U.S. 101 Marin–Sonoma Narrows Widening and Flood-Control Project

SUBCONTRACTOR FOCUS

U.S. 101 Marin–Sonoma Narrows Widening and Flood-Control Project

SUBCONTRACTOR FOCUS

0% FOR 60 MONTHS + SECTION 179 TAX BENEFITS

End the year with the right equipment and real savings. 0% for 60 months on John Deere compact machines, plus Section 179 tax benefits that help you save even more. Upgrade your fleet, reduce your tax burden, and get ready for the year ahead.

And that’s not all — when you purchase a qualifying machine, you’ll also get $500 off select John Deere attachments. It’s the perfect time to complete your fleet and get the job done right.

*Offer valid on qualifying purchases made 08 October 2025 through 02 January 2026. Subject to approved installment credit with John Deere Financial, for commercial use only. No payments, and no interest for 3 months followed 0% APR for 60 months. Payments will begin at the end of the third month from contract date. Taxes, freight, setup, fees, and delivery charges could increase monthly payment. Some restrictions apply, so see your dealer for complete details and other financing options. Available at participating U.S. dealers. Prices may vary by dealer.

www.coastlineequipment.com

YOUR AUTHORIZED JOHN DEERE DEALER FOR THESE CA COUNTIES:

Long Beach Branch – Los Angeles and Orange

Oxnard Branch – Northern Los Angeles, Ventura and Santa Barbara

Santa Maria Branch – San Luis Obispo and Santa Barbara

Bakersfield Branch – Kern, Inyo, Mono and Eastern Los Angeles Lake Forest and Sylmar Branches – Parts Only Stores

VCES brings you the Volvo A60, built for unmatched productivity and control. With advanced features like Haul Assist with On-Board Weighing, Connected Map, and CareTrack telematics, you’ll move more with less effort. Backed by Volvo Service Contracts, the A60 delivers reduced fuel use, less wear, and maximum uptime — keeping your operation efficient, reliable, and ready for any challenge.

C ontact your nearest VC E S location today

Larkspur’s pedestrian and bicycle bridge is a key link in the Central Marin Ferry Connection Multi-Use Pathway, helping close a major gap in the North–South Greenway and creating a seamless route to the Larkspur Ferry Terminal and Cal Park Hill Tunnel.

By Brian Hoover / Photos provided by Ghilotti Bros., Inc.

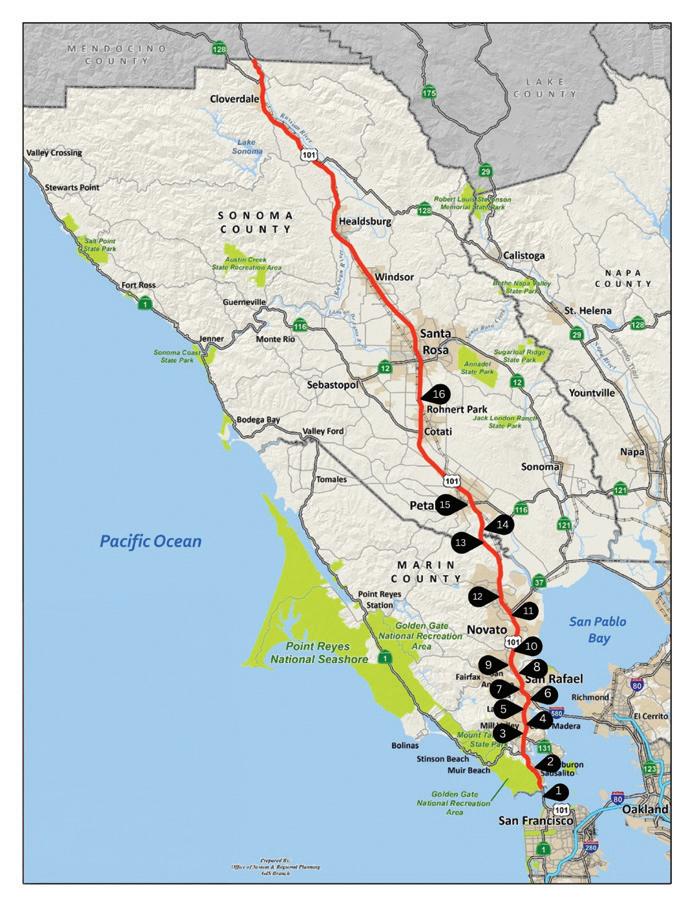

For more than three decades, commuters in Marin and Sonoma counties measured their mornings and evenings against the bottleneck of U.S. 101, the notorious Marin–Sonoma Narrows. When the final lanes opened on September 29, 2025, traffic eased almost overnight. “People got 20–30 minutes of their lives back,” said Mike Ghilotti, President & CEO of Ghilotti Bros., Inc. “It was a gratifying validation for our family firm that delivered multiple segments

of the corridor and weathered a few storms along the way.”

Based in San Rafael, Ghilotti Bros. (GBI) has shaped much of Northern California’s infrastructure north of the Golden Gate, from median barriers and paving through the Robin Williams Tunnel to bridge and flood-control improvements in Petaluma and San Antonio Creek. Though the company didn’t hold the final Narrows contract (that bid was won by a cousin’s firm), its imprint across the corridor is

unmistakable: 16 of the 19 projects along the 101 corridor from the Golden Gate Bridge to Rohnert Park including the Marin Sonoma Narrows Program were delivered by GBI.

Among the most memorable chapters for GBI was the Petaluma River Bridge, a long steel-girder structure built under a line-item joint venture. Responsibilities were

1. Golden Gate Bridge Moveable Median Barrier San Francisco

2. 101 North and South bound overlays

3. US 101 Greenbrae Interchange Improvements

4. Central Marin Ferry Connection Pedestrian Overcrossing Larkspur

5. Cal Park Hill Overlay San Rafael

6. Richmond San Rafael Bridge to Hwy 101/580 Separation San Rafael

7. Hwy 101 Bellam Blvd Off Ramp widening San Rafael

8. Lincoln Ave Improvements and Hwy 101 RR Bike Lane San Rafael

9. Hwy 101 Freitas Parkway new round-about San Rafael

10. Hwy 101 HOV Lanes – Central San Rafael to North San Pedro Road San Rafael

11. Hwy 101 NB HOV Lane from SR 37 to Atherton Ave, SB SR 37 to Novato Creek Novato

12. Hwy 101 from Novato Creek to Franklin Overhead, extend SB HOV lane Novato

13. Realigned Hwy 101 at San Antonio Road, renovated San Antonio Creek Bridge Petaluma

14. Modify Petaluma Blvd South interchange and frontage roads and replace Petaluma River Bridge Petaluma

15. Replace NB Hwy 101 bridge over SR 116, widen SB bridge, reconstruct ramps and sound wall Petaluma

16. Widen Hwy 101 at Wilfred Ave Rohnert Park

divided, the partner handled the bridge superstructure while GBI self-performed the roadway approaches, grading, and civil scopes.

Two unforeseen challenges reshaped the project. First, a bird-protection measure backfired when nesting swallows became trapped in safety netting, prompting months of biologist oversight and schedule delays. Then, late in the job, the JV partner suffered financial distress, leaving

unpaid balances to subcontractors. When the surety declined to honor the JV’s structure, Ghilotti Bros. stepped up, advancing roughly $3 million to keep crews working and the project on track.

“We could have stopped and pointed fingers,” said Ghilotti. “Instead, we reorganized, brought in bridge hands, and poured the deck ourselves, the first bridge deck in our 111-year history.”

Despite the setback, GBI completed the bridge on schedule,

later negotiating partial recovery of the loss. The bridge went on to earn industry awards and remains a defining example of the company’s persistence and professionalism.

Following the Petaluma success, GBI tackled the Route 101 Widening and Flood-Control Project near San Antonio Creek, a low-lying, flood-prone area straddling the

A Ghilotti CAT excavator and dozer tackle grading work along U.S. 101 at Lincoln as part of the ongoing improvements within the Marin–Sonoma Narrows corridor. This stretch of work supports a series of major upgrades extending from Novato Creek to Petaluma, including HOV lane extensions, highway realignment near San Antonio Road, bridge renovations, and multiple interchange enhancements designed to relieve congestion and improve long-term mobility along one of the region’s busiest corridors.

concrete replacement supported by deep piles. To maintain live traffic, GBI constructed temporary detours and drainage facilities, an impressive logistical feat given the constrained right-of-way. This work wrapped around 2021–2022, setting the stage for the corridor’s final segment built by another construction firm.

Marin–Sonoma county line. Under Caltrans direction, GBI realigned the highway onto higher ground and widened it from two lanes to three in each direction to improve safety and sight distance.

The $45.7 million contract included 620,000 cubic yards of excavation, new drainage systems, 11,000 linear feet of storm-drain facilities, and 1,600 linear feet of retaining walls. The firm also demolished the old bridge and then JV partner built a new 500-foot

Across more than two decades of corridor contracts, Ghilotti Bros. consistently championed Caltrans partnering principles that emphasized collaboration, accountability, and shared success. The firm worked closely with Caltrans District 4, the Sonoma County Transportation Authority, and the Transportation Authority of Marin, supported at times by Ventura Consulting Group, to establish “big, audacious goals” that drove efficiency and value engineering.

“On our best jobs you couldn’t tell who worked for Ghilotti or Caltrans,” said Ghilotti. “It was just about the job.”

GBI’s collaborative culture earned them the 2021 IPI Partnered Project of the Year Award, recognizing their ability to keep projects advancing under challenging conditions. GBI earned a total of 27 partnering awards during the span of this project.

Working under live traffic conditions brought intense safety demands, and sobering reminders of real-world risk. During the San Antonio Creek phase, a catastrophic DUI incident occurred when an impaired driver breached traffic controls and landed on a partially built bridge. Despite clear intoxication, the event led to a multimillion-dollar settlement.

“California’s liability framework keeps pushing contractors toward more protection, more cost, well beyond other states, yet we’re still blamed when personal responsibility evaporates,” Ghilotti reflected. “That pressure and liability ultimately land on public budgets and insurance.”

[ Continued on page 10 ]

The JCB 370X has been tested to extremes. Every element of this class-leading 35–40-ton excavator is designed to deliver enhanced performance and reliability.

The 370X is the toughest, strongest and most powerful excavator from JCB, bringing extra levels of productivity and efficiency to your site.

We’re thrilled to announce that the first machine to incorporate JCB UX excavator software is our all-new JCB 370X

EFFICIENCY

With a powerful and efficient Cummins engine, refined hydraulics and a host of advanced features to maximize productivity – you can trust this JCB excavator to get the job done, fast.

Right and Below: For the Marin–Sonoma Narrows (US 101) Project, the contractor Ghilotti Bros. is working on the final sub-project (MSN B7), which covers a ~3.5-mile section between north Novato (Marin County) and the Marin-Sonoma County line. Within that scope they are placing more than 200,000 tons of asphalt pavement along with significant earth-moving, subgrade remediation and two bridge widenings.

{ Continued from page 8 }

According to Ghilotti, when the last Narrows lanes opened, congestion relief was immediate, particularly in the evenings. But changes to HOV-lane policies soon dampened some of the morning gains. “Standardizing HOV hours to much longer windows jammed the a.m. commute,” said Ghilotti. “The fix worked on the northbound but then the southbound got undone by the rulebook.” He remains

optimistic adjustments will restore balance, underscoring how operational decisions can quickly influence the public’s perception of construction outcomes.

Ghilotti Bros.’ current slate extends well beyond highways. The firm recently partnered with Stacy & Witbeck on the SMART Corona Road Station in Petaluma, blending rail, civil, and site work, a project that received the APWA Norcal

Transportation (small cities/rural communities) award.

In Napa’s Coombs Street streetscape, the company again applied its partnering mindset to navigate modern challenges: shallow utilities, incomplete as-builts, and shifting design responsibilities. “Institutional knowledge has thinned,” said Ghilotti. “Contractors are increasingly asked to finish the design under the gun. Mentorship between veteran builders and the next generation would save time and money.”

Work along the U.S. 101 corridor includes improvements from Novato Creek to Franklin Overhead, extension of the southbound HOV lane, realignment near San Antonio Road with a renovated San Antonio Creek Bridge, and multiple upgrades in Petaluma— including the Petaluma Blvd. South interchange, frontage roads, the Petaluma River Bridge, and the SR-116 bridge and ramps.

Now in its fourth generation of family leadership, Ghilotti Bros. is three years into a seven-year succession roadmap to ensure a thoughtful transition to Mike Ghilotti’s son, Gino. The oldest son, