540G,640G,740G, Skidderand 548G,648G,748G

GrappleSkidder (S.N.—565684)Repair

TECHNICALMANUAL

540G,640G,740G,Skidderand 548G,648G,748GGrappleSkidder (S.N.—565684)Repair

TM160003AUG98(ENGLISH)

Forcompleteserviceinformationalsosee:

540G,640G,740GSkidderand548G,648G, 748GGrappleSkidder(S.N.—565684)

OperationandTest

TM1599

4045,6059,6068Engine CTM8 6076Engine CTM42

StartingMotorsandAlternators .......... CTM77

JohnDeerePowerTech4.5Land6.8L Engine .............................. CTM104

JohnDeerePowerTech8.1LEngine ..... CTM86 4000SeriesWinch ..................... CTM25 6000SeriesWinch ..................... CTM41

TeamMateIIAxles ..................... CTM43

Introduction

Foreword

Thismanualiswrittenforanexperiencedtechnician. Essentialtoolsrequiredinperformingcertainservice workareidentifiedinthismanualandare recommendedforuse.

Livewithsafety:Readthesafetymessagesinthe introductionofthismanualandthecautionspresented throughoutthetextofthemanual.

Thisisthesafety-alertsymbol.Whenyouseethis symbolonthemachineorinthismanual,bealertto thepotentialforpersonalinjury.

Technicalmanualsaredividedintwoparts:repairand operationandtests.Repairsectionstellhowtorepair thecomponents.Operationandtestssectionshelpyou identifythemajorityofroutinefailuresquickly.

Informationisorganizedingroupsforthevarious componentsrequiringserviceinstruction.Atthe beginningofeachgrouparesummarylistingsofall applicableessentialtools,serviceequipmentandtools, othermaterialsneededtodothejob,servicepartskits, specifications,weartolerances,andtorquevalues.

TechnicalManualsareconciseguidesforspecific machines.Theyareon-the-jobguidescontainingonly thevitalinformationneededfordiagnosis,analysis, testing,andrepair.

Fundamentalserviceinformationisavailablefrom othersourcescoveringbasictheoryofoperation, fundamentalsoftroubleshooting,generalmaintenance, andbasictypeoffailuresandtheircauses.

DX,TMIFC–19–22MAY92–1/1

SECTION16—ElectricalSystem

SECTION00—GeneralInformationSECTION11—ParkBrake Group1111—ActiveElements Group0001—SafetyInformation Group0002—GeneralSpecificationsGroup1160—HydraulicSystem Group0003—TorqueValues Group0004—FuelsandLubricants

01 Group1671—Batteries,SupportandCables Group1672—Alternator,RegulatorandCharging

SECTION01—Wheels SystemWiring Group0110—PoweredWheelsandFastenings Group1673—LightingSystem Group1674—WiringHarnessandSwitches

SECTION02—AxlesandSuspensionSystem Group1676—InstrumentsandIndicators Group0200—RemovalandInstallation Group1677—MotorsandActuators Group0225—InputDriveShaftsandU-Joints Group0260—HydraulicSystem

SECTION17—Frame,Chassis,orSupporting Structures

SECTION03—Transmission Group1740—FrameInstallation

Group0300—RemovalandInstallation Group1746—FrameBottomGuards Group0315—ControlLinkage Group0325—InputDriveShaftsandU-Joints

SECTION18—Operator’sStation Group0350—Gears,ShaftsandBearings Group1800—RemovalandInstallation Group0360—HydraulicSystem Group1810—OperatorEnclosure Group1821—SeatandSeatBelt

SECTION04—Engine Group1830—HeatingandAirConditioning Group0400—RemovalandInstallation

SECTION19—SheetMetalandStyling

SECTION05—EngineAuxiliarySystems Group1910—HoodorEngineEnclosure

Group0505—ColdWeatherStartingAids Group1921—GrilleandGrilleHousing Group0510—CoolingSystems Group0515—SpeedControls

SECTION20—Safety,Convenienceand Group0520—IntakeSystem Miscellaneous Group0530—ExternalExhaustSystem Group2003—FireExtinguisher Group0560—ExternalFuelSupplySystem Group2004—HornandWarningDevices

SECTION07—DamperDrive

SECTION21—MainHydraulicSystem Group0752—Elements Group2160—HydraulicSystem

SECTION09—SteeringSystem

SECTION30—Winch

Group0930—SecondarySteering Group3000—RemovalandInstallation Group0960—HydraulicSystem Group3015—ControlsLinkage Group3025—InputDriveShaftsandU-Joints

SECTION10—ServiceBrakes Group1011—ActiveElements

SECTION32—Bulldozers(Stackingand Group1015—ControlsLinkage

Group1060—HydraulicSystem

Allinformation,illustrationsandspecificationsinthismanualarebasedon thelatestinformationavailableatthetimeofpublication.Therightis reservedtomakechangesatanytimewithoutnotice.

DisposeofWasteProperly 00-0001-10 Specifications

LiveWithSafety 00-0001-10

Group0002—GeneralSpecifications

540GSkidder 00-0002-2

HardwareTorqueSpecifications

00-0003-1

00-0003-1

KeepingROPSInstalledProperly ......... 00-0003-1

TightenUpperFramePivotPin 00-0003-2

540GSkidderEngineandSystem Values

MetricBoltandCapScrewTorque

00-0003-3 Specifications 00-0002-6

UnifiedInchBoltandCapScrewTorque

540GSkidderOtherInformation 00-0002-9 Values 00-0003-4 Winch—4000Series 00-0002-10

AdditionalMetricCapScrewTorque

540GSkidderCapacities 00-0002-12 Values 00-0003-5

548GGrappleSkidder

SingleFunctionGrappleSpecifications .... 00-0002-17

ServiceRecommendationsfor37° Flare

548GGrappleSkidderEngineandSystem and30° ConeSeatConnectors 00-0003-7 Specifications...................... 00-0002-18

Winch—4000Series 00-0002-23

ServiceRecommendationsforO-Ring

ServiceRecommendationsforFlatFace

548GGrappleSkidderCapacities 00-0002-25 O-RingSealFittings 00-0003-10

640GSkidder 00-0002-26

ServiceRecommendationsforMetric

640GSkidderEngineandSystem Specifications 00-0002-30SeriesFourBoltFlangeFitting 00-0003-11

640GSkidderOtherInformation 00-0002-33

Winch—4000Series .................. 00-0002-34 Continuedonnextpage

ServiceRecommendationsforInchSeries FourBoltFlangeFittings .............

Group0004—FuelsandLubricants

Specifications

DieselFuel

00-0003-12

00-0004-1

00-0004-1

LowSulfurDieselFuelConditioner 00-0004-2

HandlingandStoringDieselFuel 00-0004-2

DoNotUseGalvanizedContainers 00-0004-3

FuelTank 00-0004-3

DieselEngineOil

TransmissionHydraulicSystem,Park Brake,Differential,HandPumpandWinch

00-0004-4

Oils ..............................

00-0004-5

Grease 00-0004-6

LubricantStorage

00-0004-6

AlternativeandSyntheticLubricants 00-0004-7

MixingofLubricants

DieselEngineCoolant

00-0004-7

00-0004-8

HandleFluidsSafely—AvoidFires

Whenyouworkaroundfuel,donotsmokeorworknear heatersorotherfirehazards.

Storeflammablefluidsawayfromfirehazards.Donot incinerateorpuncturepressurizedcontainers.

Makesuremachineiscleanoftrash,grease,anddebris.

Donotstoreoilyrags;theycanigniteandburn spontaneously.

PreventBatteryExplosions

Keepsparks,lightedmatches,andopenflameawayfrom thetopofbattery.Batterygascanexplode.

Nevercheckbatterychargebyplacingametalobject acrosstheposts.Useavoltmeterorhydrometer.

Donotchargeafrozenbattery;itmayexplode.Warm batteryto16°C(60°F).

ChargeBattery—Minimum Temperature16

PrepareforEmergencies

Bepreparedifafirestarts. Keepafirstaidkitandfireextinguisherhandy.

Keepemergencynumbersfordoctors,ambulanceservice, hospital,andfiredepartmentnearyourtelephone.

PreventAcidBurns

Sulfuricacidinbatteryelectrolyteispoisonous.Itisstrong enoughtoburnskin,eatholesinclothing,andcause blindnessifsplashedintoeyes.

Avoidthehazardby:

1.Fillingbatteriesinawell-ventilatedarea.

2.Wearingeyeprotectionandrubbergloves.

3.Avoidingbreathingfumeswhenelectrolyteisadded.

4.Avoidingspillingordrippingelectrolyte.

5.Useproperjumpstartprocedure.

Ifyouspillacidonyourself:

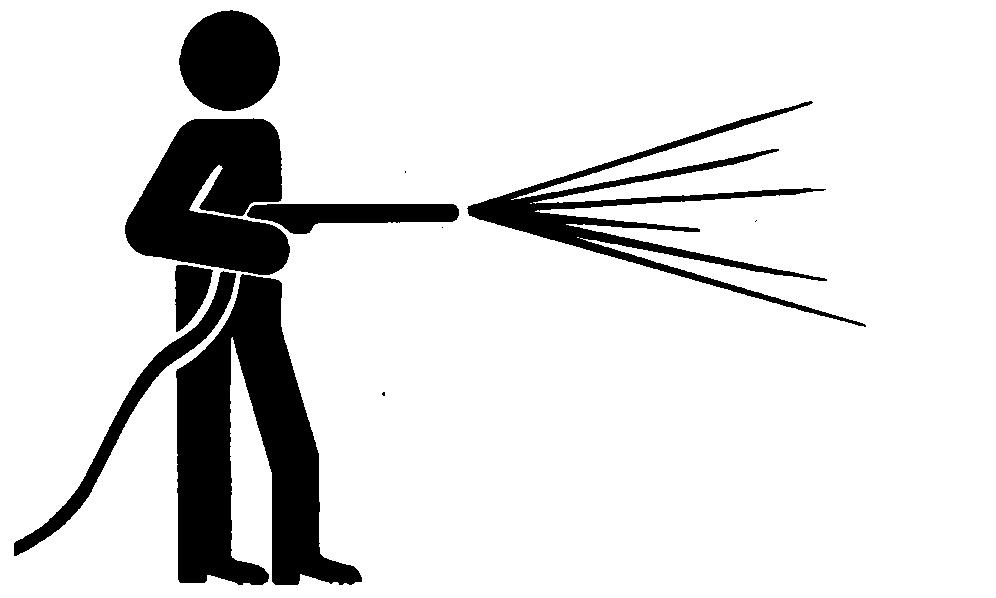

1.Flushyourskinwithwater.

2.Applybakingsodaorlimetohelpneutralizetheacid.

3.Flushyoureyeswithwaterfor15—30minutes.Get medicalattentionimmediately.

Ifacidisswallowed:

1.Donotinducevomiting.

2.Drinklargeamountsofwaterormilk,butdonot exceed2L(2 quarts).

3.Getmedicalattentionimmediately.

DX,POISON–19–21APR93–1/1

SafetyInformation

HandleChemicalProductsSafely

Directexposuretohazardouschemicalscancause seriousinjury.Potentiallyhazardouschemicalsusedwith yourmachineincludesuchitemsaslubricants,coolants, paints,andadhesives.

AMaterialSafetyDataSheet(MSDS)providesspecific detailsonchemicalproducts:physicalandhealthhazards, safetyprocedures,andemergencyresponsetechniques.

ChecktheMSDSbeforeyoustartanyjobusinga hazardouschemical.Thatwayyouwillknowexactlywhat therisksareandhowtodothejobsafely.Thenfollow proceduresandrecommendedequipment.

SeeyourauthorizeddealerforMSDS’sonchemical productsusedwithyourmachine.

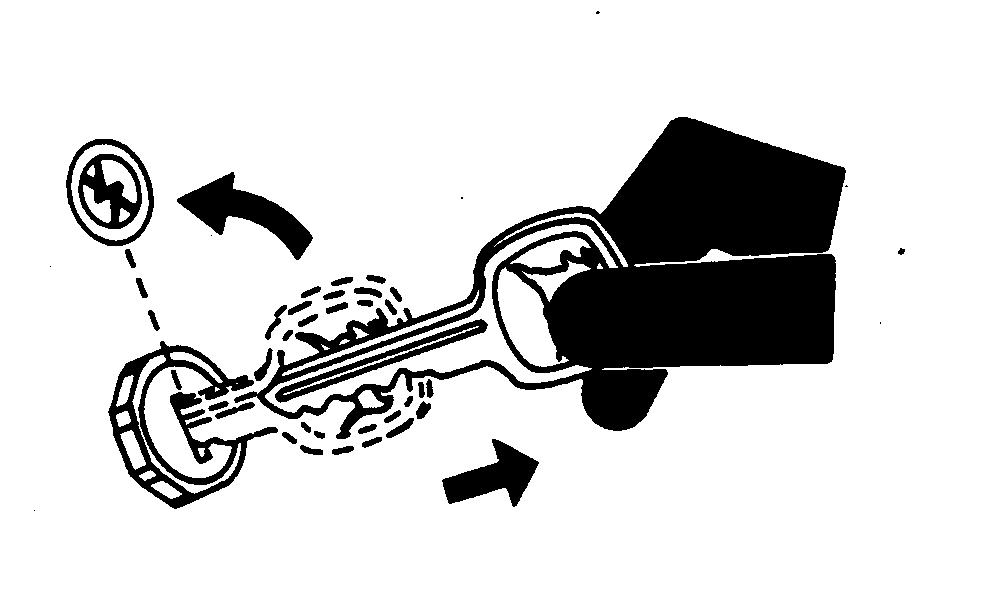

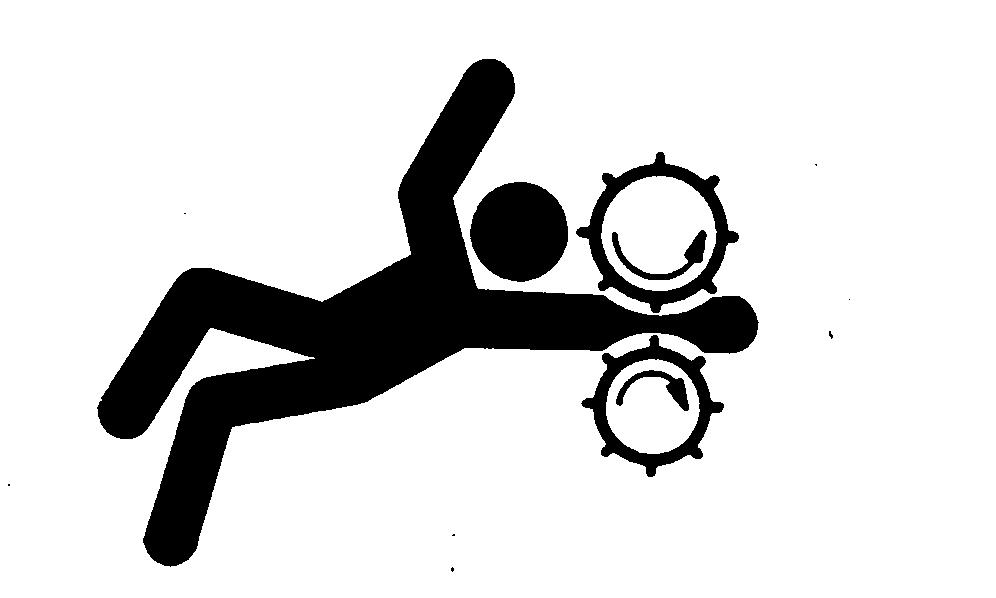

AvoidHigh-PressureFluids

Escapingfluidunderpressurecanpenetratetheskin causingseriousinjury.

Avoidthehazardbyrelievingpressurebefore disconnectinghydraulicorotherlines.Tightenall connectionsbeforeapplyingpressure.

Searchforleakswithapieceofcardboard.Protecthands andbodyfromhighpressurefluids.

Ifanaccidentoccurs,seeadoctorimmediately.Anyfluid injectedintotheskinmustbesurgicallyremovedwithina fewhoursorgangrenemayresult.Doctorsunfamiliarwith thistypeofinjuryshouldreferenceaknowledgeable medicalsource.SuchinformationisavailablefromDeere &CompanyMedicalDepartmentinMoline,Illinois,U.S.A.

ParkMachineSafely

Beforeworkingonthemachine:

• Lowerallequipmenttotheground.

• Stoptheengineandremovethekey.

• Disconnectthebatterygroundstrap.

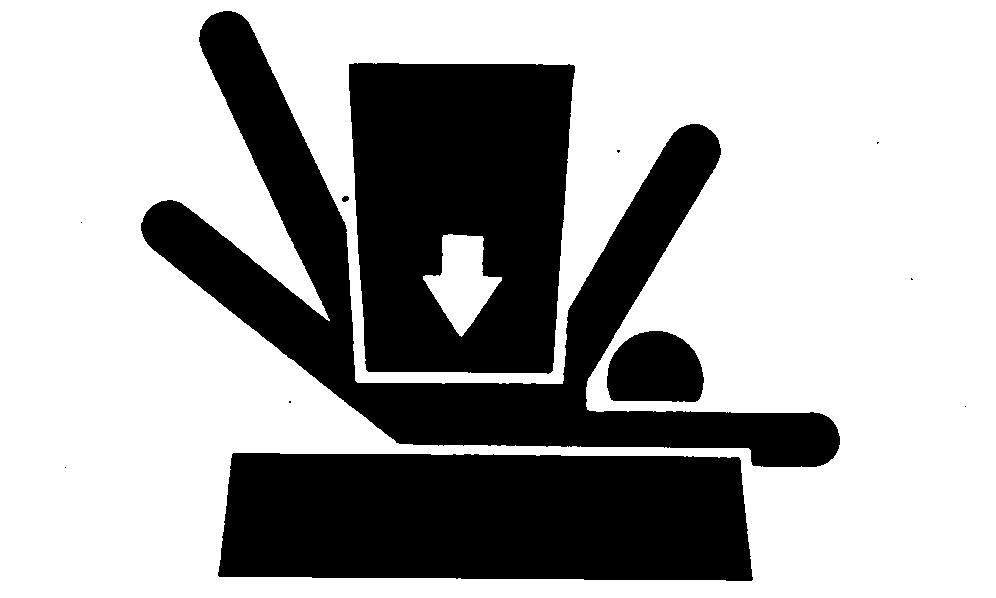

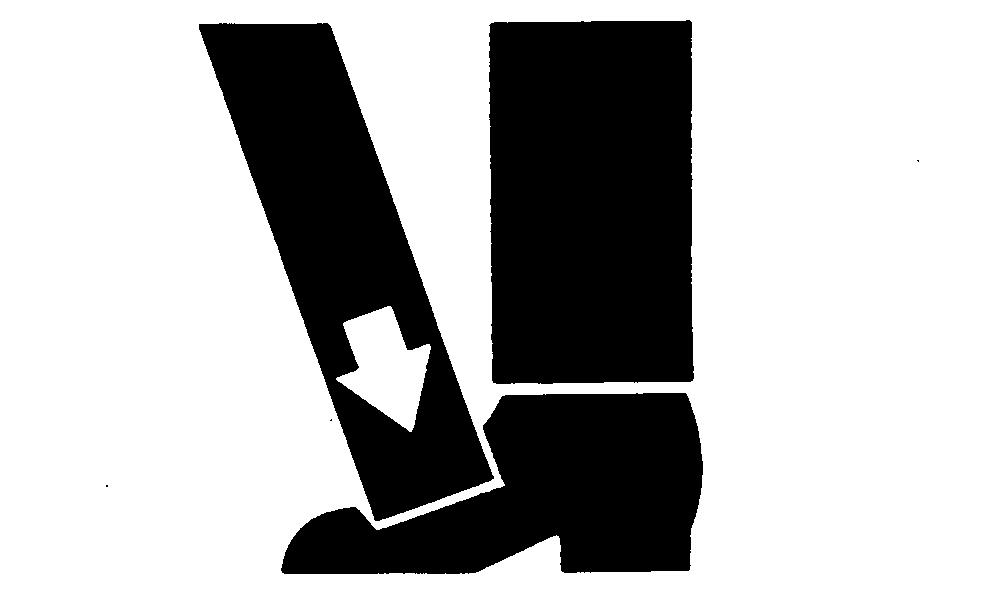

SupportMachineProperly

Alwayslowertheattachmentorimplementtotheground beforeyouworkonthemachine.Ifyoumustworkona liftedmachineorattachment,securelysupportthe machineorattachment.

