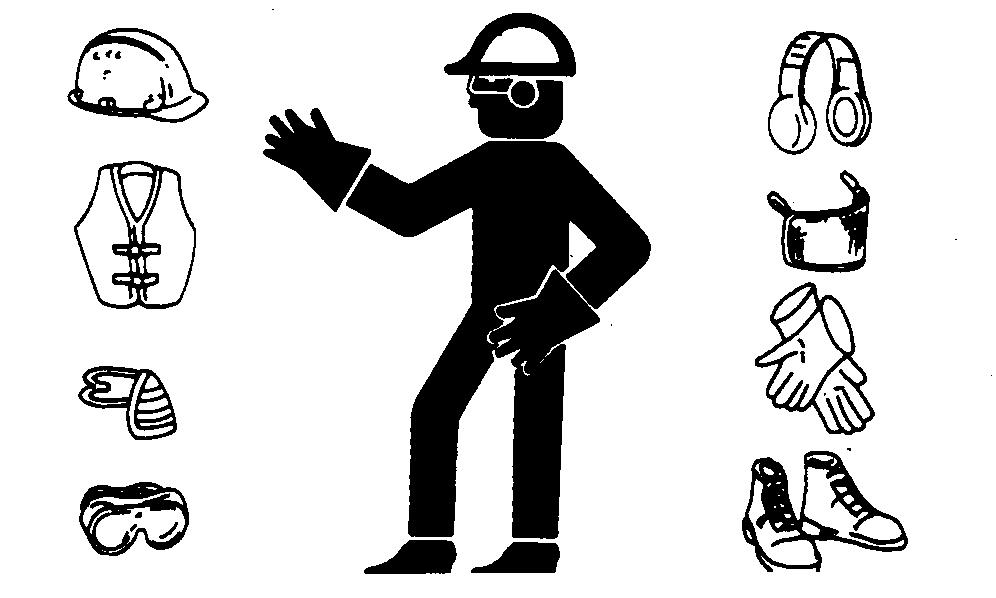

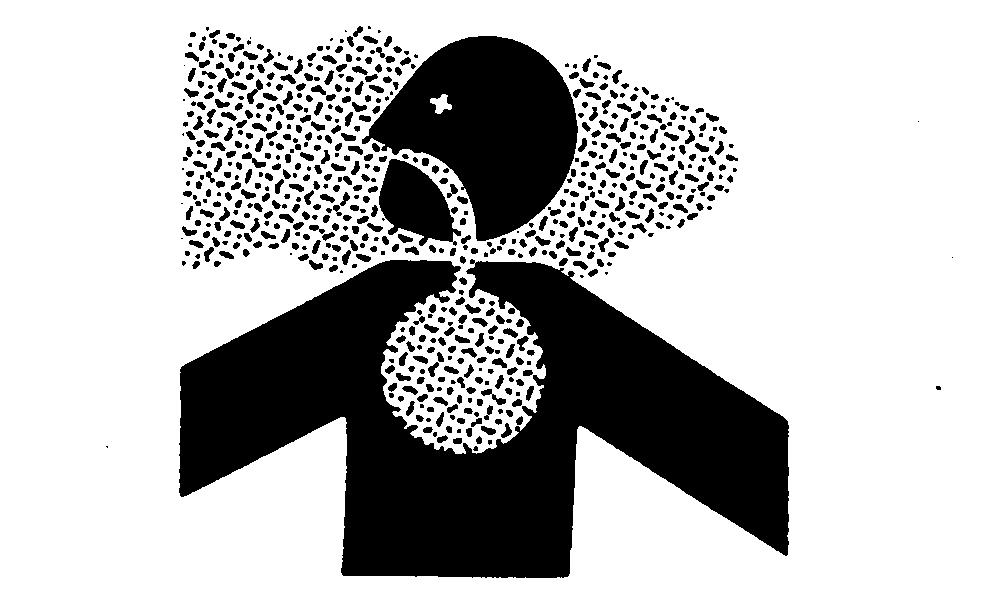

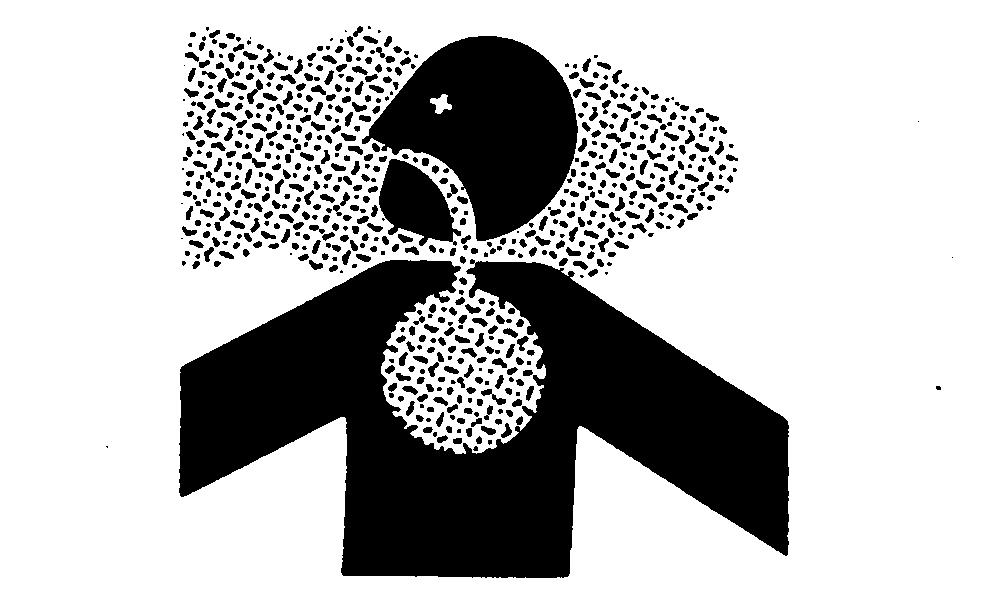

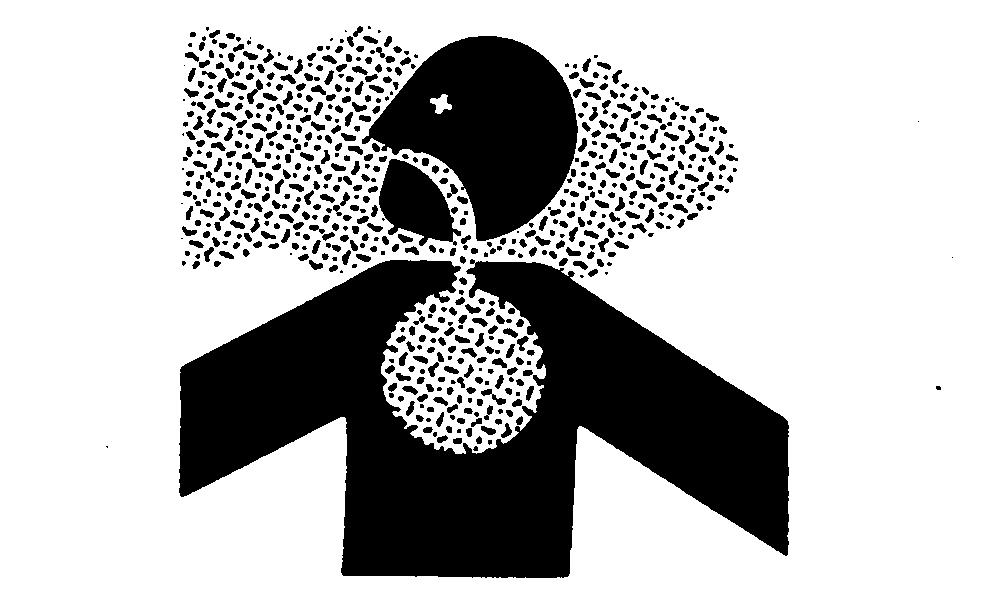

Wearclosefittingclothingandsafetyequipment appropriatetothejob.

Prolongedexposuretoloudnoisecancauseimpairment orlossofhearing.

Wearasuitablehearingprotectivedevicesuchas earmuffsorearplugstoprotectagainstobjectionableor uncomfortableloudnoises.

Operatingequipmentsafelyrequiresthefullattentionof theoperator.Donotwearradioormusicheadphones whileoperatingmachine.

Beforestartingajob:

• Cleanworkareaandmachine.

• Makesureyouhaveallnecessarytoolstodoyourjob.

• Havetherightpartsonhand.

• Readallinstructionsthoroughly;donotattempt shortcuts.

Tielonghairbehindyourhead.Donotwearanecktie, scarf,looseclothing,ornecklacewhenyouworknear machinetoolsormovingparts.Iftheseitemsweretoget caught,severeinjurycouldresult.

Removeringsandotherjewelrytopreventelectrical shortsandentanglementinmovingparts.

Engineexhaustfumescancausesicknessordeath.Ifitis necessarytorunanengineinanenclosedarea,remove theexhaustfumesfromtheareawithanexhaustpipe extension.

Ifyoudonothaveanexhaustpipeextension,openthe doorsandgetoutsideairintothearea

Illuminateyourworkareaadequatelybutsafely.Usea portablesafetylightforworkinginsideorunderthe machine.Makesurethebulbisenclosedbyawirecage. Thehotfilamentofanaccidentallybrokenbulbcanignite spilledfueloroil.

Replacemissingordamagedsafetysigns.Seethe machineoperator’smanualforcorrectsafetysign placement.

Liftingheavycomponentsincorrectlycancausesevere injuryormachinedamage.

Makecertainallpartsarereinstalledcorrectlyifthe roll-overprotectivestructure(ROPS)isloosenedor removedforanyreason.Tightenmountingboltstoproper torque.

TheprotectionofferedbyROPSwillbeimpairedifROPS issubjectedtostructuraldamage,isinvolvedinan overturnincident,orisinanywayalteredbywelding, bending,drilling,orcutting.AdamagedROPSshouldbe replaced,notreused.

Followrecommendedprocedureforremovaland installationofcomponentsinthemanual. DX,ROPS3–19–03MAR93–1/1

DX,LIFT–19–04JUN90–1/1

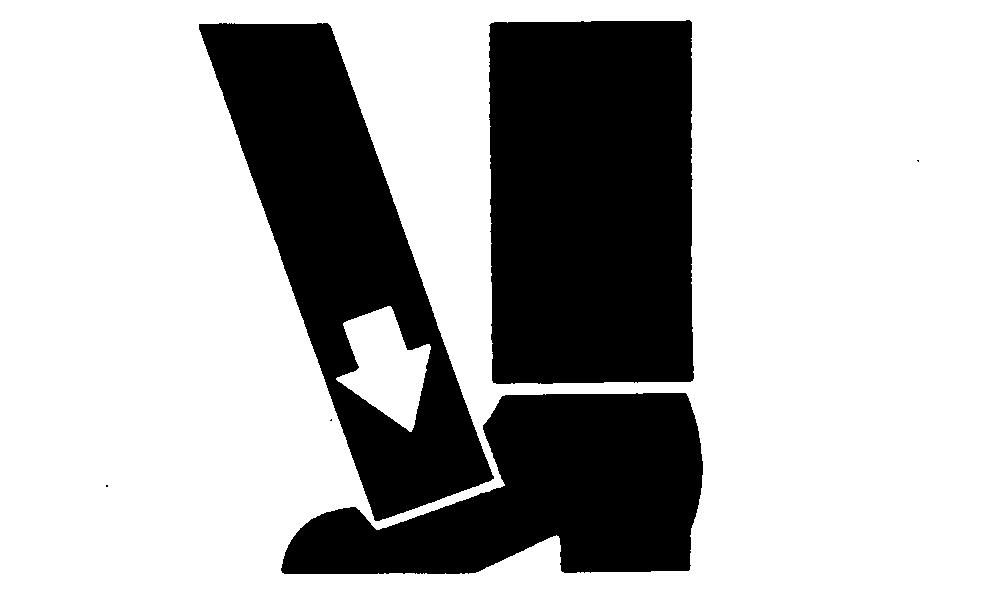

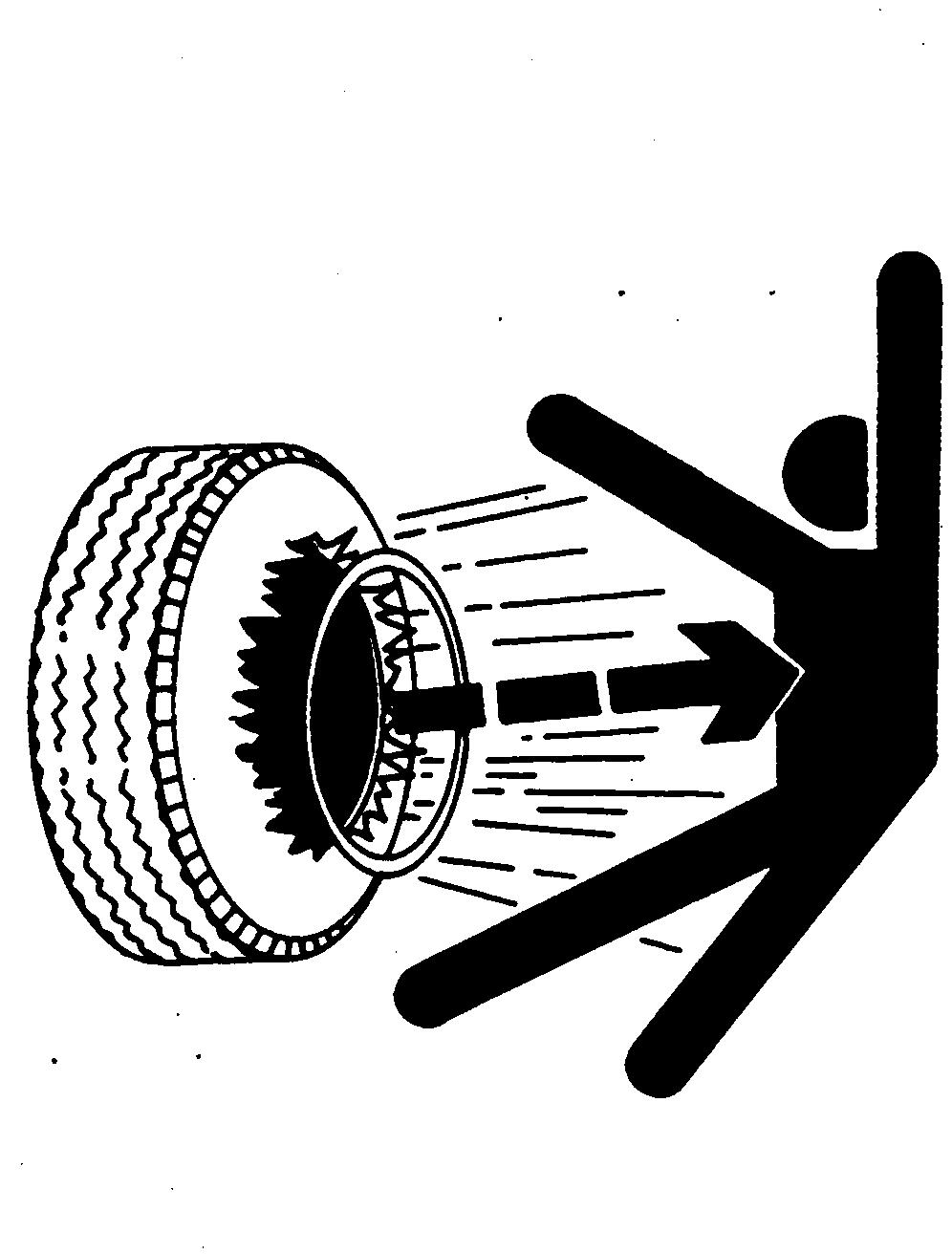

Explosiveseparationofatireandrimpartscancause seriousinjuryordeath.

Donotattempttomountatireunlessyouhavetheproper equipmentandexperiencetoperformthejob.

Alwaysmaintainthecorrecttirepressure.Donotinflate thetiresabovetherecommendedpressure.Neverweldor heatawheelandtireassembly.Theheatcancausean increaseinairpressureresultinginatireexplosion. Weldingcanstructurallyweakenordeformthewheel.

Wheninflatingtires,useaclip-onchuckandextension hoselongenoughtoallowyoutostandtoonesideand NOTinfrontoforoverthetireassembly.Useasafety cageifavailable.

Checkwheelsforlowpressure,cuts,bubbles,damaged rimsormissinglugboltsandnuts.

Avoidbreathingdustthatmaybegeneratedwhen handlingcomponentscontainingasbestosfibers.Inhaled asbestosfibersmaycauselungcancer.

Componentsinproductsthatmaycontainasbestosfibers arebrakepads,brakebandandliningassemblies,clutch plates,andsomegaskets.Theasbestosusedinthese componentsisusuallyfoundinaresinorsealedinsome way.Normalhandlingisnothazardousaslongas airbornedustcontainingasbestosisnotgenerated.

Avoidcreatingdust.Neverusecompressedairfor cleaning.Avoidbrushingorgrindingmaterialcontaining asbestos.Whenservicing,wearanapprovedrespirator.A specialvacuumcleanerisrecommendedtoclean asbestos.Ifnotavailable,applyamistofoilorwateron thematerialcontainingasbestos.

Keepbystandersawayfromthearea.

Flammablespraycanbegeneratedbyheatingnear pressurizedfluidlines,resultinginsevereburnsto yourselfandbystanders.Donotheatbywelding, soldering,orusingatorchnearpressurizedfluidlinesor otherflammablematerials.Pressurizedlinescanbe accidentallycutwhenheatgoesbeyondtheimmediate flamearea.

Avoidpotentiallytoxicfumesanddust.

Hazardousfumescanbegeneratedwhenpaintisheated bywelding,soldering,orusingatorch.

Doallworkoutsideorinawellventilatedarea.Disposeof paintandsolventproperly.

Removepaintbeforeweldingorheating:

• Ifyousandorgrindpaint,avoidbreathingthedust. Wearanapprovedrespirator.

• Ifyouusesolventorpaintstripper,removestripperwith soapandwaterbeforewelding.Removesolventor paintstrippercontainersandotherflammablematerial fromarea.Allowfumestodisperseatleast15minutes beforeweldingorheating.

Usetoolsappropriatetothework.Makeshifttoolsand procedurescancreatesafetyhazards.

Usepowertoolsonlytoloosenthreadedpartsand fasteners.

Forlooseningandtighteninghardware,usethecorrect sizetools.DONOTuseU.S.measurementtoolson metricfasteners.Avoidbodilyinjurycausedbyslipping wrenches.

UseonlyservicepartsmeetingJohnDeerespecifications.

DX,REPAIR–19–17FEB99–1/1

Improperlydisposingofwastecanthreatenthe environmentandecology.Potentiallyharmfulwasteused withJohnDeereequipmentincludesuchitemsasoil,fuel, coolant,brakefluid,filters,andbatteries.

Useleakproofcontainerswhendrainingfluids.Donotuse foodorbeveragecontainersthatmaymisleadsomeone intodrinkingfromthem.

Donotpourwasteontotheground,downadrain,orinto anywatersource.

Airconditioningrefrigerantsescapingintotheaircan damagetheEarth’satmosphere.Governmentregulations mayrequireacertifiedairconditioningservicecenterto recoverandrecycleusedairconditioningrefrigerants.

Inquireontheproperwaytorecycleordisposeofwaste fromyourlocalenvironmentalorrecyclingcenter,orfrom yourJohnDeeredealer.

DX,DRAIN–19–03MAR93–1/1

Beforereturningmachinetocustomer,makesure machineisfunctioningproperly,especiallythesafety systems.Installallguardsandshields.

MachineSpecifications

NOTE:(Specificationsanddesignsubjecttochange withoutnotice.)

ItemMeasurementSpecification

5105—3029D POWERTECH Engine, NaturallyAspirated

FactoryObservedPTOPower29.8kW(40hp)at2300rpm

MaximumEngineTorque170N•mat1400rpm

CylindersQuantity3

BoreDistance106mm(4.17in.)

StrokeDistance110mm(4.33in.)

DisplacementVolume2.9L(179cuin.)

CompressionRatio17.4:1

CylinderFiringOrder1—2—3

IntakeValveClearance0.35mm(0.014in.)

ExhaustValveClearance0.45mm(0.018in.)

SlowIdleSpeed825 ± 25rpm

FastIdleSpeed2500 ± 25rpm

OperatingRangeSpeed1400—2300rpm

InjectionPumpTimingPosition16.5° BTDC(TimeTrac)

5205—3029D POWERTECH Engine, NaturallyAspirated

FactoryObservedPTOPower35.8kW(48hp)at2300rpm

MaximumEngineTorque188N•mat1400rpm

CylindersQuantity3

ItemMeasurementSpecification

BoreDistance106mm(4.17in.)

StrokeDistance110mm(4.33in.)

DisplacementVolume2.9L(179cu.in.)

CompressionRatio17.4:1

CylinderFiringOrder1—2—3

IntakeValveClearance0.35mm(0.014in.)

ExhaustValveClearance0.45mm(0.018in.)

SlowIdleSpeed825 ± 25rpm

FastIdleSpeed2500 ± 25rpm

OperatingRangeSpeed1400—2300rpm

InjectionPumpTimingPosition16.5° BTDC(TimeTrac)

ElectricalSystem—12-Volt,Negative Ground

BatteryVoltage12-volt ColdCrankingAmps700CCA BCIGroupSize28H

AlternatorAmperage40amps

StartingMotorVoltage12volts

ItemMeasurementSpecification

PowerTake-Off

Engine—540Speed2200rpm

ItemMeasurementSpecification

HydraulicSystem

PumpDisplacement—SteeringDisplacement11.9cucm(0.73cuin.)

ItemMeasurementSpecification

PumpDisplacement—ImplementDisplacement20cucm(1.22cuin.)

Steering1 FlowRate24.6L/min.(6.5gpm)

Implement1 FlowRate41.3L/min.(10.9gpm)

Steering(Maximum)Pressure13000—13500kPa(130—135bar) (1885—1955psi)

Implement(Maximum)Pressure19000—19700kPa(190—197bar) (2755—2855psi)

HitchLiftCapacity1355kg(2990lb)

1 Flowrateat90%pumpefficiencyandengineatratedspeed.

DrainandRefillCapacities

ItemMeasurementSpecification

AG,OUO1032,2637–19–15SEP99–3/3

FuelTankCapacity85.5L(22.6gal)Approximate

CoolingSystemCapacity8.93L(2.4gal)Approximate

Crankcase(includingfilterchange)Capacity7.5L(7.9qt)Approximate

SyncReverser TransmissionCapacity33L(8.7gal)Approximate

MechanicalFrontWheelDrive (MFWD)—IfEquipped

WheelHubs(Each)Capacity0.5L(0.53qt)Approximate

AxleHousingCapacity4L(4.2qt)Approximate

SyncReverserisatrademarkofDeere&Company

AG,OUO1032,2638–19–15SEP99–1/1

MachineDimensions

NOTE:(Specificationsanddesignsubjecttochange withoutnotice.)

NOTE:Alldimensionsareofamachineequippedwith standardtires.

ItemMeasurementSpecification

5105with2-WheelDrive

StandardFrontTireSize7.5-16

StandardRearTireSize14.9-28

OverallWidth(OutsideEdgeofWidth1753mm(69.0in.)minimum Tires)

OverallLength(IncludingHitchLength2766mm(108.9in.) DraftLinks)

OverallHeightfromGround-to-TopHeight1303mm(51.3in.) ofHood

OverallHeightfromGround-to-TopHeight1551mm(61.1in.) ofSteeringWheel

OverallHeightfromGround-to-TopHeight2296mm(90.4in.) ofRoll-GardROPS

OverallHeightfromGround-to-TopHeight1900mm(74.8in.) ofFoldedROPS

OverallHeightfromGround-to-TopHeight424mm(16.7in.) ofDrawbar

OverallHeightfromHeight480mm(18.9in.)

Ground-to-CropClearance—Front Axle

CenterlineofRearAxletoFoldedDistance1257mm(49.5in.) ROPS

WheelbaseDistance1950mm(76.8in.)

TurningRadiuswithBrakesRadius2.44m(8.8ft)

TurningRadiuswithoutBrakesRadius3.29m(10.8ft)

ItemMeasurementSpecification

AverageShippingWeight,Weight1848kg(4075lb) Unballasted

5105withMFWD

StandardFrontTireSize9.5-24

StandardRearTireSize14.9-28

OverallWidth(OutsideEdgeofWidth1753mm(69.0in.)Minimum Tires)

OverallLength(IncludingHitchLength3261mm(128.4in.) DraftLinks)

OverallHeightfromGround-to-TopHeight1303mm(51.3in.) ofHood

OverallHeightfromGround-to-TopHeight1552mm(61.1in.) ofSteeringWheel

OverallHeightfromGround-to-TopHeight2296mm(90.4in.) ofRoll-GardROPS

OverallHeightfromGround-to-TopHeight1900mm(76.8in.) ofFoldedROPS

OverallHeightfromGround-to-TopHeight424mm(16.7in.) ofDrawbar

OverallHeightfromHeight368mm(14.5in.) Ground-to-CropClearance—Front Axle

CenterlineofRearAxletoFoldedDistance1257mm(49.5in.) ROPS

WheelbaseWidth1950mm(76.8in.)

TurningRadiuswithBrakes1 Radius3.02m(9.9ft)

1 WithMFWDdisengaged.

ItemMeasurementSpecification

TurningRadiuswithoutBrakesRadius3.32m(10.9ft)

AverageShippingWeight,Weight2030kg(4475lb) Unballasted

ItemMeasurementSpecification

5205with2-WheelDrive

StandardFrontTireSize7.5-16

StandardRearTireSize14.9-28

OverallWidth(OutsideEdgeofWidth1753mm(69.0in.)minimum Tires)

OverallLength(IncludingHitchLength2766mm(108.9in.) DraftLinks)

OverallHeightfromGround-to-TopHeight1303mm(51.3in.) ofHood

OverallHeightfromGround-to-TopHeight1551mm(61.1in.) ofSteeringWheel

OverallHeightfromGround-to-TopHeight2296mm(90.4in.) ofRoll-GardROPS

OverallHeightfromGround-to-TopHeight1900mm(74.8in.) ofFoldedROPS

OverallHeightfromGround-to-TopHeight424mm(16.7in.) ofDrawbar

OverallHeightfromHeight480mm(18.9in.)

Ground-to-CropClearance—Front Axle

CenterlineofRearAxletoFoldedDistance1257mm(49.5in.) ROPS

WheelbaseDistance1950mm(76.8in.)

TurningRadiuswithBrakesRadius2.44m(8.8ft)

TurningRadiuswithoutBrakesRadius3.29m(10.8ft)

ItemMeasurementSpecification

AverageShippingWeight,Weight1848kg(4075lb) Unballasted

5205withMFWD

StandardFrontTireSize9.5-24

StandardRearTireSize14.9-28

OverallWidth(OutsideEdgeofWidth1753mm(69.0in.)Minimum Tires)

OverallLength(IncludingHitchLength3261mm(128.4in.) DraftLinks)

OverallHeightfromGround-to-TopHeight1303mm(51.3in.) ofHood

OverallHeightfromGround-to-TopHeight1552mm(61.1in.) ofSteeringWheel

OverallHeightfromGround-to-TopHeight2296mm(90.4in.) ofRoll-GardROPS

OverallHeightfromGround-to-TopHeight1900mm(76.8in.) ofFoldedROPS

OverallHeightfromGround-to-TopHeight424mm(16.7in.) ofDrawbar

OverallHeightfromHeight368mm(14.5in.) Ground-to-CropClearance—Front Axle

CenterlineofRearAxletoFoldedDistance1257mm(49.5in.) ROPS

WheelbaseWidth1950mm(76.8in.)

TurningRadiuswithBrakes1 Radius3.02m(9.9ft)

1 WithMFWDdisengaged.

ItemMeasurementSpecification

TurningRadiuswithoutBrakesRadius3.32m(10.9ft)

AverageShippingWeight,Weight2030kg(4475lb) Unballasted

CED,OUO1032,2593–19–25AUG99–5/5

GroundSpeedEstimates

NOTE:GroundSpeed—km/h(mph)at2300rpmengine speed.

ItemMeasurementSpecification

RearTires—14.9-28R1

GearA-1Speed3.0km/h(1.86mph)

GearA-2Speed4.29km/h(2.67mph)

GearA-3Speed6.07km/h(3.77mph)

GearA-4Speed8.50km/h(5.28mph)

GearB-1Speed10.48km/h(6.51mph)

GearB-2Speed14.99km/h(9.32mph)

GearB-3Speed21.19km/h(13.17mph)

GearB-4Speed29.70km/h(18.46mph)

GearR-1Speed3.58km/h(2.23mph)

GearR-2Speed5.12km/h(3.18mph)

GearR-3Speed7.24km/h(4.50mph)

GearR-4Speed10.15km/h(6.31mph)

RearTires—16.9-28R1

GearA-1Speed3.14km/h(1.94mph)

GearA-2Speed4.48km/h(2.79mph)

GearA-3Speed6.34km/h(3.94mph)

GearA-4Speed8.88km/h(5.52mph)

GearB-1Speed10.95km/h(6.80mph)

GearB-2Speed15.66km/h(9.74mph)

GearB-3Speed22.14km/h(13.76mph)

ItemMeasurementSpecification

GearB-4Speed31.04km/h(19.29mph)

GearR-1Speed3.74km/h(2.33mph)

GearR-2Speed5.35km/h(3.32mph)

GearR-3Speed7.56km/h(4.70mph)

GearR-4Speed10.61km/h(6.59mph)

RearTires—13.6-28R1

GearA-1Speed2.87km/h(1.78mph)

GearA-2Speed4.11km/h(2.56mph)

GearA-3Speed5.82km/h(3.62mph)

GearA-4Speed8.15km/h(5.06mph)

GearB-1Speed10.05km/h(6.24mph)

GearB-2Speed14.38km/h(8.94mph)

GearB-3Speed20.32km/h(12.63mph)

GearB-4Speed28.48km/h(17.70mph)

GearR-1Speed3.43km/h(2.14mph)

GearR-2Speed4.16km/h(3.05mph)

GearR-3Speed6.94km/h(4.32mph)

GearR-4Speed9.73km/h(6.05mph)

RearTires—16.9-24R1

GearA-1Speed2.91km/h(1.80mph)

GearA-2Speed4.16km/h(2.59mph)

GearA-3Speed5.89km/h(3.66mph)

GearA-4Speed8.24km/h(5.12mph)

AG,OUO1032,2653–19–23SEP99–2/6

ItemMeasurementSpecification

GearB-1Speed10.16km/h(6.32mph)

GearB-2Speed14.54km/h(9.04mph)

GearB-3Speed20.55km/h(12.77mph)

GearB-4Speed28.80km/h(17.90mph)

GearR-1Speed3.47km/h(2.16mph)

GearR-2Speed4.97km/h(3.08mph)

GearR-3Speed7.02km/h(4.37mph)

GearR-4Speed9.85km/h(6.12mph)

RearTires—16.9-24R3

GearA-1Speed2.86km/h(1.77mph)

GearA-2Speed4.09km/h(2.55mph)

GearA-3Speed5.79km/h(3.60mph)

GearA-4Speed8.11km/h(5.04mph)

GearB-1Speed10.00km/h(6.21mph)

GearB-2Speed14.30km/h(8.89mph)

GearB-3Speed20.22km/h(12.56mph)

GearB-4Speed28.33km/h(17.61mph)

GearR-1Speed3.42km/h(2.13mph)

GearR-2Speed4.88km/h(3.03mph)

GearR-3Speed6.91km/h(4.29mph)

GearR-4Speed9.68km/h(6.02mph)

RearTires—16.9-24R4

GearA-1Speed2.87km/h(1.78mph)

ItemMeasurementSpecification

GearA-2Speed4.10km/h(2.55mph)

GearA-3Speed5.80km/h(2.25mph)

GearA-4Speed8.13km/h(5.05mph)

GearB-1Speed10.02km/h(6.22mph)

GearB-2Speed14.33km/h(8.91mph)

GearB-3Speed20.26km/h(12.59mph)

GearB-4Speed28.39km/h(17.65mph)

GearR-1Speed3.42km/h(2.13mph)

GearR-2Speed4.89km/h(3.04mph)

GearR-3Speed6.92km/h(4.30mph)

GearR-4Speed9.70km/h(6.03mph)

RearTires—21.5L-16.1R3

GearA-1Speed2.27km/h(1.41mph)

GearA-2Speed3.25km/h(2.02mph)

GearA-3Speed4.59km/h(2.85mph)

GearA-4Speed6.43km/h(4.00mph)

GearB-1Speed7.93km/h(4.93mph)

GearB-2Speed11.35km/h(7.06mph)

GearB-3Speed16.04km/h(10.50mph)

GearB-4Speed22.48km/h(13.97mph)

GearR-1Speed2.71km/h(1.69mph)

GearR-2Speed3.88km/h(2.41mph)

GearR-3Speed5.48km/h(3.41mph)

GearR-4Speed7.68km/h(4.78mph)

ItemMeasurementSpecification

RearTires—22.5LL-16.1TurfSpecial

GearA-1Speed2.78km/h(1.72mph)

GearA-2Speed3.97km/h(2.47mph)

GearA-3Speed5.61km/h(3.49mph)

GearA-4Speed7.86km/h(4.88mph)

GearB-1Speed9.69km/h(6.02mph)

GearB-2Speed13.87km/h(8.62mph)

GearB-3Speed19.60km/h(12.18mph)

GearB-4Speed27.47km/h(17.08mph)

GearR-1Speed3.31km/h(2.06mph)

GearR-2Speed4.74km/h(2.94mph)

GearR-3Speed6.70km/h(4.16mph)

GearR-4Speed9.39km/h(5.84mph)

RearTires—19.5L-24R4

GearA-1Speed2.85km/h(1.77mph)

GearA-2Speed4.08km/h(2.54mph)

GearA-3Speed5.77km/h(3.51mph)

GearA-4Speed8.08km/h(5.02mph)

GearB-1Speed9.96km/h(6.18mph)

GearB-2Speed14.24km/h(8.85mph)

GearB-3Speed20.13km/h(12.51mph)

GearB-4Speed28.22km/h(17.54mph)

GearR-1Speed3.40km/h(2.12mph)

GearR-2Speed4.86km/h(3.02mph)

ItemMeasurementSpecification

GearR-3Speed6.88km/h(4.28mph)

GearR-4Speed9.64km/h(5.99mph)

RearTires—14.9-24R1

GearA-1Speed2.73km/h(1.69mph)

GearA-2Speed3.90km/h(2.43mph)

GearA-3Speed5.52km/h(3.43mph)

GearA-4Speed7.73km/h(4.80mph)

GearB-1Speed9.53km/h(5.92mph)

GearB-2Speed13.63km/h(8.47mph)

GearB-3Speed19.26km/h(11.97mph)

GearB-4Speed27.00km/h(16.78mph)

GearR-1Speed3.25km/h(2.03mph)

GearR-2Speed4.65km/h(2.89mph)

GearR-3Speed6.58km/h(4.09mph)

GearR-4Speed9.23km/h(5.74mph)

AG,OUO1032,2653–19–23SEP99–6/6

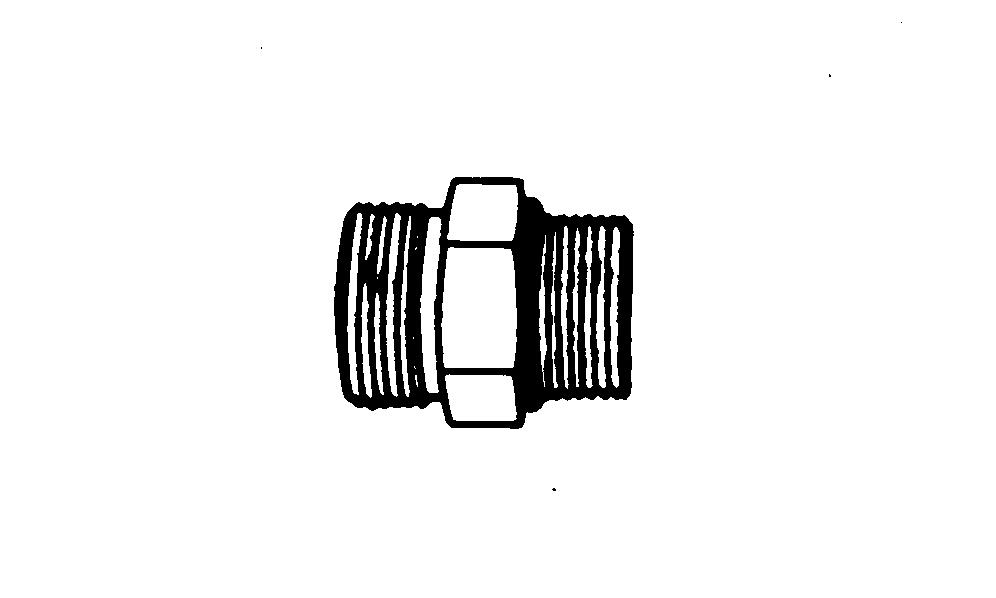

ServiceRecommendationsforO-RingBoss Fittings

1.InspectO-ringbossseatfordirtordefects.

2.LubricateO-ringwithpetroleumjelly.Placeelectrical tapeoverthreadstoprotectO-ring.SlideO-ringover tapeandintoO-ringgrooveoffitting.Removetape.

3.Tightenfittingtotorquevalueshownonchart.

04T,90,K66–19–19MAR96–1/2

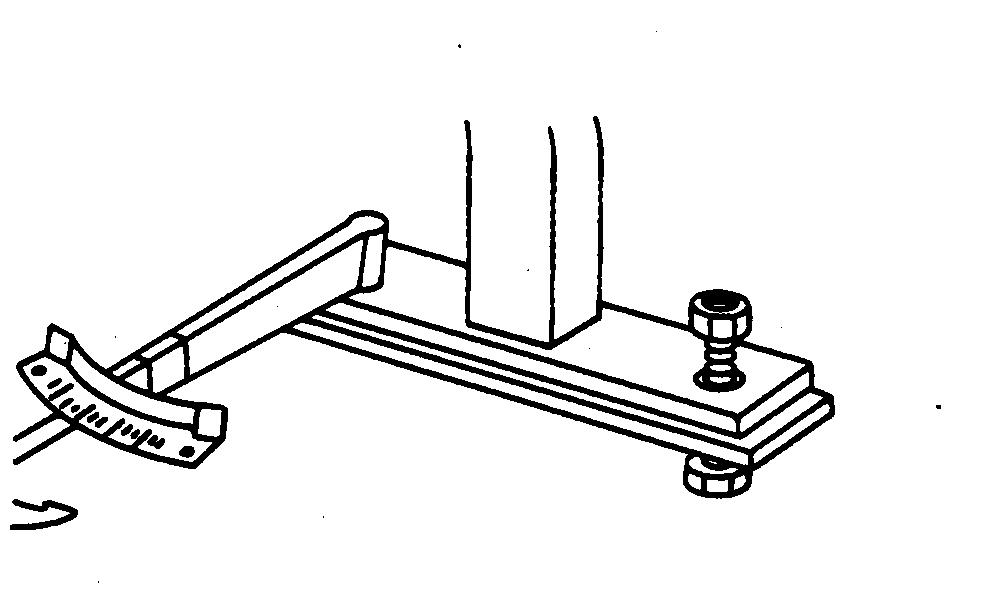

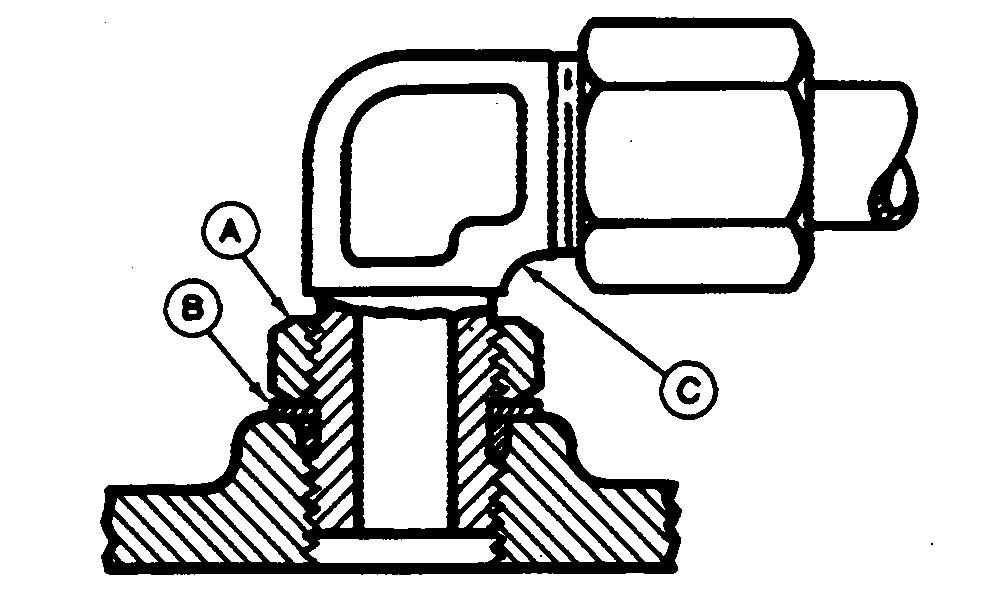

1.Back-offlocknut(A)andback-upwasher(B) completelytohead-end(C)offitting.

2.Turnfittingintothreadedbossuntilback-upwasher contactsfaceofboss.

3.Turnfittinghead-endcounterclockwisetoproperindex (maximumofoneturn).

NOTE:Donotallowhosestotwistwhentightening fittings.

4.Holdfittinghead-endwithawrenchandtightenlocknut andback-upwashertopropertorquevalue.

STRAIGHTFITTINGORSPECIALNUTTORQUECHART

ThreadSizeN•mlb-ft

3/8-24UNF86

7/16-20UNF129

1/2-20UNF1612

9/16-18UNF2418

3/4-16UNF4634

7/8-14UNF6246

1-1/16-12UN10275

1-3/16-12UN12290

1-5/16-12UN142105

1-5/8-12UN190140

1-7/8-12UN217160

NOTE:Torquetoleranceis ± 10%.

1.Inspectthefittingsealingsurfaces.Theymustbefree ofdirtordefects.

2.InspecttheO-ring.Itmustbefreeofdamageor defects.

3.LubricateO-ringsandinstallintogrooveusing petroleumjellytoholdinplace.

4.PushO-ringintothegroovewithplentyofpetroleum jellysoO-ringisnotdisplacedduringassembly.

5.Indexanglefittingsandtightenbyhandpressingjoint togethertoinsureO-ringremainsinplace.

6.Tightenfittingornuttotorquevalueshownonthe chartperdashsizestampedonthefitting.Donotallow hosestotwistwhentighteningfittings.

FLATFACEO-RINGSEALFITTINGTORQUE

6.350.250-49/16-1816125.03.5 9.520.375-611/16-1624189.06.5 12.700.500-813/16-16503717.012.5 15.880.625-101-14695117.012.5

19.050.750-1213/16-121027517.012.5 22.220.875-1413/16-121027517.012.5

25.401.000-1617/16-1214210517.012.5 31.751.250-20111/16-1219014017.012.5 38.101.500-242-1221716017.012.5

NOTE:Torquetoleranceis+15-20%.

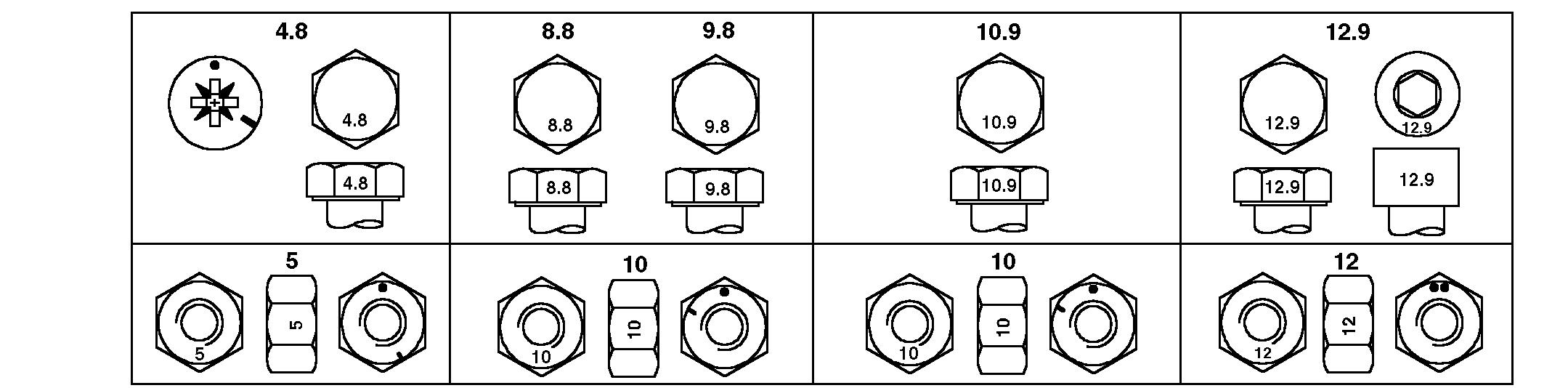

M64.7(3.5)6(4.4)9(6.6)11.5(8.5)13(9.5)16.5(12.2)15.5(11.5)19.5(14.5)

M811.5(8.5)14.5(10.7)22(16)28(20.5)32(23.5)40(29.5)37(27.5)47(35) M1023(17)29(21)43(32)55(40)63(46)80(59)75(55)95(70) M1240(29.5)50(37)75(55)95(70)110(80)140(105)130(95)165(120) M1463(46)80(59)120(88)150(110)175(130)220(165)205(150)260(190) M16100(74)125(92)190(140)240(175)275(200)350(255)320(235)400(300) M18135(100)170(125)265(195)330(245)375(275)475(350)440(325)560(410) M20190(140)245(180)375(275)475(350)530(390)675(500)625(460)790(580) M22265(195)330(245)510(375)650(480)725(535)920(680)850(625)1080(800) M24330(245)425(315)650(480)820(600)920(680)1150(850)1080(800)1350(1000) M27490(360)625(460)950(700)1200(885)1350(1000)1700(1250)1580(1160)2000(1475) M30660(490)850(625)1290(950)1630(1200)1850(1350)2300(1700)2140(1580)2700(2000)

M33900(665)1150(850)1750(1300)2200(1625)2500(1850)3150(2325)2900(2150)3700(2730) M361150(850)1450(1075)2250(1650)2850(2100)3200(2350)4050(3000)3750(2770)4750(3500)

a "Lubricated"meanscoatedwithalubricantsuchasengineoil,orfastenerswithphosphateandoilcoatings.

b "Dry"meansplainorzincplatedwithoutanylubrication.

DONOTusethesevaluesifadifferenttorquevalueortighteningMakesurefastenerthreadsarecleanandthatyouproperlystart procedureisgivenforaspecificapplication.Torquevalueslistedarethreadengagement.Thiswillpreventthemfromfailingwhen forgeneraluseonly.Checktightnessoffastenersperiodically.tightening.

Shearboltsaredesignedtofailunderpredeterminedloads.AlwaysTightenplasticinsertorcrimpedsteel-typelocknutstoapproximately replaceshearboltswithidenticalpropertyclass.50percentofthedrytorqueshowninthechart,appliedtothenut, nottothebolthead.Tightentoothedorserrated-typelocknutstothe fulltorquevalue.

Fastenersshouldbereplacedwiththesameorhigherpropertyclass. Ifhigherpropertyclassfastenersareused,theseshouldonlybe tightenedtothestrengthoftheoriginal.

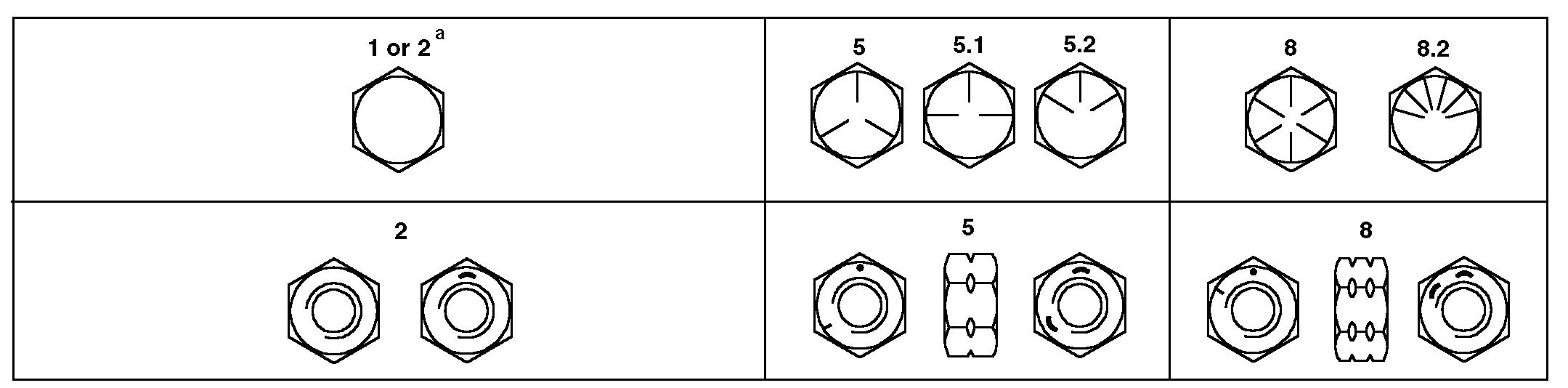

1/43.8(2.8)4.7(3.5)6(4.4)7.5(5.5)9.5(7)12(9)13.5(10)17(12.5) 5/167.7(5.7)9.8(7.2)12(9)15.5(11.5)19.5(14.5)25(18.5)28(20.5)35(26) 3/813.5(10)17.5(13)22(16)27.5(20)35(26)44(32.5)49(36)63(46) 7/1622(16)28(20.5)35(26)44(32.5)56(41)70(52)80(59)100(74) 1/234(25)42(31)53(39)67(49)85(63)110(80)120(88)155(115) 9/1648(35.5)60(45)76(56)95(70)125(92)155(115)175(130)220(165) 5/867(49)85(63)105(77)135(100)170(125)215(160)240(175)305(225) 3/4120(88)150(110)190(140)240(175)300(220)380(280)425(315)540(400) 7/8190(140)240(175)190(140)240(175)490(360)615(455)690(510)870(640) 1285(210)360(265)285(210)360(265)730(540)920(680)1030(760)1300(960) 1-1/8400(300)510(375)400(300)510(375)910(670)1150(850)1450(1075)1850(1350) 1-1/4570(420)725(535)570(420)725(535)1280(945)1630(1200)2050(1500)2600(1920) 1-3/8750(550)950(700)750(550)950(700)1700(1250)2140(1580)2700(2000)3400(2500) 1-1/2990(730)1250(930)990(730)1250(930)2250(1650)2850(2100)3600(2650)4550(3350)

a Grade2appliesforhexcapscrews(nothexbolts)upto6in.(152mm)long.Grade1appliesforhexcapscrewsover6in.(152mm)long, andforallothertypesofboltsandscrewsofanylength.

b "Lubricated"meanscoatedwithalubricantsuchasengineoil,orfastenerswithphosphateandoilcoatings.

c "Dry"meansplainorzincplatedwithoutanylubrication.

DONOTusethesevaluesifadifferenttorquevalueortighteningMakesurefastenerthreadsarecleanandthatyouproperlystart procedureisgivenforaspecificapplication.Torquevalueslistedarethreadengagement.Thiswillpreventthemfromfailingwhen forgeneraluseonly.Checktightnessoffastenersperiodically.tightening.

Shearboltsaredesignedtofailunderpredeterminedloads.AlwaysTightenplasticinsertorcrimpedsteel-typelocknutstoapproximately replaceshearboltswithidenticalgrade.50percentofthedrytorqueshowninthechart,appliedtothenut, nottothebolthead.Tightentoothedorserrated-typelocknutstothe fulltorquevalue. Fastenersshouldbereplacedwiththesameorhighergrade.If highergradefastenersareused,theseshouldonlybetightenedto thestrengthoftheoriginal.

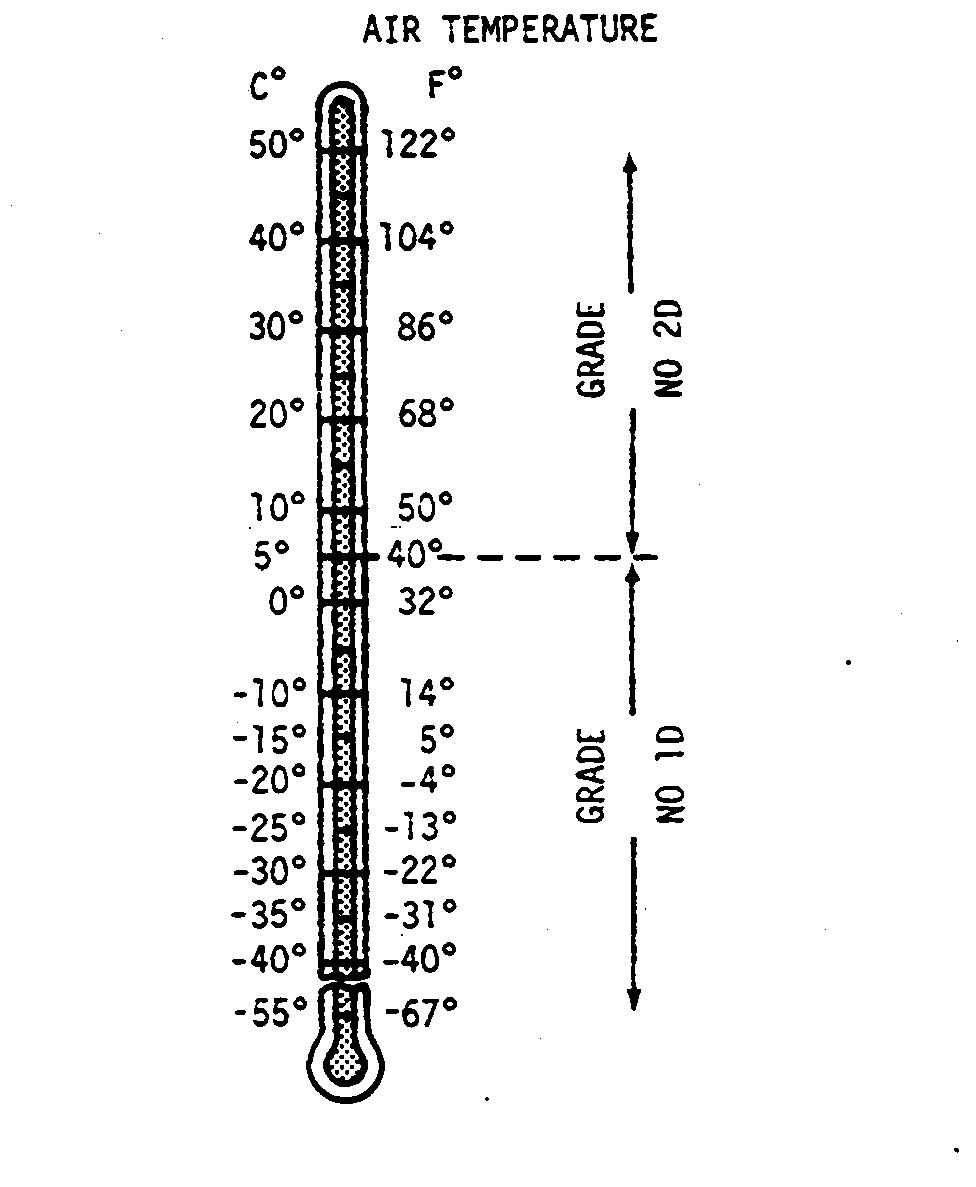

UseeitherGradeNo.1-DorGradeNo.2-Dfuelas definedbyASTMDesignationD975fordieselfuels.Find expectedairtemperatureattimeofstartonthermometer scaleinchart.Correctdieselfuelgradeisshowntothe rightofscale.

NOTE:Ataltitudesabove1500m(5000ft)usegrade1-D foralltemperatures.

Fuelsulphurcontentshouldbelessthan1.0percent preferablylessthan0.5percent.Dieselfuelhaving sulphurcontenthigherthan1.0percentmaycause increasewearonmetalenginepartsbecauseofacids producedbysulphurduringcombustion.

IMPORTANT:Iffuelsulphurcontentexceeds0.7 percent,theengineoildraininterval mustbereducedby50percentto125 hours.

Cetanenumbershouldbenolessthan40toassure satisfactorystartingandoverallperformance.

Cloudpointshouldbeatleast6°C(10°F)belowlowest expectedairtemperatureattimeofstarting.Waxcan separatefromfuelwhentemperaturedecreasestocloud pointandmayplugfilter.

Ifyouoperateyourtractorattemperaturesbelowthe limitsshown,consultyourdealerforspeciallubricantsand startingaids.

Buygoodquality,cleanfuelfromareputablesupplier.

Properfuelstorageiscriticallyimportant.Useclean storageandtransfertanks.Periodicallydrainwaterand sedimentfrombottom.

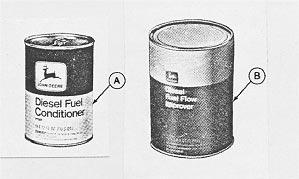

Avoidstoringfueloverlongperiodsoftime.Ifthereisa veryslowturnoveroffuelinthefueltankorsupplytank,it maybenecessarytoaddJohnDeereDieselFuel Conditioner(A)topreventwatercondensation.(Seeyour JohnDeeredealerforproperserviceormaintenance recommendations.)

Storefuelinaconvenientplaceawayfrombuildings.

NOTE:Toreducefuelgellingandcontrolwaxseparation duringcoldweather,JohnDeereFuelFlow Improver(B),orequivalent,maybeaddedtofuel orbulkstoragetank.

A—JohnDeereDieselFuelConditioner

B—JohnDeereFuelFlowImprover

MX,FLIP,AA1–19–26JUL94–1/1

DoNotUseGalvanizedContainers

IMPORTANT:Dieselfuelstoredingalvanized containersreactswithzinccoating onthecontainertoformzincflakes. Iffuelcontainswater,azincgelwill alsoform.Thegelandflakeswill quicklyplugfuelfiltersanddamage fuelinjectorsandfuelpumps.

DONOTUSEagalvanizedcontainertostorediesel fuel.

Storefuelin:

• plasticcontainers.

• aluminumcontainers.

• speciallycoatedsteelcontainersmadefordiesel fuel.

DONOTUSEbrass-coatedcontainers:brassisan alloyofcopperandzinc.

CAUTION:Handlefuelcarefully.Donotrefuel themachinewhilesmokingorwhennearopen flameorsparks.

Alwaysstopenginebeforerefuelingmachine.

Fillfueltankatendofeachday’soperation.Fillfueltank onlytobottomoffillerneck.

Thetractor’sfueltankcanbefilledfromtheleftorright sideoftractor.

Specification

IMPORTANT:Thefueltankusesventedfillercaps.If anewfillercapisrequired,always replaceitwithaventedcap.

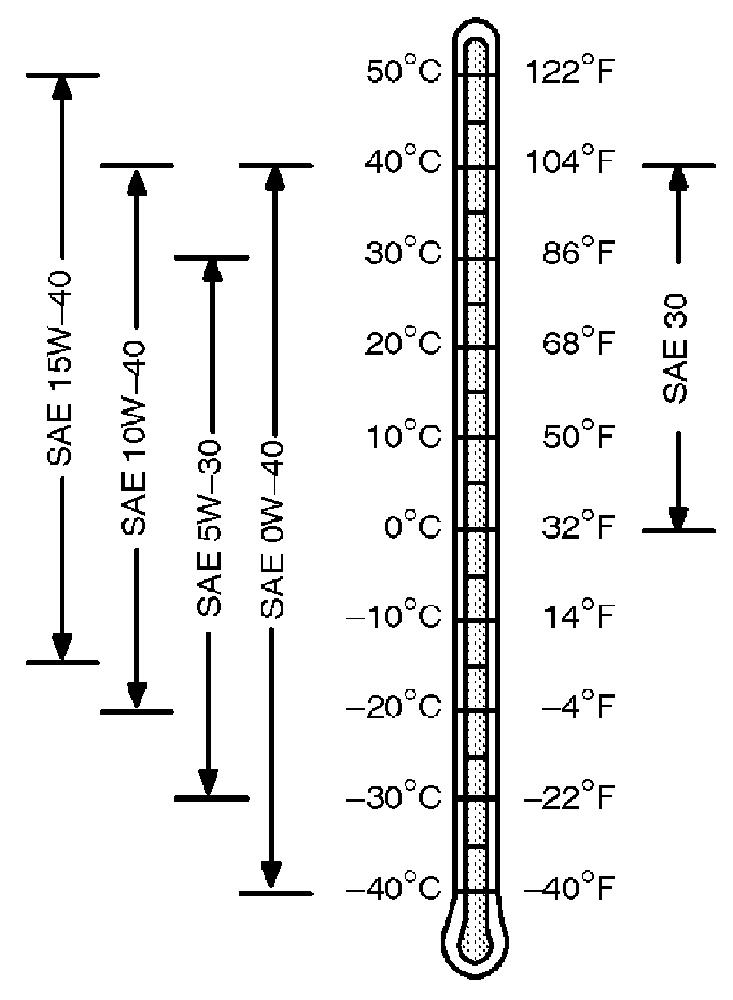

Useoilviscositybasedontheexpectedairtemperature rangeduringtheperiodbetweenoilchanges.

Thefollowingoilispreferred:

• JohnDeerePLUS-50

Thefollowingoilisalsorecommended:

• JohnDeereTORQ-GARDSUPREME

Otheroilsmaybeusediftheymeetoneormoreofthe following:

• APIServiceClassificationCG-4

• APIServiceClassificationCF-4

• ACEASpecificationE3

• ACEASpecificationE2

Multi-viscositydieselengineoilsarepreferred. Ifdieselfuelwithsulfurcontentgreaterthan0.5%isused, reducetheserviceintervalby50%.

ExtendedserviceintervalsmayapplywhenJohnDeere preferredengineoilsareused.ConsultyourJohnDeere dealerformoreinformation.

JohnDeereLowSilicateAntifreezeisrecommended.

Alsorecommendedislowsilicateantifreezeformulated toGM6038Morequivalent.

Otherantifreezesthatmaybeused:

• Ethylene-glycoltype.

• Thosecontainingnotmorethan0.1percent anhydrousmetasilicate.

• ThosemeetingGeneralMotorsPerformance SpecificationGM1899M

IMPORTANT:Sometypesofethylene-glycol antifreezeareintendedfor automotiveuse.Theseproductsare oftenlabeledforuseinaluminum enginesandusuallycontainmore than0.1percentofanhydrous metasilicate.

JohnDeereLiquidCoolantConditionerisrecommended forwet-sleevedieselenginesnothavingacoolantfilter option.Otherconditionersmaybeusedifitcontains non-chromateinhibitors.

IMPORTANT:IfengineisequippedwithaJohnDeere CoolantFilterConditioner,thecorrect inhibitorsarecontainedinthefilter.If bothareused,agel-typedepositis createdwhichcouldinhibitheat transferandblockcoolantflow.John DeereLiquidCoolantConditionerdoes notprotectagainstfreezing.

Varioussizesofcoolantconditionersareavailablefrom yourJohnDeeredealer.

Checkcontainerlabelorconsultwithantifreeze supplierbeforeusing.

Mix50-67percentlowsilicateantifreezewith33-50 percentdistilledordeionizedwater.

Lowsilicateantifreezeprovides:

• Adequateheattransfer.

• Corrosion-resistantenvironmentwithinthecooling system.

• Compatibilitywithcoolingsystemhoseandseal material.

• Protectionduringcoldandhotweatheroperations.

DX,COOL–19–04JUN90–1/1

Certaingeographicalareasmayrequirespecial antifreezeorcoolantpractices.Ifyouhaveany questions,consultyourauthorizedservicingdealerto obtainthelatestinformationandrecommendations. DX,COOL1–19–04JUN90–1/1

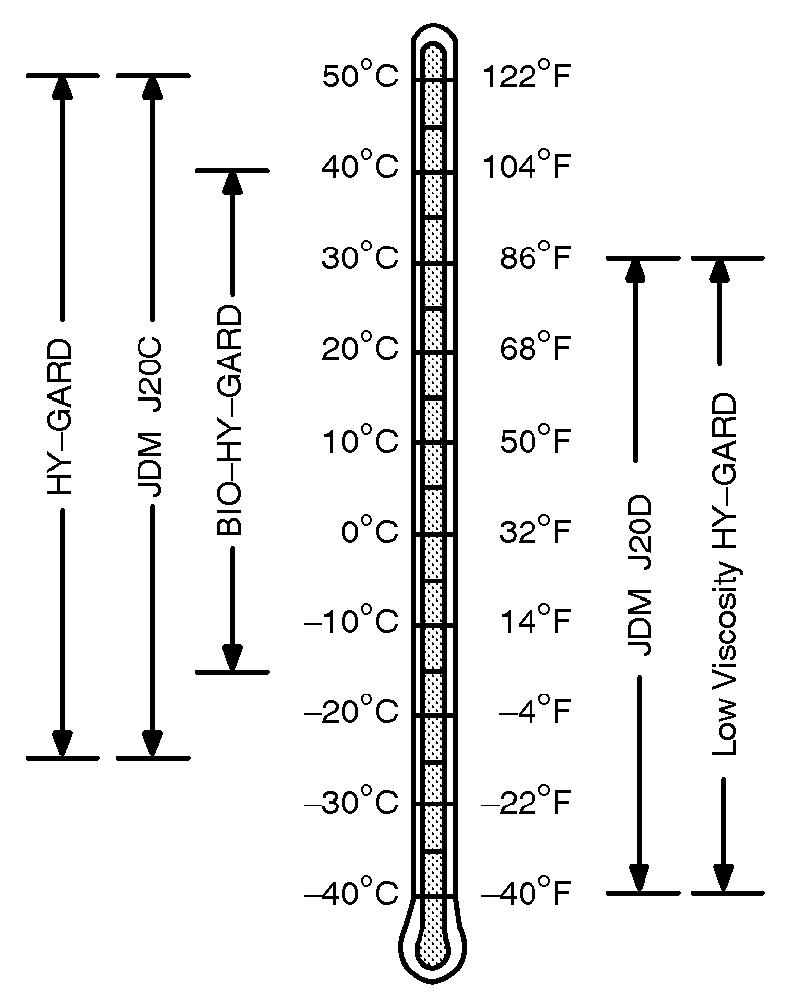

Useoilviscositybasedontheexpectedairtemperature rangeduringtheperiodbetweenoilchanges.

Thefollowingoilsarepreferred:

• JohnDeereHY-GARDHY-GARD

• JohnDeereLowViscosityHY-GARDHY-GARD

Otheroilsmaybeusediftheymeetoneofthefollowing:

• JohnDeereStandardJDMJ20C

• JohnDeereStandardJDMJ20D

Usethefollowingoilwhenabiodegradablefluidis required:

• JohnDeereBIO-HY-GARD1

HY-GARDisaregisteredtrademarkofDeere&Company. BIO-HY-GARDisatrademarkofDeere&Company.

1BIO-HY-GARDmeetsorexceedstheminimumbiodegradabilityof80% within21daysaccordingtoCEC-L-33-T-82testmethod.BIO-HY-GARD shouldnotbemixedwithmineraloilsbecausethisreducesthe biodegradabilityandmakesproperoilrecyclingimpossible.

DX,ANTI–19–10OCT97–1/1

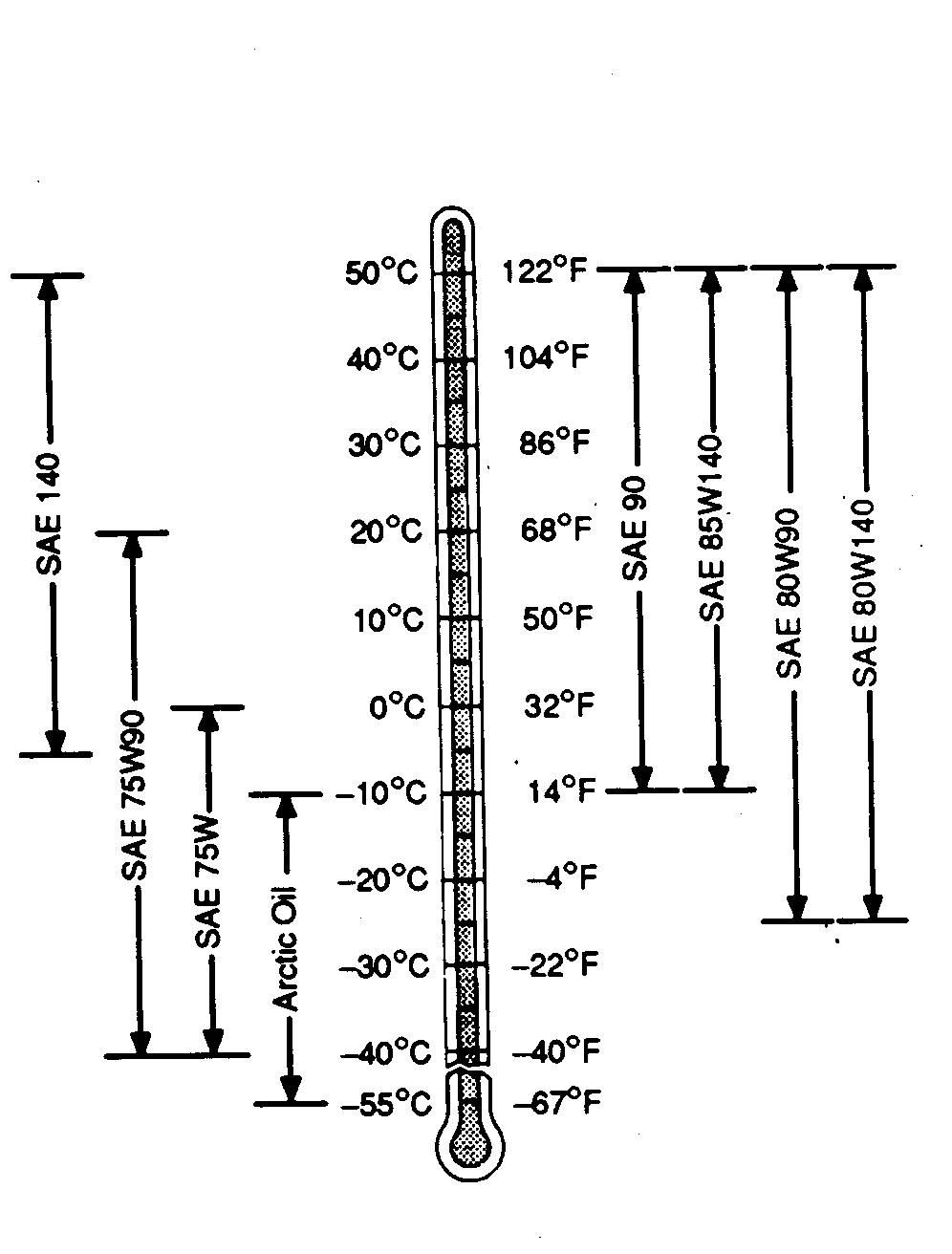

Useoilviscositybasedontheexpectedairtemperature rangeduringtheperiodbetweenoilchanges.

JohnDeereGL-5GearLubricantisrecommended.

Otheroilsmaybeusediftheymeetoneormoreofthe following:

• APIServiceClassificationGL-5

• MilitarySpecificationMIL-L-2105D

• MilitarySpecificationMIL-L-2105C

• MilitarySpecificationMIL-L-2105B

OilsmeetingMilitarySpecificationMIL-L-10324Amaybe usedasarcticoils.

LV,1020HA,A3–19–19JAN95–1/1

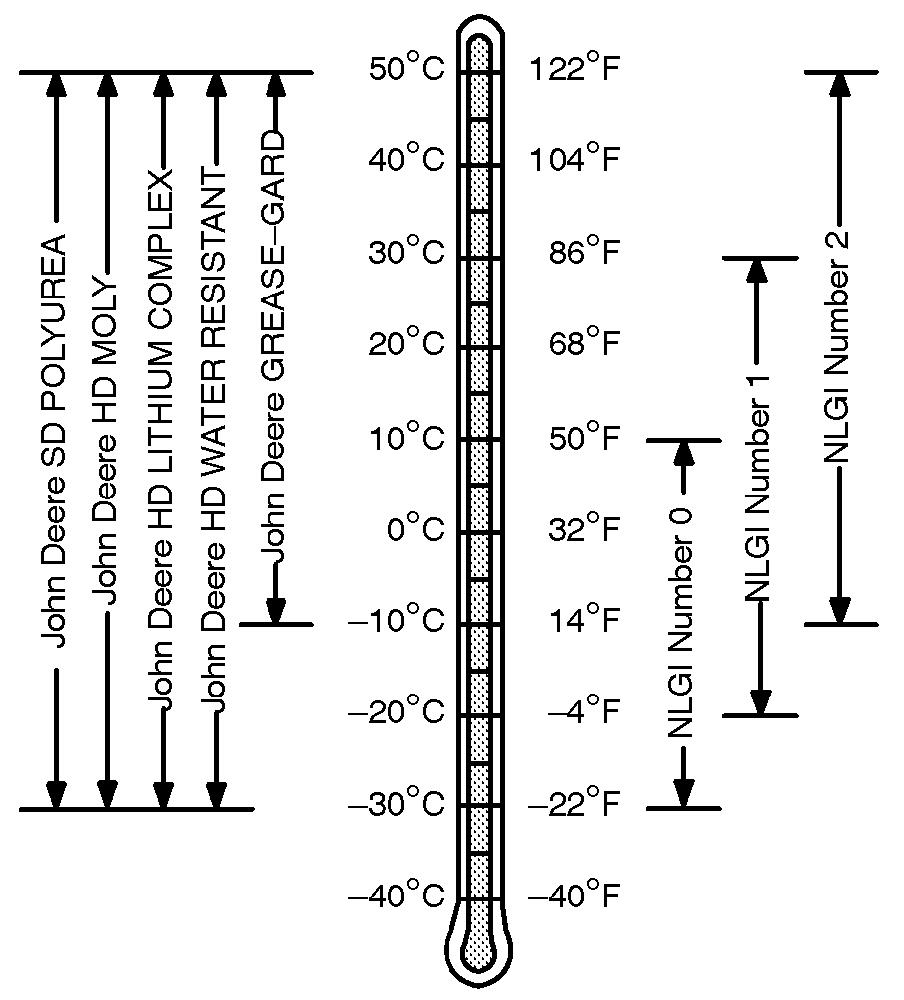

Grease(SpecificApplication)

LithiumGreasewithMolybdenumDisulphideis recommendedforuseoninternalcomponentsof transmission.

TY6333orTY6347JohnDeereMolyHighTemperature EPGreaseisrecommendedforuseonthetractionclutch andPTOclutchsplines.

LV,1020HA,A4–19–27JUN94–1/1

UsegreasebasedonNLGIconsistencynumbersandthe expectedairtemperaturerangeduringtheserviceinterval.

Thefollowinggreasesarepreferred:

• JohnDeereSDPOLYUREAGREASE

Thefollowinggreasesarealsorecommended:

• JohnDeereHDMOLYGREASE

• JohnDeereHDLITHIUMCOMPLEXGREASE

• JohnDeereHDWATERRESISTANTGREASE

• JohnDeereGREASE-GARD

Othergreasesmaybeusediftheymeetthefollowing:

• NLGIPerformanceClassificationGC-LB

IMPORTANT:Sometypesofgreasethickenerarenot compatiblewithothers.

DX,GREA1–19–07JUL99–1/1

Conditionsincertaingeographicalareasmayrequire lubricantrecommendationsdifferentfromthoseprintedin thismanual.

SomeJohnDeerebrandcoolantsandlubricantsmaynot beavailableinyourlocation.

ConsultyourJohnDeeredealertoobtaininformationand recommendations.

Syntheticlubricantsmaybeusediftheymeetthe performancerequirementsasshowninthismanual.

Thetemperaturelimitsandserviceintervalsshowninthis manualapplytobothconventionalandsyntheticoils.

Re—refinedbasestockproductsmaybeusedifthe finishedlubricantmeetstheperformancerequirements.

DX,ALTER–19–18MAR96–1/1

Yourequipmentcanoperateattopefficiencyonly whencleanlubricantsareused.

Usecleancontainerstohandlealllubricants.

Wheneverpossible,storelubricantsandcontainersin anareaprotectedfromdust,moisture,andother contamination.Storecontainersontheirsidetoavoid wateranddirtaccumulation.

Makecertainthatallcontainersareproperlymarkedto identifytheircontents.

Properlydisposeofalloldcontainersandanyresidual lubricanttheymaycontain.

Whenworkingonmachinesorcomponentsthatare coveredbywarranty,itisIMPORTANTthatyouinclude themachine’sProductIdentificationNumberandthe componentserialnumberonthewarrantyclaimform.

Thelocationofcomponentserialnumberplatesare shownbelow.

Theproductidentificationnumber(PIN)plate(A)is locatedontheright-handsideofthefrontsupport.

A—ProductIdentificationNumberPlate

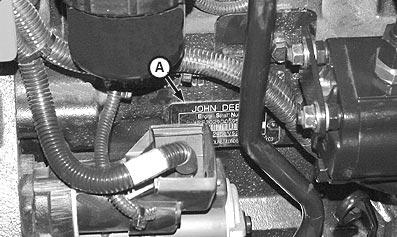

Theengineserialnumberplate(A)islocatedonthe right-handsideoftheengineblock,betweenthestarter andthehydraulicpump.

A—EngineSerialNumberPlate

FuelInjectionPumpSerialNumberLocation

Thefuelinjectionpumpserialnumberplate(A)islocated onthesideofthepump.

A—FuelInjectionPumpSerialNumberPlate

AlternatorSerialNumberLocation

Thealternatorserialnumberplate(A)islocatedonthe sideofthehousing.

1—AlternatorSerialNumberPlate

AG,OUO1032,2847–19–18JAN00–1/1

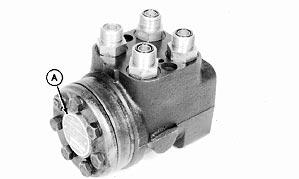

PowerSteeringValveSerialNumber Location

Thepowersteeringvalveserialnumberplate(A)is locatedonthebottomofthevalve.

AG,OUO1032,2849–19–18JAN00–1/1

StarterSerialNumberLocation

Thestarterserialnumberplate(A)islocatedontheside ofthehousing.

A—StarterSerialNumberPlate

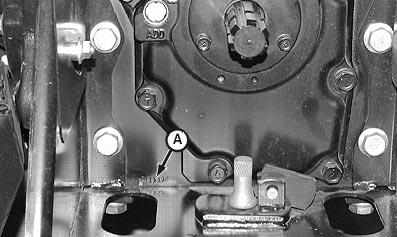

TransmissionSerialNumberLocation

Thetransmission(drivetrain)serialnumber(A)islocated attherearofthemachineonthebottomleft-handcorner ofthedifferentialhousing.

A—TransmissionSerialNumber

AG,OUO1032,2850–19–18JAN00–1/1

AG,OUO1032,2851–19–18JAN00–1/1

FrontAxle(2WD)SerialNumberLocation

The2-WDfrontaxleserialnumberplate(A)islocatedon therearright-handsideoftheaxle.

A—2-WDFrontAxleSerialNumberPlate

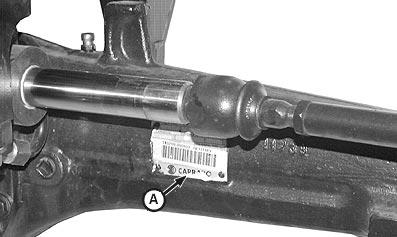

MechanicalFrontWheelDrive(MFWD)Serial NumberLocation

TheMFWDserialnumberplate(A)islocatedontherear sideoftheright-handaxlehousing.

A—MFWDSerialNumberPlate

Theinformationcoveredinthisgrouppertainstothe featuresofthemachinescoveredinthisTechnical Manual.Itcanbeusedinadditiontothenormal advertisingliteratureormayhelpindeterminingwhich specificfeaturerequiresservice.Alistofalltheavailable accessoriesandkitsisalsoincluded.

LV,1030HA,A2–19–07MAY96–1/1

StandardFeatures

JohnDeere3000SeriesEngine

• 5105—PE3029DLV5134kw(45.6hp)

• 5205—PE3029DLV5239kw(53hp)

• 3cylinderdieselengine

• Wetsleeved

• Directinjection

• Keyswitchcontrolledfuelshut-off

• Naturallyaspirated

• Verticalexhaust

SyncReverser Transmission

• Eightspeedsforward,fourreverse

• Inboardplanetaryfinaldrives

• Differentiallock

DualClutch

• ProvidescontinuouslivePTO

• StopstractorwithoutdisengagingPTO PTO

• Rear,540rpm

• Fullyindependentclutch

HydrostaticPowerSteering

• Powerissuppliedbyatandemgearhydraulicpump mountedtotheengine

MechanicalBrakes

• Wetdisk

• Individuallymechanicallycontrolled

Open-CenterHydraulicSystem

• Tandemgearhydraulicpumps

• Pumpsaredrivendirectlyoffenginetiminggears

• Therearpumpsuppliesoiltothepowersteeringand lubricatestopshaftofthetransmission.

• Thefrontpumpsuppliesoiltotherockshaftandthe selectivecontrolvalves,ifequipped.

Axles

• Adjustablefrontaxleisstandard

Hitch

• CategoryIIthree-pointhitch

• Positioncontrollever

• Rateofdropcontrollever

PTOWarningSystem

• Warningalarmsoundsfor8—10secondswhen operatorleavesseatwithPTOengaged.Engineand PTOcontinuetorun.

FixedROPS

Retractableseatbelt

• Protectsoperatorintheeventofatip-over

AG,OUO1032,2854–19–18JAN00–2/2

FactoryInstalledOptionalEquipment

MechanicalFrontWheelDrive(MFWD)Axle

• Centerlinedesign

• Highpivotpointforbettergroundclearanceandaxle oscillation

Mid-MountvalveandCouplers(forfrontloader applications)

• Floatandregenerativespoolvalves

• Onelever“joystick”control

SingleSelectiveControlValve(SCV)

• Floatspoolvalve

DualSelectiveControlValve(SCV)

• Floatspoolvalve

• Regenerativespoolvalve

Hitch

• Rockshaftwithdraftandpositioncontrol

• Telescopingdraftlinks

Coldweatherpackage(IncludestheFollowing)

• 900CCAbattery

• Enginecoolantheater

• Heavydutyintakeheater

FoldableROPS

• SingleortwoSelectiveControlValve(SCV)

• Mid-mountValveandJoystick

• PowerBeyondKit

• PowerBeyondEndCap

• ColdWeatherPackage

• FrontDriveShaftCoupler

• SeatArmRests

• Horn

• FrontWeightBracketandWeights

• DeluxeCanopy(usedonfoldableROPSonly.)

• Interchangeable,Category2-to-Category1Hitch Bushings

• OffsetDrawbar

• RearWheelWeightSet

• RearAxleExtension(4in.or2in.)

• RearWorkLight

• RightHandStepwithHandrail(usedwithoutmid-mount valve.)

• HoodGuard

LV,1030HA,A5–19–07MAY96–1/1

ServiceEquipmentandTools

NOTE:Ordertoolsaccordingtoinformationgiveninthe U.S.SERVICEGARD Catalogorfromthe EuropeanMicroficheToolCatalog(MTC).Some toolsmaybeavailablefromalocalsupplier.

SERVICEGARDisatrademarkofDeere&Company

LiftingBracket ....................... JT01748

Installtoengineforremoval.

LiftingBracket JTG19

Installtoengineforremoval.

Specifications

ItemMeasurementSpecification

LargeFrontEngineMountCapTorque300N•m(225lb-ft) Screws

SmallFrontEngineMountCapTorque110N•m(80lb-ft) Screws

CenterControlConsoleCapScrewsTorque26N•m(19lb-ft)

JohnDeereEngineRepair—UseCTM8

Forcompleterepairinformationthecomponenttechnical manual(CTM)isalsorequired.Usethecomponent technicalmanualinconjunctionwiththismachinemanual.

1.Disconnectbattery.(SeeprocedureinSection40, Group10.)

2.Removeaircleaner.

3.Removeradiator.(SeeprocedureinGroup10.)

NOTE:Theapproximatecapacityoftransmissionis33L (8.7U.S.gal).

4.Draintransmission/hydraulicoil.

5.Removedashpanelsandhood.

6.Removemufflerandexhauststack.

NOTE:Closeallopeningsusingcapsandplugs.

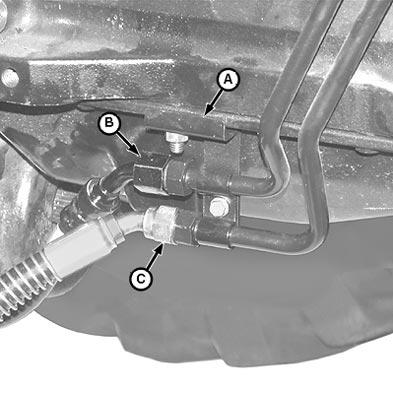

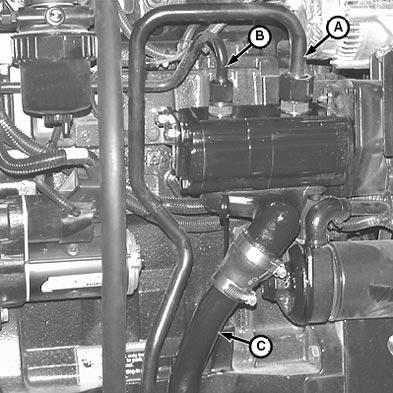

7.Markanddisconnecthydraulicsteeringhoses(Band C).

8.Removesteeringlinebracket(A)fromengine.

9.Disconnectsteeringreturnline(D).

A—SteeringLineBracket B—HydraulicSteeringHose C—HydraulicSteeringHose D—HydraulicSteeringReturnLine

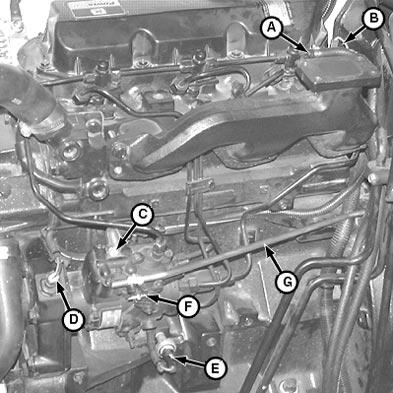

10.Removecotterpin(F)anddisconnectlinkagerod(G) fromfuelinjectionpump.

11.Markanddisconnectfuelreturnhose(A).Plugendof hose.

12.Disconnectelectricalconnectors(B—E),cutwireties andremovewiringharnessfromleft-sideof engine-to-centercontrolconsole.

A—FuelReturnHose

B—CoolantTemperatureSenderConnector

C—FuelInjectionPumpConnector

D—EngineSpeedSensorConnector

E—OilPressureSensorConnector

F—CotterPin

G—ThrottleLinkageRod

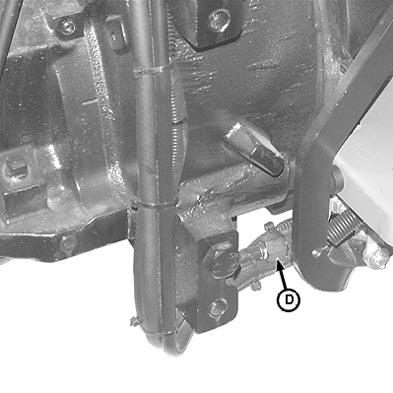

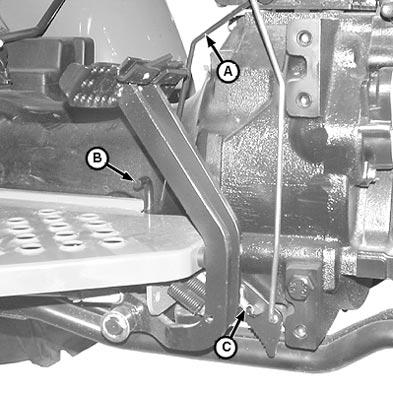

13.Disconnectthrottlelinkagerod(A)fromfootthrottle (B).

14.Disconnectparkbrakereturnspring(C).

A—FootThrottleLinkageRod

B—FootThrottle

C—ParkBrakeReturnSpring

15.Removehydrauliclines(A—C).

A—InletValveSupplyLine

B—SteeringValveSupplyLine

C—HydraulicPumpSupplyLine

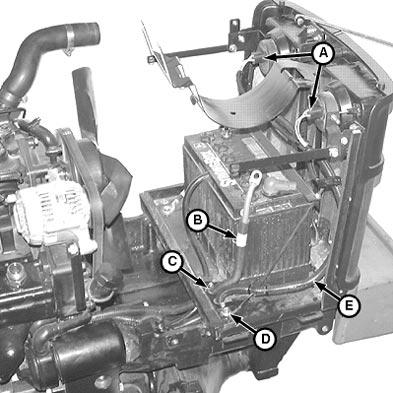

16.Removeplateandgasket(C).

17.Disconnectheadlightconnectors(A).

18.Disconnectgroundwiringconnector(D).

19.Pullcable(B)andwiringharness(E)intoenginebay compartment.

A—HeadlightConnector(2used)

B—Positive(+)BatteryCable C—PlateandGasket

D—ElectricalGroundWiringConnector E—WiringHarness

AG,OUO1008,224–19–12OCT99–4/9

AG,OUO1008,224–19–12OCT99–5/9