444J,544J,624JLoader OperationandTest

TECHNICALMANUAL

444J,544J,624JLoaderOperation andTest

10OCT06(ENGLISH)

Forcompleteserviceinformationalsosee:

444J,544J,624JLoaderRepairManual .... TM2136

444J,544J,624JLoaderOperator’s Manual OMT197190

AlternatorsandStartingMotors CTM77

POWERTECH 4.5L&6.8LDieselEngines

BaseEngine .......................... CTM104

TEAMMATE III1000,1200,and1400

SeriesInboardPlanetaryAxles .......... CTM150

POWERTECH 4.5Land6.8LDiesel EnginesLevel11ElectronicFuelSystem withDensoHPCR ..................... CTM220

SuperCaddyOilCleanupProcedure ...... CTM310

POWERTECH 4.5Land6.8LDiesel EnginesLevel12ElectronicFuelSystem withDE10Pump CTM331

120SeriesHydraulicCylinders .......... TM-H120A

125SeriesHydraulicCylinders .......... TM-H125A

185SeriesHydraulicCylinders .......... TM-H185A

SERVICEADVISOR SystemComputer Connection........................... T133991

DOWNLOAD SERVICE MANUAL

Introduction

Foreword

Thismanualiswrittenforanexperiencedtechnician. Essentialtoolsrequiredinperformingcertainservicework areidentifiedinthismanualandarerecommendedfor use.

Livewithsafety:Readthesafetymessagesinthe introductionofthismanualandthecautionspresented throughoutthetextofthemanual.

Thisisthesafety-alertsymbol.Whenyouseethis symbolonthemachineorinthismanual,bealerttothe potentialforpersonalinjury.

Technicalmanualsaredividedintwoparts:repairand operationandtests.Repairsectionstellhowtorepairthe components.Operationandtestssectionshelpyou identifythemajorityofroutinefailuresquickly.

Informationisorganizedingroupsforthevarious componentsrequiringserviceinstruction.Atthebeginning ofeachgrouparesummarylistingsofallapplicable essentialtools,serviceequipmentandtools,other materialsneededtodothejob,servicepartskits, specifications,weartolerances,andtorquevalues.

TechnicalManualsareconciseguidesforspecific machines.Theyareon-the-jobguidescontainingonlythe vitalinformationneededfordiagnosis,analysis,testing, andrepair.

Fundamentalserviceinformationisavailablefromother sourcescoveringbasictheoryofoperation,fundamentals oftroubleshooting,generalmaintenance,andbasictype offailuresandtheircauses.

TX,INTR,DU2141–19–22MAR97–1/1

SECTION9000—GeneralInformation Group01—SafetyInformation

SECTION9005—OperationalCheckoutProcedure Group10—OperationalCheckoutProcedure

SECTION9010—Engine Group05—TheoryofOperation Group15—DiagnosticInformation Group25—Tests

SECTION9015A—ElectricalSystem(S.N.—600915) Group05—SystemInformation Group10—SystemDiagrams Group15—Sub-SystemDiagnostics Group20—References

SECTION9015B—ElectricalSystem(S.N.600916— ) Group05—SystemInformation Group10—SystemDiagrams Group15—Sub-SystemDiagnostics Group20—References

SECTION9020—PowerTrain Group05—TheoryofOperation Group15—DiagnosticInformation

Group20—Adjustments Group25—Tests

SECTION9025—HydraulicSystem Group05—TheoryofOperation Group15—DiagnosticInformation Group20—Adjustments Group25—Test

SECTION9031—HeatingAndA/C Group05—TheoryOfOperation

Group15—DiagnosticInformation Group25—Tests

Allinformation,illustrationsandspecificationsinthismanualarebasedon thelatestinformationavailableatthetimeofpublication.Therightis reservedtomakechangesatanytimewithoutnotice.

Group01—SafetyInformation

RecognizeSafetyInformation

9000-01-1

FollowSafetyInstructions 9000-01-1

OperateOnlyIfQualified 9000-01-2

WearProtectiveEquipment 9000-01-2

AvoidUnauthorizedMachine

Modifications

9000-01-2

AddCabGuardingForSpecialUses 9000-01-3

InspectMachine ...................... 9000-01-3

StayClearofMovingParts .............. 9000-01-3

AvoidHigh-PressureOil 9000-01-4

BewareofExhaustFumes 9000-01-4

PreventFires 9000-01-5

PreventBatteryExplosions

9000-01-5

HandleChemicalProductsSafely 9000-01-6

DisposeofWasteProperly 9000-01-6

PrepareforEmergencies

9000-01-6

UseStepsandHandholdsCorrectly 9000-01-7

StartOnlyFromOperator’sSeat .......... 9000-01-7

UseandMaintainSeatBelt .............. 9000-01-7

PreventUnintendedMachineMovement 9000-01-8

AvoidWorkSiteHazards 9000-01-9

UseSpecialCareWhenOperating Loader 9000-01-10

KeepRidersOffMachine 9000-01-10

AvoidBackoverAccidents 9000-01-11

AvoidMachineTipOver 9000-01-11

OperatingonSlopes

9000-01-12

OperatingOrTravelingOnPublicRoads..9000-01-12

InspectandMaintainROPS ............ 9000-01-13

AddandOperateAttachmentsSafely ..... 9000-01-13

ParkAndPrepareForServiceSafely 9000-01-14

ServiceCoolingSystemSafely 9000-01-14

RemovePaintBeforeWeldingor Heating 9000-01-15

MakeWeldingRepairsSafely 9000-01-15

DriveMetalPinsSafely 9000-01-16

RecognizeSafetyInformation

Thisisthesafetyalertsymbol.Whenyouseethis symbolonyourmachineorinthismanual,bealert forthepotentialofpersonalinjury.

Followtheprecautionsandsafeoperatingpractices highlightedbythissymbol.

Asignalword—DANGER,WARNING,orCAUTION—is usedwiththesafetyalertsymbol.DANGERidentifiesthe mostserioushazards.

Onyourmachine,DANGERsignsareredincolor, WARNINGsignsareorange,andCAUTIONsignsare yellow.DANGERandWARNINGsignsarelocatednear specifichazards.GeneralprecautionsareonCAUTION labels.

TX03679,00016CC–19–01SEP06–1/1

FollowSafetyInstructions

Readthesafetymessagesinthismanualandonthe machine.Followthesewarningsandinstructionscarefully. Reviewthemfrequently.Keepsafetysignsingood condition.Replacemissingordamagedsafetysigns. ReplacementsafetysignsareavailablefromyourJohn Deeredealer.

Besurealloperatorsofthismachineunderstandevery safetymessage.Replaceoperator’smanualandsafety labelsimmediatelyifmissingordamaged.

TX03679,00016F9–19–13OCT03–1/1

OperateOnlyIfQualified

Donotoperatethismachineunlessyouhavereadthe operator’smanualcarefullyandyouhavebeen qualifiedbysupervisedtrainingandinstruction.

Familiarizeyourselfwiththejobsiteandyour surroundingsbeforeoperating.Tryallcontrolsand

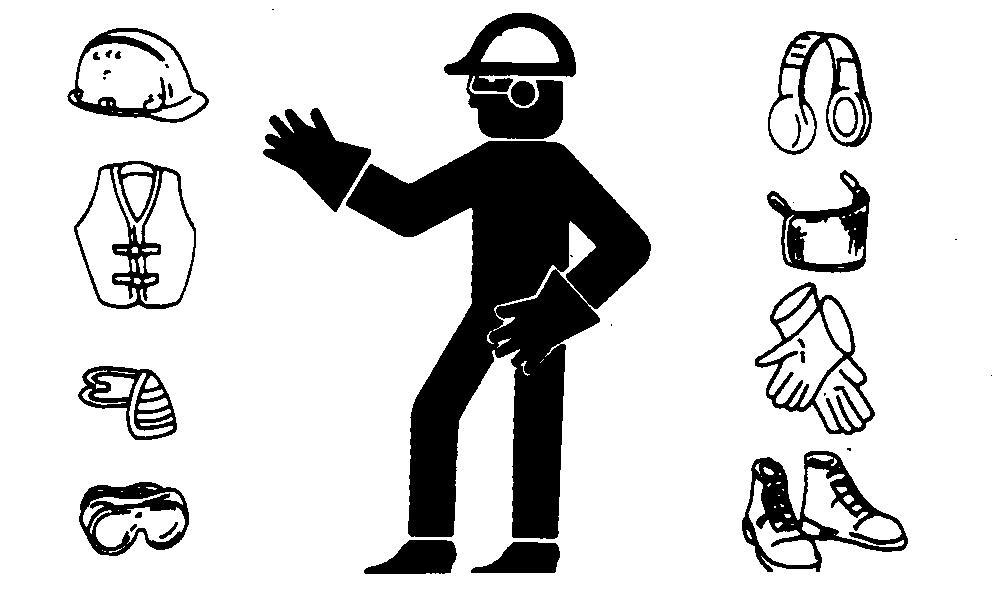

WearProtectiveEquipment

Guardagainstinjuryfromflyingpiecesofmetalordebris; weargogglesorsafetyglasses.

Wearclosefittingclothingandsafetyequipment appropriatetothejob.

Prolongedexposuretoloudnoisecancauseimpairment orlossofhearing.Wearsuitablehearingprotectionsuch asearmuffsorearplugstoprotectagainstobjectionableor uncomfortableloudnoises.

machinefunctionswiththemachineinanopenarea beforestartingtowork.

Knowandobserveallsafetyrulesthatmayapplyto yourworksituationandyourworksite.

TX03679,00016FA–19–01SEP06–1/1

TX03679,00016D0–19–01SEP06–1/1

AvoidUnauthorizedMachineModifications

JohnDeererecommendsusingonlygenuineJohn Deerereplacementpartstoensuremachine performance.NeversubstitutegenuineJohnDeere partswithalternatepartsnotintendedforthe applicationasthesecancreatehazardoussituationsor hazardousperformance.Non-JohnDeereParts,orany damageorfailuresresultingfromtheirusearenot coveredbyanyJohnDeerewarranty.

Modificationsofthismachine,oradditionof unapprovedproductsorattachments,mayaffect

machinestabilityorreliability,andmaycreateahazard fortheoperatororothersnearthemachine.The installerofanymodificationwhichmayaffectthe electroniccontrolsofthismachineisresponsiblefor establishingthatthemodificationdoesnotadversely affectthemachineoritsperformance.

Alwayscontactanauthorizeddealerbeforemaking machinemodificationsthatchangetheintendeduse, weightorbalanceofthemachine,orthatalter machinecontrols,performanceorreliability.

AM40430,00000A9–19–22APR05–1/1

SafetyInformation

AddCabGuardingForSpecialUses

Specialworksituationsormachineattachmentsmay createanenvironmentwithfallingorflyingobjects. Loadinglogs,usingforkattachments,oroperatingin wastemanagementapplicationsrequiresspecialwork tools.Addedcabguardingtoprotecttheoperatormay alsoberequired.

Useload-clampinggrapplestokeepbulkyloadsfrom fallingandaddspecialscreensorguardingwhenobjects maybedirectedtowardthecab.Contactyourauthorized dealerforinformationondevicesintendedtoprotectthe operatorfromfallingorflyingobjectsinspecialwork situations.

InspectMachine

Inspectmachinecarefullyeachdaybywalkingaroundit beforestarting.

Keepallguardsandshieldsingoodconditionand properlyinstalled.Fixdamageandreplacewornorbroken partsimmediately.Payspecialattentiontohydraulic hosesandelectricalwiring.

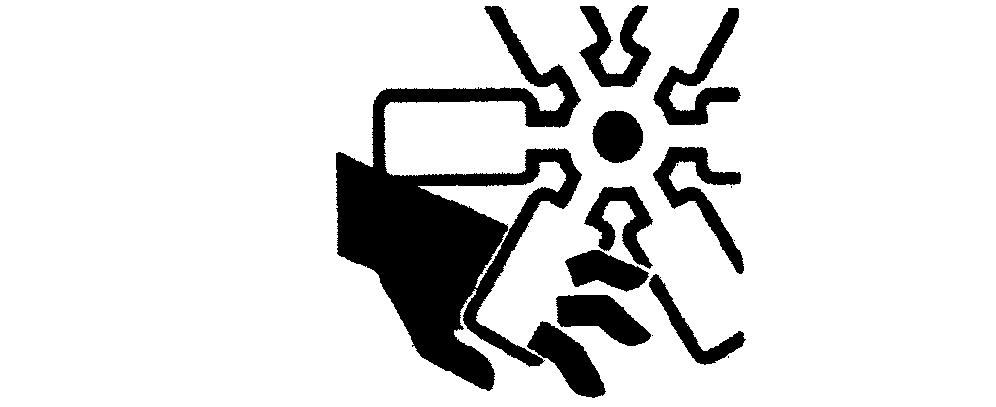

StayClearofMovingParts

Entanglementsinmovingpartscancauseseriousinjury.

Stopenginebeforeexamining,adjustingormaintaining anypartofmachinewithmovingparts.

Keepguardsandshieldsinplace.Replaceanyguardor shieldthathasbeenremovedforaccessassoonas serviceorrepairiscomplete.

TX03679,00017C6–19–01JUN01–1/1

TX03679,0001734–19–01SEP06–1/1

TX03679,00016D2–19–01SEP06–1/1

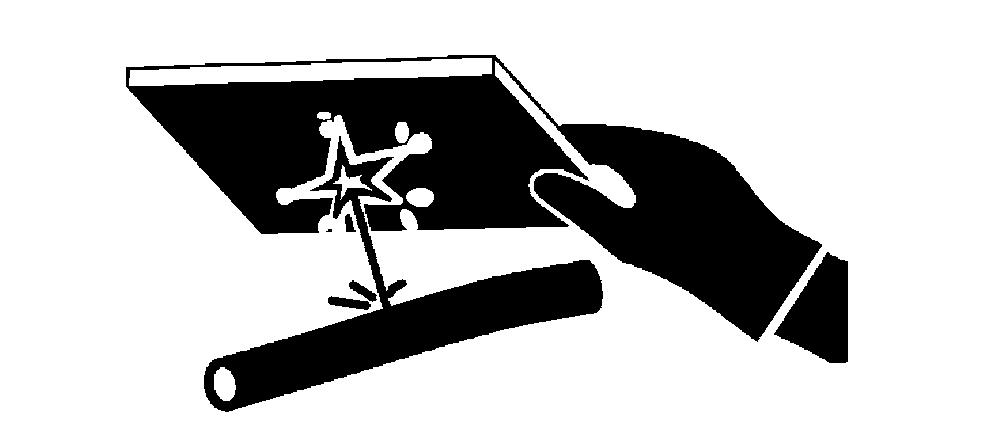

AvoidHigh-PressureOil

Thismachineusesahigh-pressurehydraulicsystem. Escapingoilunderpressurecanpenetratetheskin causingseriousinjury.

Neversearchforleakswithyourhands. Protecthands. Useapieceofcardboardtofindlocationofescapingoil. Stopengineandrelievepressurebeforedisconnecting linesorworkingonhydraulicsystem.

Ifhydraulicoilpenetratesyourskin,seeadoctor immediately.Injectedoilmustberemovedsurgically withinhoursorgangrenemayresult. Contacta knowledgeablemedicalsourceortheDeere&Company MedicalDepartmentinMoline,Illinois,U.S.A.

BewareofExhaustFumes

Preventasphyxiation.Engineexhaustfumescancause sicknessordeath.

Ifyoumustoperateinabuilding,provideadequate ventilation.Useanexhaustpipeextensiontoremovethe exhaustfumesoropendoorsandwindowstobring outsideairintothearea.

TX03679,00016D3–19–07SEP06–1/1

TX03679,00016D4–19–07SEP06–1/1

SafetyInformation

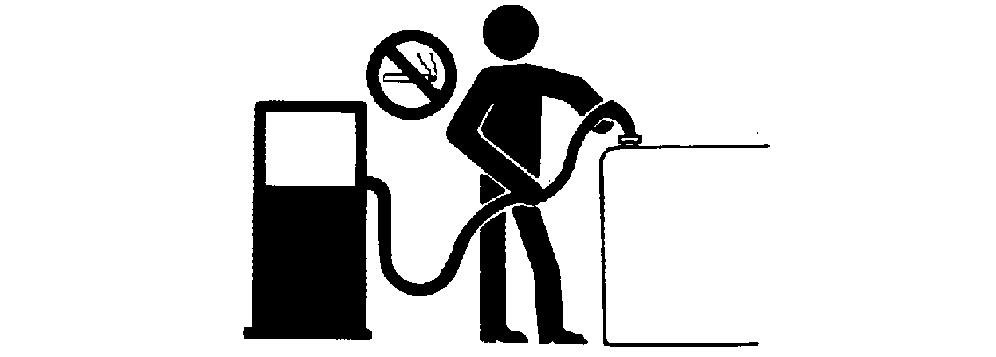

PreventFires

HandleFuelSafely: Storeflammablefluidsawayfrom firehazards.Neverrefuelmachinewhilesmokingorwhen nearsparksorflame.

CleanMachineRegularly: Keeptrash,debris,grease andoilfromaccumulatinginenginecompartment,around fuellines,hydrauliclinesandelectricalwiring.Neverstore oilyragsorflammablematerialsinsideamachine compartment.

MaintainHosesandWiring: Replacehydraulichoses immediatelyiftheybegintoleak,andcleanupanyoil spills.Examineelectricalwiringandconnectorsfrequently fordamage.

KeepAFireExtinguisherAvailable: Alwayskeepa multi-purposefireextinguisheronornearthemachine. Knowhowtouseextinguisherproperly.

PreventBatteryExplosions

Batterygascanexplode.Keepsparks,lightedmatches, andopenflameawayfromthetopofbattery.

Nevercheckbatterychargebyplacingametalobject acrosstheposts.Useavoltmeterorhydrometer.

Donotchargeafrozenbattery;itmayexplode.Warm batteryto16°C(60°F).

HandleChemicalProductsSafely

Exposuretohazardouschemicalscancauseserious injury.Undercertainconditions,lubricants,coolants, paintsandadhesivesusedwiththismachinemaybe hazardous.

Ifuncertainaboutsafehandlingoruseofthesechemical products,contactyourauthorizeddealerforaMaterial SafetyDataSheet(MSDS)orgotointernetwebsite http://www.jdmsds.com.TheMSDSdescribesphysical andhealthhazards,safeuseprocedures,andemergency responsetechniquesforchemicalsubstances.Follow MSDSrecommendationstohandlechemicalproducts safely.

DisposeofWasteProperly

Improperdisposalofwastecanthreatentheenvironment. Fuel,oils,coolants,filtersandbatteriesusedwiththis machinemaybeharmfulifnotdisposedofproperly.

Neverpourwasteontotheground,downadrain,orinto anywatersource.

Airconditioningrefrigerantscandamagetheatmosphere. Governmentregulationsmayrequireusingacertified servicecentertorecoverandrecycleusedrefrigerants.

Ifuncertainaboutthesafedisposalofwaste,contactyour localenvironmentalorrecyclingcenteroryourdealerfor moreinformation.

PrepareforEmergencies

Bepreparedifanemergencyoccursorafirestarts.

Keepafirstaidkitandfireextinguisherhandy.

Keepemergencynumbersfordoctors,ambulanceservice, hospital,andfiredepartmentnearyourtelephone.

TX03679,00016D7–19–07SEP06–1/1

TX03679,0001733–19–07FEB06–1/1

TX03679,000174B–19–14SEP00–1/1

SafetyInformation

UseStepsandHandholdsCorrectly

Preventfallsbyfacingthemachinewhenyougetonand off.Maintain3-pointcontactwithstepsandhandrails. Neverusemachinecontrolsashandholds.

Useextracarewhenmud,snow,ormoisturepresent slipperyconditions.Keepstepscleanandfreeofgrease oroil.Neverjumpwhenexitingmachine.Nevermountor dismountamovingmachine.

StartOnlyFromOperator’sSeat

Avoidunexpectedmachinemovement.Startengineonly whilesittinginoperator’sseat.Ensureallcontrolsand workingtoolsareinproperpositionforaparkedmachine.

Neverattempttostartenginefromtheground.Donot attempttostartenginebyshortingacrossthestarter solenoidterminals.

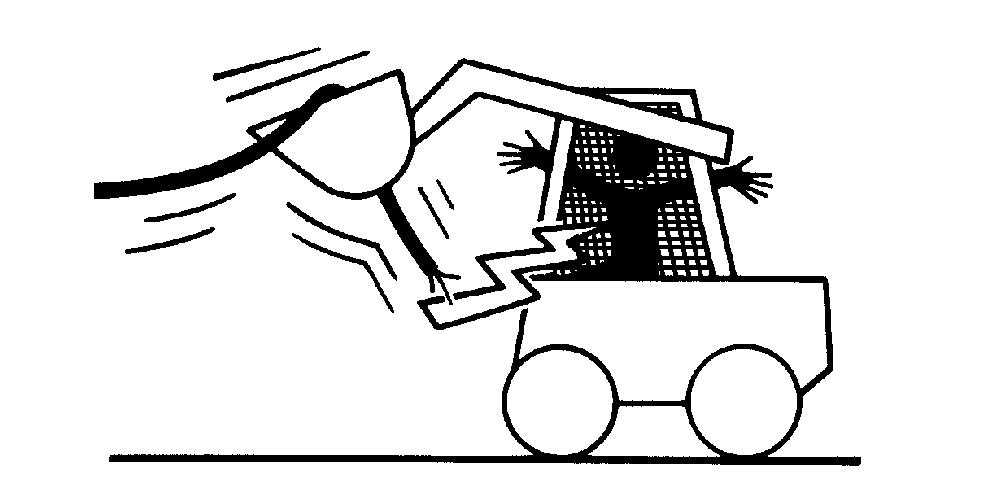

UseandMaintainSeatBelt

Useseatbeltwhenoperatingmachine.Rememberto fastenseatbeltwhenloadingandunloadingfromtrucks andduringotheruses.

Examineseatbeltfrequently.Besurewebbingisnotcut ortorn.Replaceseatbeltimmediatelyifanypartis damagedordoesnotfunctionproperly.

Thecompleteseatbeltassemblyshouldbereplaced everythreeyears,regardlessofappearance.

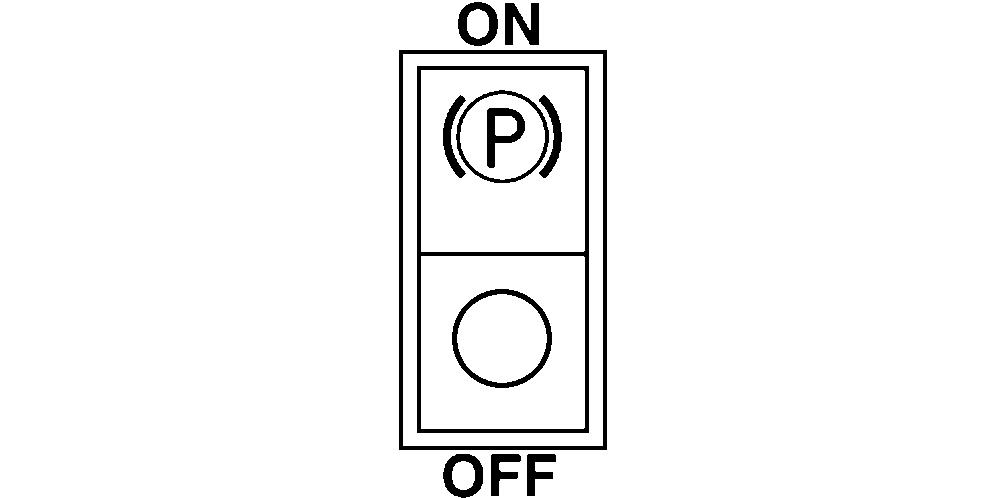

PreventUnintendedMachineMovement

Whenco-workersarepresent,disablehydraulics. Lowerallequipmenttothegroundduringwork interruptions.Locktransmissioncontrolinneutral,engage parkbrakeandstopenginebeforeallowinganyoneto approachthemachine.

Followthesesameprecautionsbeforestandingup, leavingtheoperator’sseat,orexitingthemachine.

TX03679,00017C7–19–28OCT02–1/1

AvoidWorkSiteHazards

Avoidcontactwithgaslines,buriedcablesandwater lines.Callutilitylinelocationservicestoidentifyall undergroundutilitiesbeforestartingwork.

Prepareworksiteproperly. Avoidoperatingnear structuresorobjectsthatcouldfallontothemachine. Clearawaydebristhatcouldmoveunexpectedlyifrun over.

Avoidboomorattachmentcontactwithoverhead obstaclesoroverheadelectricallines. Nevermove machinecloserthan3m(10ft)plustwicetheline insulatorlengthtooverheadwires.

Keepbystandersclearatalltimes. Usebarricadesora signalpersontokeepvehiclesandpedestriansaway.Use asignalpersonifmovingmachineincongestedareasor wherevisibilityisrestricted.Alwayskeepsignalpersonin view.Coordinatehandsignalsbeforestartingmachine.

Operateonlyonsolidfooting withstrengthsufficientto supportmachine.Beespeciallyalertworkingnear embankmentsorexcavations.

Avoidworkingunderover-hangingembankmentsor stockpiles thatcouldcollapseunderoronmachine.

Reducemachinespeed whenoperatingwithtoolonor neargroundwhenobstaclesmaybehidden(e.g.,during snowremovalorclearingmud,dirt,etc.).Athighspeeds hittingobstacles(rocks,unevenconcreteormanholes) cancauseasuddenstop.Alwayswearyourseatbelt.