Donotsupportthemachineoncinderblocks,hollowtiles, orpropsthatmaycrumbleundercontinuousload.Donot workunderamachinethatissupportedsolelybyajack. Followrecommendedproceduresinthismanual.

• Hanga"DONOTOPERATE"taginoperatorstation. DX,LOWER–19–04JUN90–1/1

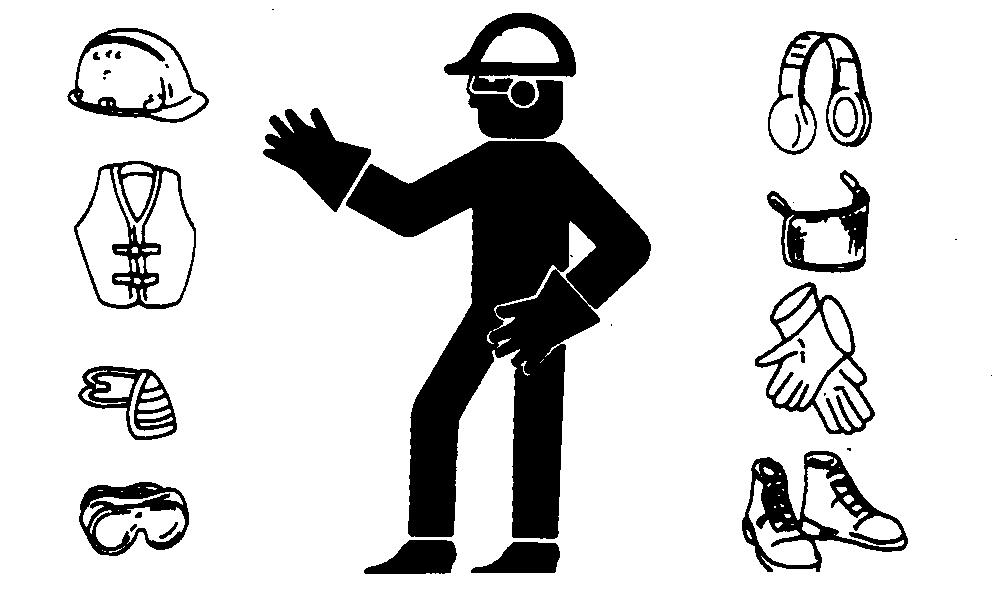

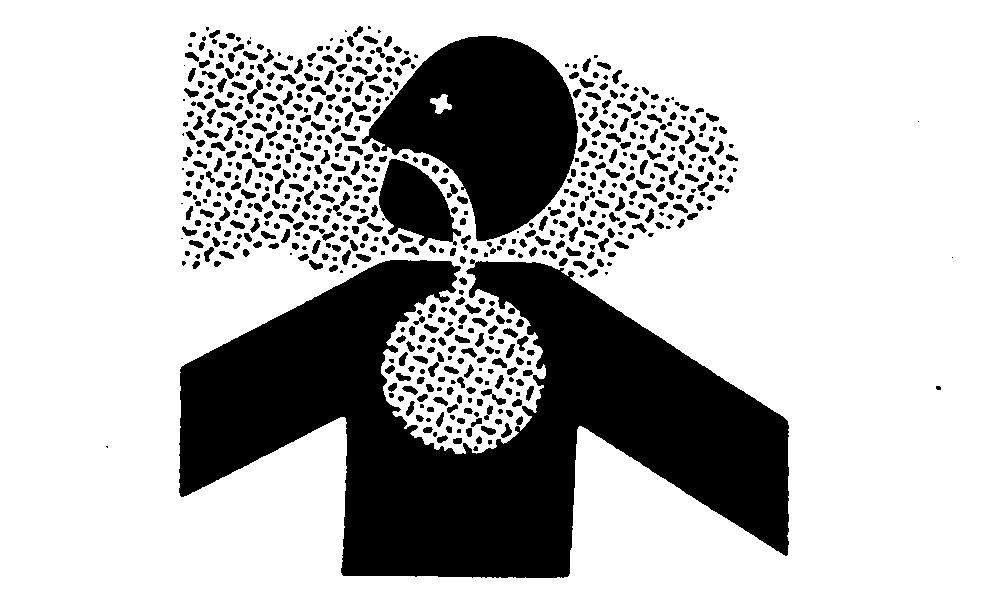

WearProtectiveClothing

Wearclosefittingclothingandsafetyequipment appropriatetothejob.

Prolongedexposuretoloudnoisecancauseimpairment orlossofhearing.

Wearasuitablehearingprotectivedevicesuchas earmuffsorearplugstoprotectagainstobjectionableor uncomfortableloudnoises.

Operatingequipmentsafelyrequiresthefullattentionof theoperator.Donotwearradioormusicheadphones whileoperatingmachine.

SafetyInformation

WorkinCleanArea

Beforestartingajob:

• Cleanworkareaandmachine.

• Makesureyouhaveallnecessarytoolstodoyourjob.

• Havetherightpartsonhand.

• Readallinstructionsthoroughly;donotattempt shortcuts.

ServiceMachinesSafely

Tielonghairbehindyourhead.Donotwearanecktie, scarf,looseclothing,ornecklacewhenyouworknear machinetoolsormovingparts.Iftheseitemsweretoget caught,severeinjurycouldresult.

Removeringsandotherjewelrytopreventelectrical shortsandentanglementinmovingparts.

WorkinVentilatedArea

Engineexhaustfumescancausesicknessordeath.Ifitis necessarytorunanengineinanenclosedarea,remove theexhaustfumesfromtheareawithanexhaustpipe extension.

Ifyoudonothaveanexhaustpipeextension,openthe doorsandgetoutsideairintothearea.

IlluminateWorkAreaSafely

Illuminateyourworkareaadequatelybutsafely.Usea portablesafetylightforworkinginsideorunderthe machine.Makesurethebulbisenclosedbyawirecage. Thehotfilamentofanaccidentallybrokenbulbcanignite spilledfueloroil.

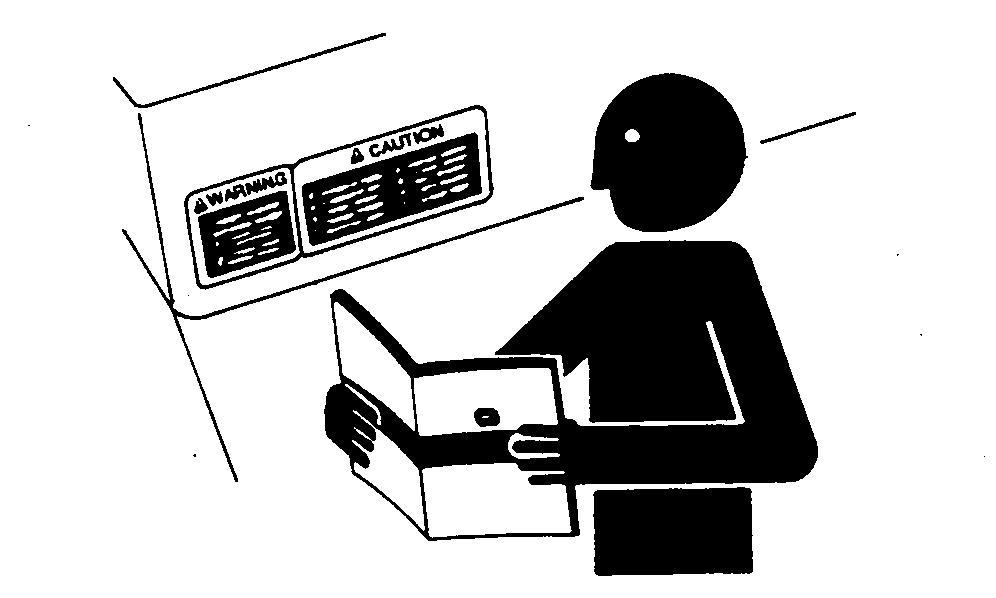

ReplaceSafetySigns

Replacemissingordamagedsafetysigns.Seethe machineoperator’smanualforcorrectsafetysign placement.

UseProperLiftingEquipment

Liftingheavycomponentsincorrectlycancausesevere injuryormachinedamage.

Followrecommendedprocedureforremovaland installationofcomponentsinthemanual.

RemovePaintBeforeWeldingorHeating

Avoidpotentiallytoxicfumesanddust.

Hazardousfumescanbegeneratedwhenpaintisheated bywelding,soldering,orusingatorch.

Doallworkoutsideorinawellventilatedarea.Disposeof paintandsolventproperly.

Removepaintbeforeweldingorheating:

• Ifyousandorgrindpaint,avoidbreathingthedust. Wearanapprovedrespirator.

• Ifyouusesolventorpaintstripper,removestripperwith soapandwaterbeforewelding.Removesolventor paintstrippercontainersandotherflammablematerial fromarea.Allowfumestodisperseatleast15minutes beforeweldingorheating.

AvoidHeatingNearPressurizedFluidLines

KeepROPSInstalledProperly

Makecertainallpartsarereinstalledcorrectlyifthe roll-overprotectivestructure(ROPS)isloosenedor removedforanyreason.Tightenmountingboltstoproper torque.

TheprotectionofferedbyROPSwillbeimpairedifROPS issubjectedtostructuraldamage,isinvolvedinan overturnincident,orisinanywayalteredbywelding, bending,drilling,orcutting.AdamagedROPSshouldbe replaced,notreused.

Flammablespraycanbegeneratedbyheatingnear pressurizedfluidlines,resultinginsevereburnsto yourselfandbystanders.Donotheatbywelding, soldering,orusingatorchnearpressurizedfluidlinesor otherflammablematerials.Pressurizedlinescanbe accidentallycutwhenheatgoesbeyondtheimmediate flamearea. DX,ROPS3–19–03MAR93–1/1

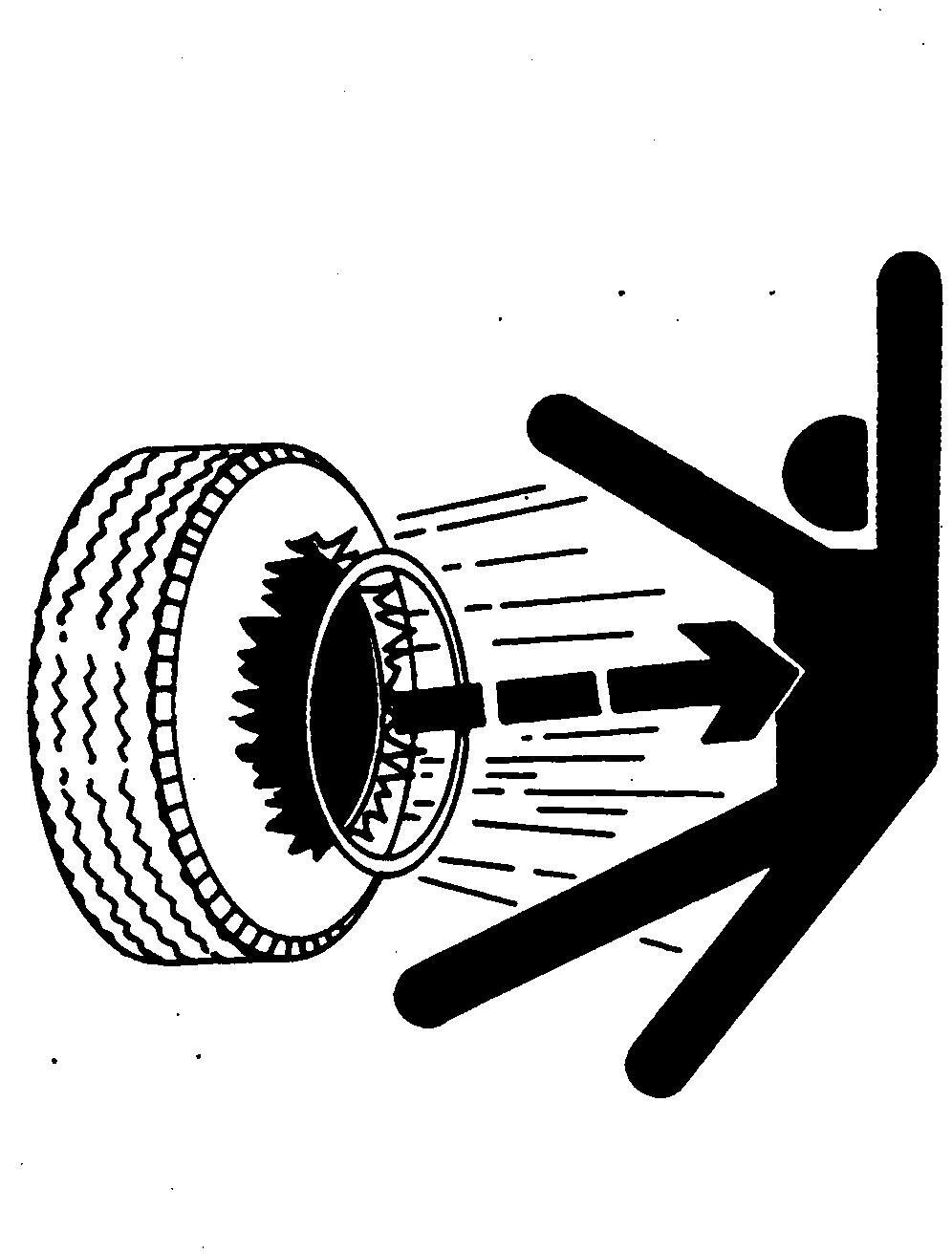

ServiceTiresSafely

Explosiveseparationofatireandrimpartscancause seriousinjuryordeath.

Donotattempttomountatireunlessyouhavetheproper equipmentandexperiencetoperformthejob.

Alwaysmaintainthecorrecttirepressure.Donotinflate thetiresabovetherecommendedpressure.Neverweldor heatawheelandtireassembly.Theheatcancausean increaseinairpressureresultinginatireexplosion. Weldingcanstructurallyweakenordeformthewheel.

Wheninflatingtires,useaclip-onchuckandextension hoselongenoughtoallowyoutostandtoonesideand NOTinfrontoforoverthetireassembly.Useasafety cageifavailable.

Checkwheelsforlowpressure,cuts,bubbles,damaged rimsormissinglugboltsandnuts.

AvoidHarmfulAsbestosDust

Avoidbreathingdustthatmaybegeneratedwhen handlingcomponentscontainingasbestosfibers.Inhaled asbestosfibersmaycauselungcancer.

Componentsinproductsthatmaycontainasbestosfibers arebrakepads,brakebandandliningassemblies,clutch plates,andsomegaskets.Theasbestosusedinthese componentsisusuallyfoundinaresinorsealedinsome way.Normalhandlingisnothazardousaslongas airbornedustcontainingasbestosisnotgenerated.

Avoidcreatingdust.Neverusecompressedairfor cleaning.Avoidbrushingorgrindingmaterialcontaining asbestos.Whenservicing,wearanapprovedrespirator.A specialvacuumcleanerisrecommendedtoclean asbestos.Ifnotavailable,applyamistofoilorwateron thematerialcontainingasbestos.

Keepbystandersawayfromthearea.

SafetyInformation

PracticeSafeMaintenance

Understandserviceprocedurebeforedoingwork.Keep areacleananddry.

Neverlubricate,service,oradjustmachinewhileitis moving.Keephands,feet,andclothingfrom power-drivenparts.Disengageallpowerandoperate controlstorelievepressure.Lowerequipmenttothe ground.Stoptheengine.Removethekey.Allowmachine tocool.

Securelysupportanymachineelementsthatmustbe raisedforservicework.

Keepallpartsingoodconditionandproperlyinstalled.Fix damageimmediately.Replacewornorbrokenparts. Removeanybuildupofgrease,oil,ordebris.

Disconnectbatterygroundcable(—)beforemaking adjustmentsonelectricalsystemsorweldingonmachine.

DX,SERV–19–03MAR93–1/1

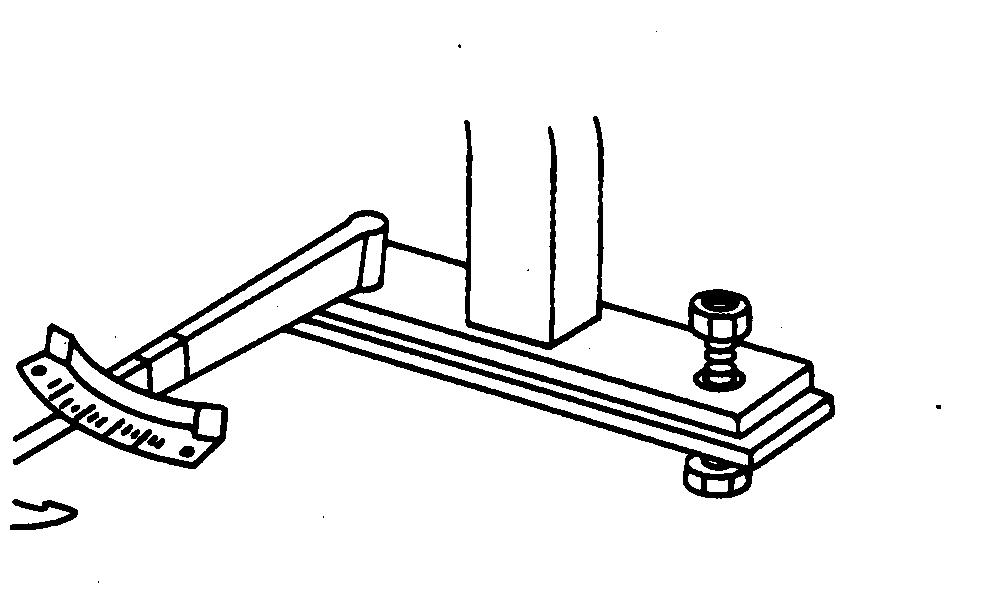

UseProperTools

Usetoolsappropriatetothework.Makeshifttoolsand procedurescancreatesafetyhazards.

Usepowertoolsonlytoloosenthreadedpartsand fasteners.

Forlooseningandtighteninghardware,usethecorrect sizetools.DONOTuseU.S.measurementtoolson metricfasteners.Avoidbodilyinjurycausedbyslipping wrenches.

UseonlyservicepartsmeetingJohnDeerespecifications.

DX,REPAIR–19–04JUN90–1/1

DisposeofWasteProperly

Improperlydisposingofwastecanthreatenthe environmentandecology.Potentiallyharmfulwasteused withyourmachineincludesuchitemsasoil,fuel,coolant, brakefluid,filters,andbatteries.

Useleakproofcontainerswhendrainingfluids.Donotuse foodorbeveragecontainersthatmaymisleadsomeone intodrinkingfromthem.

Donotpourwasteontotheground,downadrain,orinto anywatersource.

Airconditioningrefrigerantsescapingintotheaircan damagetheEarth’satmosphere.Governmentregulations mayrequireacertifiedairconditioningservicecenterto recoverandrecycleusedairconditioningrefrigerants.

Inquireontheproperwaytorecycleordisposeofwaste fromyourlocalenvironmentalorrecyclingcenter,orfrom yourauthorizeddealer.

LiveWithSafety

Beforereturningmachinetocustomer,makesure machineisfunctioningproperly,especiallythesafety systems.Installallguardsandshields.

TX,05,DH2502–19–26AUG92–1/1

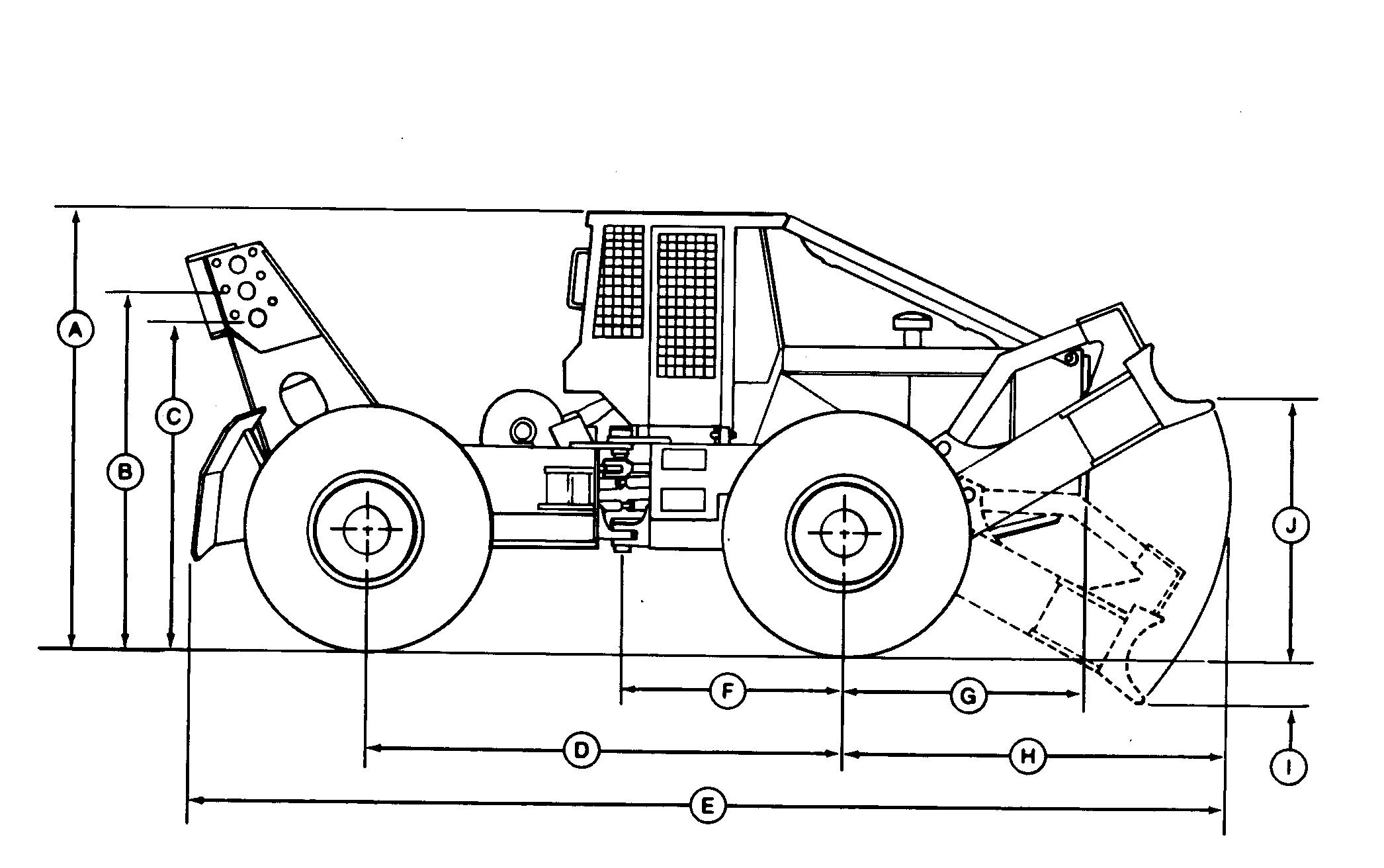

GeneralSpecifications

NOTE:Specificationsanddesignsubjecttochange withoutnotice.Wheneverapplicable, specificationsareinaccordancewithSAE Standardsunlessotherwisenoted,these

specificationsarebasedonastandard machinewith23.1L—2610PRLS2tires, adjustablelogarch,fullfueltankand79kg (175lb)operator.

ItemMeasurementSpecification

A—OverallHeightHeight3010mm(9ft11in.)

A—OverallHeightwithFactoryHeight3229mm(10ft7in.)

InstalledAirConditioning

B—MainFairleadRollerHeightHeight2110mm(6ft11.1in.)

C—AuxiliaryPositionFairleadRollerHeight1925mm(6ft3.8in.)

Height

D—WheelbaseDistance2920mm(9ft7in.)

E—OverallLengthLength6084mm(19ft11.5in.)

F—FrontAxletoArticulationJointDistance1575mm(5ft2in.)

ItemMeasurementSpecification

G—FrontAxletoFrontofMachineDistance1507mm(4ft11in.)

H—FrontAxletoBladeCuttingEdgeDistance2112mm(6ft11.1in.)

Arc

I—MaximumBladeDigDepthBelowDepth288mm(11.3in.)

Ground

J—MaximumBladeLiftAboveDistance1220mm(3ft11.6in.)

Ground

Continuedonnextpage

CED,OUO1040,162–19–16JUN98–2/4

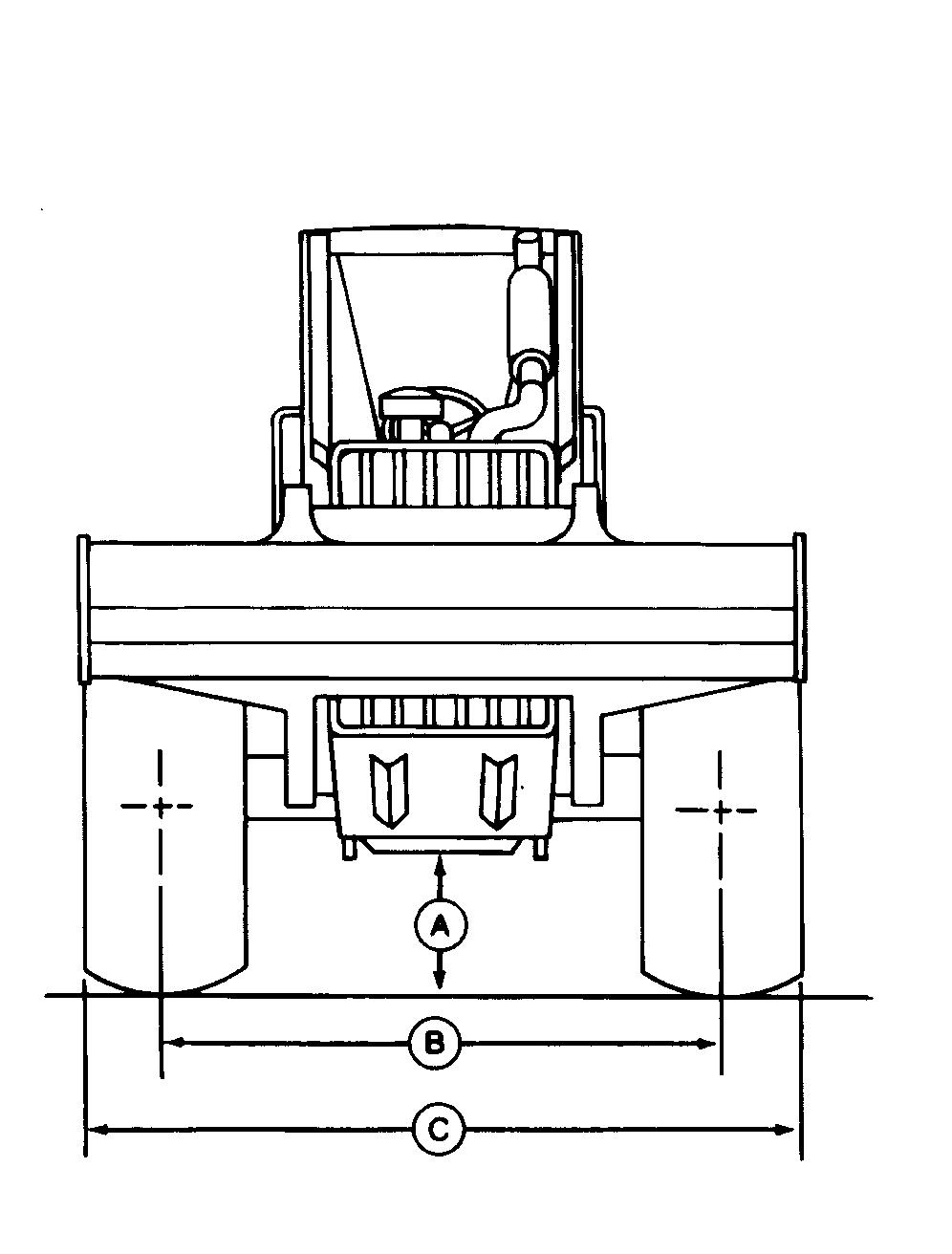

GeneralSpecifications

ItemMeasurementSpecification

TireSize:23.1—26

A—GroundClearanceClearance498mm(19.6in.)

B—WheelTreadDistance2.21m(7ft3in.)

C—OverallWidthWidth2.79m(9ft2in.)

TireSize:28L—26

A—GroundClearanceClearance514mm(20.2in.)

B—WheelTreadDistance2.29m(7ft6in.)

C—OverallWidthWidth3.0m(9ft10in.)

TireSize:23.1—26(NarrowGauge)

A—GroundClearanceClearance498mm(19.6in.)

B—WheelTreadDistance2.06m(6ft9in.)

ItemMeasurementSpecification

C—OverallWidthWidth2.64m(8ft8in.)

TireSize:28L—26(NarrowGauge)

A—GroundClearanceClearance514mm(20.2in.)

B—WheelTreadDistance2.18m(7ft2in.)

C—OverallWidthWidth2.9m(9ft6in.)

EngineSpecifications(S.N.—558324)

The5.9literengineisJohnDeereengineeredandmanufactured.Replaceablewettypecylinderlinersprovidesuperiorheatdissipation.High strengthalloycylinderheadshavereplaceablevalveseatinsertsforlongerservicelife.Castaluminumpistonsprovidegoodheattransfer whilepistonsaresprayedwithcoolingoilforlongerenginelife.Ahighefficiencyturbochargermaximizesengineperformance.

ItemMeasurementSpecification

Engine—JohnDeere6059Twith altitude-compensatingturbocharger (S.N.—558324)

RatedPower@2200rpmPower86kW(115nethp)

RatedPower@2200rpmPower90kW(120grosshp) CylindersQuantity6

FuelConsumption,TypicalUsage11.7—17.8L/h(3.1—4.7gal/hr)

MaximumNetEngineTorqueTorque30%@1400rpm465N•m(343 lb-ft)

ElectricalSystemVoltage12-volt

AlternatorAmperage95amps

BatteryCapacity180minutes,reserve Amps925coldcrankingamps

EngineSpecifications(S.N.558325—)

ThePowerTech 6.8literengineisJohnDeereengineeredandmanufactured.Replaceablewettypecylinderlinersprovidesuperiorheat dissipation.Highstrengthalloycylinderheadshavereplaceablevalveseatinsertsforlongerservicelife.Castaluminumpistonsprovidegood heattransferwhilepistonsaresprayedwithcoolingoilforlongerenginelife.Ahighefficiencyturbochargermaximizesengineperformance.

ItemMeasurementSpecification

Engine—JohnDeerePowerTech 6068Twithaltitude-compensating, spark-arrestingturbocharger(S.N. 558325—)

RatedPower@2200rpmPower89kW(119SAEnethp) PowerTechisaregisteredtrademarkofDeere&Company

ItemMeasurementSpecification

RatedPower@2200rpmPower95kW(127SAEgrosshp)

CylindersQuantity6

FuelConsumption,TypicalUsage14—21L/h(3.7—5.5gal/hr)

MaximumNetEngineTorqueTorque30%@1400rpm537N•m(398 lb-ft)

ElectricalSystemVoltage12-volt

AlternatorAmperage65amps

BatteryQuantityTwo12-Volt

540GSkidderForwardTravel Speeds1

Gear1Speed2.3km/h(1.4mph)

Gear2Speed3.2km/h(2.0mph)

Gear3Speed4.9km/h(3.0mph)

Gear4Speed6.4km/h(4.0mph)

Gear5Speed8.5km/h(5.3mph)

Gear6Speed11.1km/h(6.9mph)

Gear7Speed14.3km/h(8.9mph)

Gear8Speed24.8km/h(15.4mph)

540GSkidderReverseTravel Speeds

Gear1RSpeed3.1km/h(1.9mph)

Gear2RSpeed4.5km/h(2.8mph)

1At2200enginerpm,notireslipwith23.1—26tire.

ItemMeasurementSpecification

Gear3RSpeed6.8km/h(4.2mph)

Gear4RSpeed8.9km/h(5.5mph)

Hydraulics

Pump—@2200rpm,20684kPaFlowRate102L/min(27gpm) (3000psi)

CableArch HorizontalRollerDiameter152mm(6in.)

VerticalRollers(throughhardenedDiameter114mm(4.5in.) steel)

Weight OperatingWeightwithStandardWeight9980kg(22,000lb) Equipment

Steering

TurningRadiusOverTires(23.1—Distance5.47m(17ft11in.) 26tires)

TX,115,JC405–19–16JUN98–3/3

• Lubrication:

–Pressuresystemwithfull-flowfilter

• Transmission:

–Eightforward,fourreversespeeddirectdrive powershift

–Externallymountedchargepumpforeaseofservice

• Axles:

–1200SeriesTeamMate IIfrontandrearaxles

–Heavydutyinboardmountedplanetarytypegears thatdistributeshockloadsevenly

–Hydraulicallyapplieddifferentiallockinbothfrontand rearaxles

• Brakes:

–Hydraulicannularstylewetdiskbrakesareinboard mountedonfrontandrear

–Completelysealedrunninginacoolingoilbath

–Self-adjustingandself-equalizing

–Requirenoperiodicservice

–Spring-applied,hydraulically-released,wet multiple-discparkingbrakeistransmissionmounted

–Parkingbrakeautomaticallyappliedwhenengineis off

–Parkingbrakecanbemanuallyappliedbyplacingthe transmissioncontrolleverintheparkposition

• Steering:

–Aloadandspeedsensingpowersteeringsystem providesquickresponseandpowerforeasy maneuveringforwoodsoperations

–90° (45° eachdirection)offramearticulationprovides exceptionalmaneuverability

• Hydraulics:

–Axialpistonpressurecompensatedpumpformsthe heartofthequick,responsiveandpowerfulhydraulic system

–Closedcenterhydraulicsystemisseparatefrom transmissiontoenhanceoverallreliabilityofboth systems

GeneralSpecifications

Winch—4000Series

Winch: Thedirectdrive4000winchwithwetmultiplediscclutchandspringapplied,hydraulicallyreleasedbrakeisJohnDeereengineered andmanufactured.Lowfrictiondrumsealsandanadjustablefreespoolfeatureincreaseoperatingease.Itiscontrolledbyasingleleverthat hasbeenconvenientlylocatedfortheoperator.

CableCapacity: Calculatedwithnoallowancemadeforlooseorunevenspooling.

ItemMeasurementSpecification

4000SeriesWinch15.8mm(0.625 in.)Cable

8-in.DrumCapacity77.4m(254ft)

10-in.DrumCapacity60.6m(199ft)

4000SeriesWinch19.1mm(0.75 in.)Cable

8-in.DrumCapacity54.6m(179ft)

10-in.DrumCapacity43m(141ft)

4000SeriesWinch22.2mm(0.875 in.)Cable

8-in.DrumCapacity39.3m(129ft)

10-in.DrumCapacity30.8m(101ft)

4000SeriesWinch25.4mm(1.0in.)

Cable

8-in.DrumCapacity30.5m(100ft)

10-in.DrumCapacity23.8m(78ft)

4000SeriesWinch8-in.Drum StandardSpeed

BareDrumForce155kN(34,786lb)linepull@peak engineand15.8mm(0.625in.)

cable

GeneralSpecifications

ItemMeasurementSpecification

FullDrumForce95kN(21,437lb)linepull@peak engineand15.8mm(0.625in.)

cable

4000SeriesWinch8-in.DrumSlow Speed

BareDrumForce180kN(40,525lb)linepull@peak engineand15.8mm(0.625in.)

cable

FullDrumForce111kN(24,974lb)linepull@peak engineand15.8mm(0.625in.)

cable

4000SeriesWinch10-in.Drum

BareDrumForce147kN(32,985lb)linepull@peak engineand15.8mm(0.625in.)

cable

FullDrumForce111kN(24,974lb)linepull@peak engineand15.8mm(0.625in.)

cable

4000SeriesWinch8-in.Drum StandardSpeed

BareDrumSpeed44.5m/min(146fpm)linespeed@ 2200rpmand15.8mm(0.625in.)

cable

FullDrumSpeed73.8m/min(242fpm)linespeed@ 2200rpmand15.8mm(0.625in.)

cable

4000SeriesWinch8-in.DrumSlow Speed

BareDrumSpeed40.0m/min(131fpm)linespeed@ 2200rpmand15.8mm(0.625in.)

cable

ItemMeasurementSpecification

FullDrumSpeed66.4m/min(218fpm)linespeed@ 2200rpmand15.8mm(0.625in.)

cable

4000SeriesWinch10-in.Drum

BareDrumSpeed47.9m/min(157fpm)linespeed@ 2200rpmand15.8mm(0.625in.)

cable

FullDrumSpeed63.4m/min(208fpm)linespeed@ 2200rpmand15.8mm(0.625in.)

540GSkidderCapacities

ItemMeasurementSpecification

FuelTankCapacity157L(41.5gal)

CoolingSystemCapacity24.6L(26qt)

EngineLubrication(includingfilter)Capacity19L(5gal)

TransmissionCapacity29.3L(7.75gal)

FrontDifferential(1200SeriesAxle)Capacity17L(4.5gal)

RearDifferential(1200SeriesAxle)Capacity25L(6.5gal)

4000SeriesWinchCapacity35.2L(9.3gal)

HydraulicReservoirCapacity30.3L(8gal)

cable TX,115,JC410–19–17JUN98–1/1

CED,OUO1032,1139–19–10JUL98–3/3

548GGrappleSkidder

GeneralSpecifications

NOTE:Specificationsanddesignsubjecttochange withoutnotice.Wheneverapplicable, specificationsareinaccordancewithSAE Standardsunlessotherwisenoted,these

specificationsarebasedonastandard machinewith23.1L—2610PRLS2tires, adjustablelogarch,fullfueltankand79kg (175lb)operator.

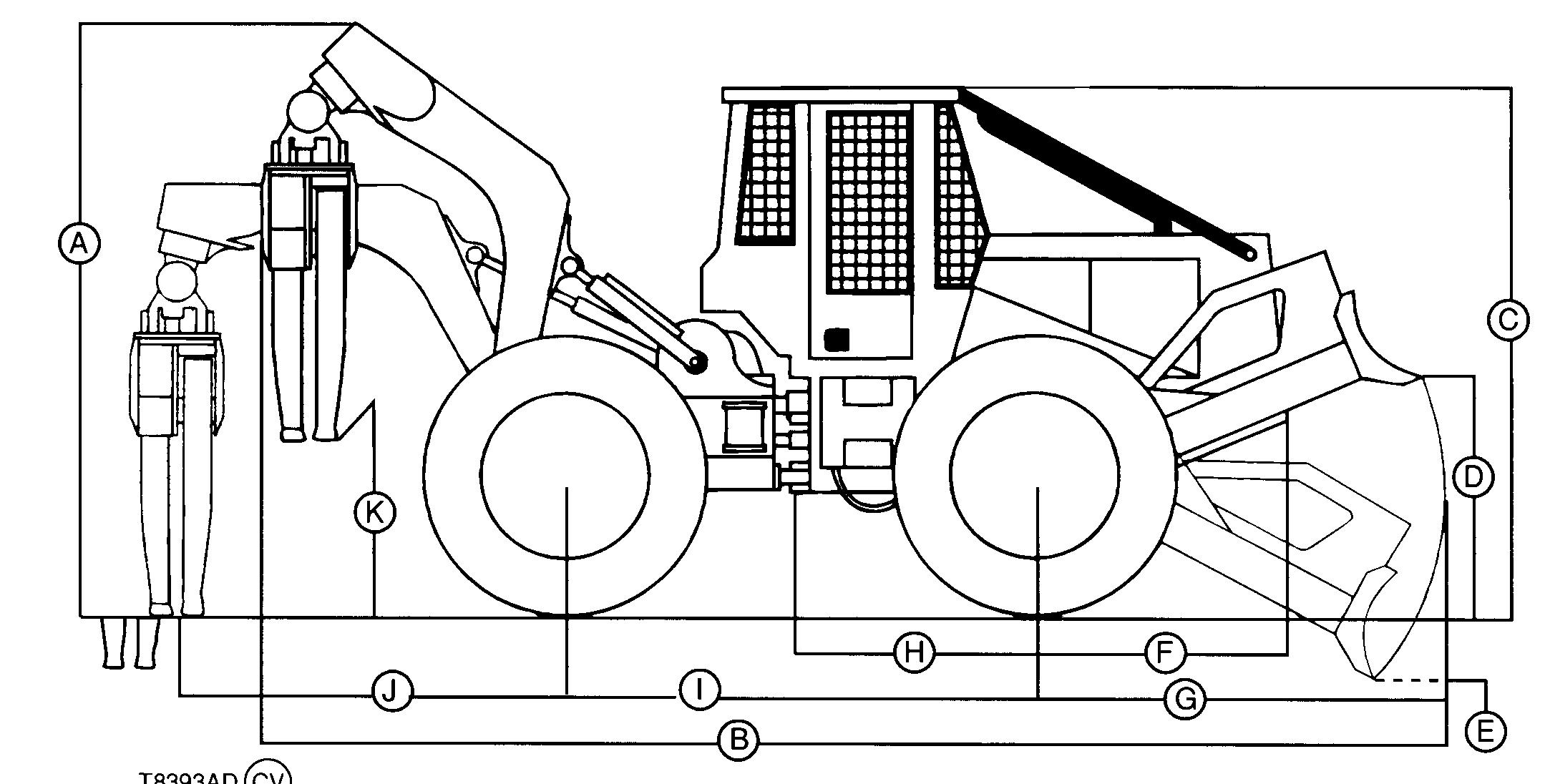

ItemMeasurementSpecification

A—OverallHeightofBoomHeight2991mm(9ft10in.)

B—OverallLengthLength6330mm(20ft9in.)

C—OverallHeightHeight3010mm(9ft11in.)

D—MaximumBladeLiftAboveDistance1210mm(3ft11.6in.)

Ground

E—MaximumBladeDigBelowDepth288mm(11.3in.)

Ground

F—FrontAxletoFrontofMachineDistance1507mm(4ft11in.)

G—FrontAxletoBladeCuttingEdgeDistance2112mm(6ft11in.)

Arc

H—FrontAxletoArticulationJointDistance1575mm(5ft2in.)

ItemMeasurementSpecification

I—WheelbaseDistance2920mm(9ft7in.)

J—ReachofGrappleatGroundDistance1970mm(6ft5.6in.)

Level

K—HeightofGrapplefromGroundHeight864mm(2ft10in.)

Level

Continuedonnextpage

CED,OUO1032,1140–19–10JUL98–2/4

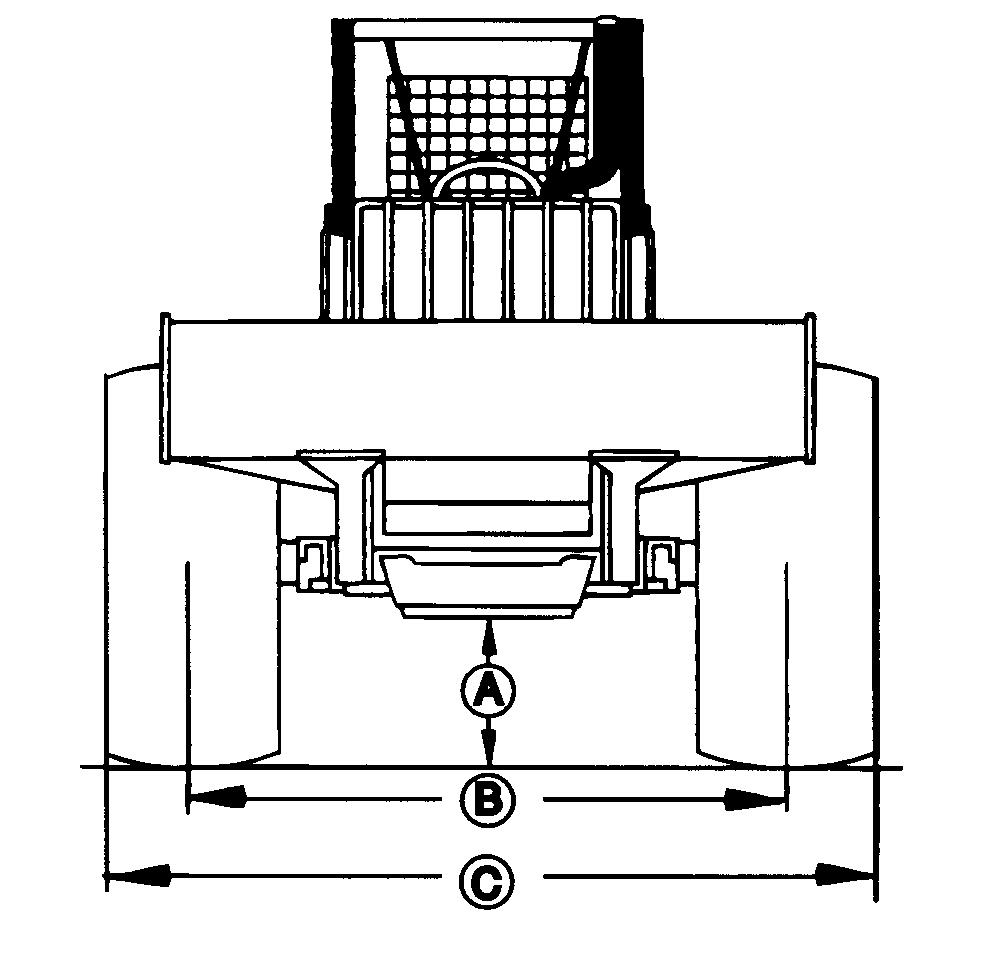

GeneralSpecifications

ItemMeasurementSpecification

TireSize:23.1—26

A—GroundClearanceClearance498mm(19.6in.)

B—WheelTreadDistance2.21m(7ft3in.)

C—OverallWidthWidth2.79m(9ft2in.)

TireSize:28L—26

A—GroundClearanceClearance514mm(20.2in.)

B—WheelTreadDistance2.29m(7ft6in.)

C—OverallWidthWidth3.0m(9ft10in.)

TireSize:23.1—26(NarrowGauge)

A—GroundClearanceClearance498mm(19.6in.)

B—WheelTreadDistance2.06m(6ft9in.)

C—OverallWidthWidth2.64m(8ft8in.)

TireSize:28L—26(NarrowGauge)

A—GroundClearanceClearance514mm(20.2in.)

ItemMeasurementSpecification

B—WheelTreadDistance2.18m(7ft2in.)

C—OverallWidthWidth2.9m(9ft6in.)

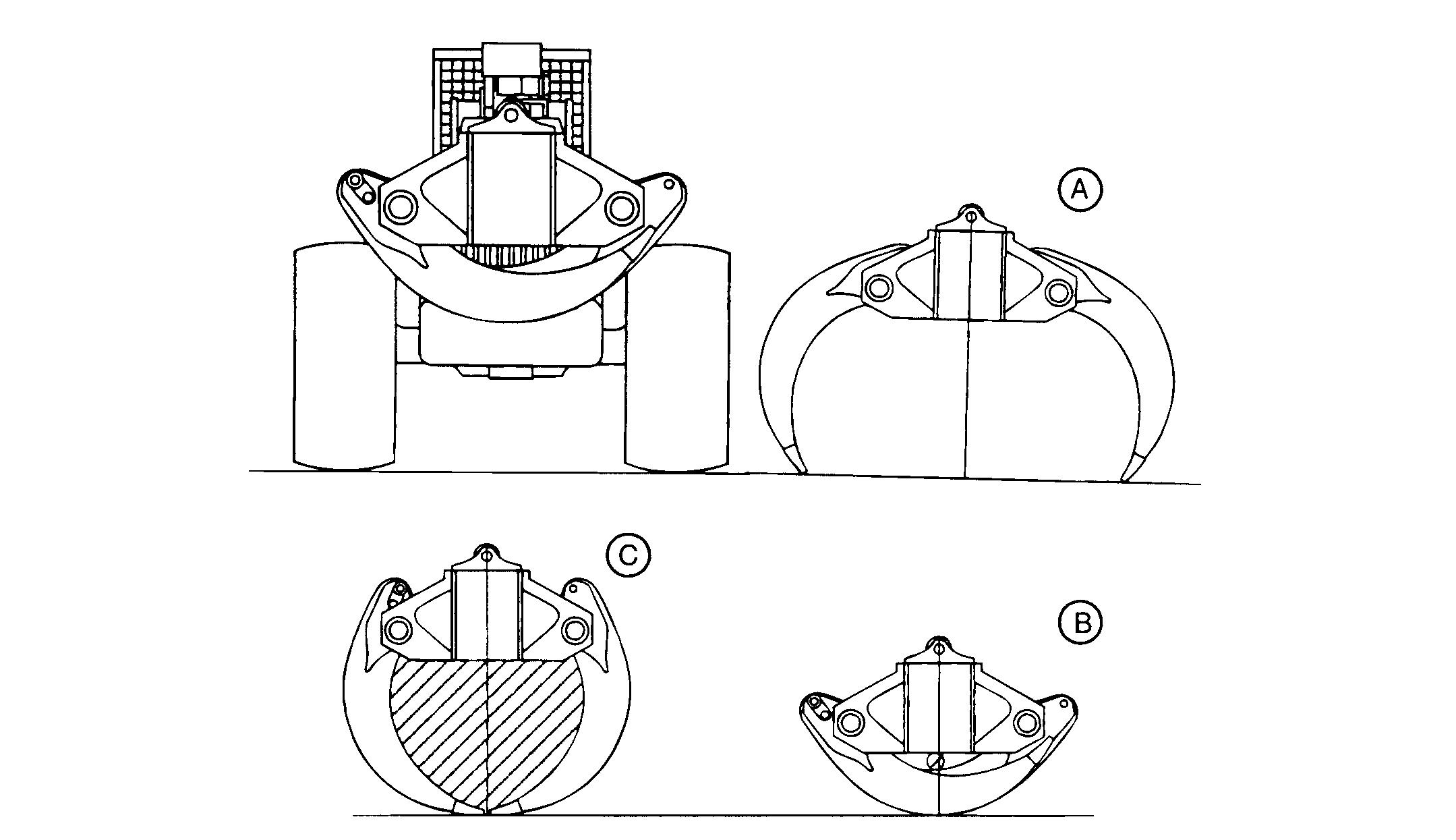

SingleFunctionGrappleSpecifications

CED,OUO1032,1140–19–10JUL98–4/4

ItemMeasurementSpecification

A—TongOpeningatTipsHeight2160mm(85in.)

B—MinimumDiameterofStemDiameter124mm(5in.)

C—EnclosureArea,TongsTip-to-TipArea0.75sqm(8sqft)

CED,OUO1032,1129–19–01JUL98–1/1

548GGrappleSkidderEngineandSystem Specifications

EngineSpecifications(S.N.—558324)

The5.9literengineisJohnDeereengineeredandmanufactured.Replaceablewettypecylinderlinersprovidesuperiorheatdissipation.High strengthalloycylinderheadshavereplaceablevalveseatinsertsforlongerservicelife.Castaluminumpistonsprovidegoodheattransfer whilepistonsaresprayedwithcoolingoilforlongerenginelife.Ahighefficiencyturbochargermaximizesengineperformance.

ItemMeasurementSpecification

Engine—JohnDeere6059Twith altitude-compensatingturbocharger (S.N.—558324)

RatedPower@2200rpmPower86kW(115nethp)

RatedPower@2200rpmPower90kW(120grosshp) CylindersQuantity6

FuelConsumption,TypicalUsage11.7—17.8L/h(3.1—4.7gal/hr)

MaximumNetEngineTorqueTorque30%@1400rpm465N•m(343 lb-ft)

ElectricalSystemVoltage12-volt

AlternatorAmperage65amps

BatteryCapacity180minutes,reserve Amps925coldcrankingamps

EngineSpecifications(S.N.558325—)

ThePowerTech 6.8literengineisJohnDeereengineeredandmanufactured.Replaceablewettypecylinderlinersprovidesuperiorheat dissipation.Highstrengthalloycylinderheadshavereplaceablevalveseatinsertsforlongerservicelife.Castaluminumpistonsprovidegood heattransferwhilepistonsaresprayedwithcoolingoilforlongerenginelife.Ahighefficiencyturbochargermaximizesengineperformance.

ItemMeasurementSpecification

Engine—JohnDeerePowerTech 6068Twithaltitude-compensating, spark-arrestingturbocharger(S.N. 558325—)

RatedPower@2200rpmPower89kW(119SAEnethp)

PowerTechisaregisteredtrademarkofDeere&Company

ItemMeasurementSpecification

RatedPower@2200rpmPower95kW(127SAEgrosshp)

CylindersQuantity6

FuelConsumption,TypicalUsage14—21L/h(3.7—5.5gal/hr)

MaximumNetEngineTorqueTorque30%@1400rpm537N•m(398 lb-ft)

ElectricalSystemVoltage12-volt

AlternatorAmperage65amps

548GGrappleSkidderForward TravelSpeeds1

Gear1Speed2.3km/h(1.4mph)

Gear2Speed3.3km/h(2.1mph)

Gear3Speed5.0km/h(3.1mph)

Gear4Speed6.5km/h(4.1mph)

Gear5Speed8.7km/h(5.4mph)

Gear6Speed11.3km/h(7.1mph)

Gear7Speed14.6km/h(9.1mph)

Gear8Speed25.3km/h(15.7mph)

548GGrappleSkidderReverse TravelSpeeds

Gear1RSpeed3.2km/h(2.0mph)

Gear2RSpeed4.6km/h(2.8mph)

1At2200enginerpm,notireslipwith28L—26tire.

ItemMeasurementSpecification

Gear3RSpeed6.9km/h(4.3mph)

Gear4RSpeed9.1km/h(5.6mph)

Hydraulics

Pump—@2200rpm,20684kPaFlowRate102L/min(27gpm) (3000psi)

Weight

OperatingWeightwithStandardWeight9861kg(21,740lb) Equipment

Steering

TurningRadiusOverTires(28L—Distance5.51m(18ft9in.) 26tires)

CED,OUO1032,1141–19–10JUL98–3/3

548GGrappleSkidderOtherInformation

• Lubrication:

–Pressuresystemwithfull-flowfilter(S.N.—558324)

–Pressuresystemwithoilcooler(S.N.558325—)

• Transmission:

–Eightforward,fourreversespeeddirectdrive powershift

–Externallymountedchargepumpforeaseofservice

• Axles:

–1200SeriesTeamMate IIfrontandrearaxles

–Heavydutyinboardmountedplanetarytypegears thatdistributeshockloadsevenly

–Hydraulicallyapplieddifferentiallockinbothfrontand rearaxles

• Brakes:

–Hydraulicannularstylewetdiskbrakesareinboard mountedonfrontandrear

–Completelysealedrunninginacoolingoilbath

–Self-adjustingandself-equalizing

–Requirenoperiodicservice

–Spring-applied,hydraulically-released,wet multiple-discparkingbrakeistransmissionmounted

–Parkingbrakeautomaticallyappliedwhenengineis off

–Parkingbrakecanbemanuallyappliedbyplacingthe transmissioncontrolleverintheparkposition

• Steering:

–Aloadandspeedsensingpowersteeringsystem providesquickresponseandpowerforeasy maneuveringforwoodsoperations

–90° (45° eachdirection)offramearticulationprovides exceptionalmaneuverability

• Hydraulics:

–Axialpistonpressurecompensatedpumpformsthe heartofthequick,responsiveandpowerfulhydraulic system

–Closedcenterhydraulicsystemisseparatefrom transmissiontoenhanceoverallreliabilityofboth systems

• Grapple:

–Engineeredtoprovidedurabilityandperformace

–Greaseadjustableoscillationdamperimproves componentlifeandreducesmaintenancerequirements

–Constantpressuretokeepgrappleclosedontheload isstandard

–Shapeandclampingforcehavebeenengineeredto maximizeloadretention

CED,OUO1032,1142–19–10JUL98–2/2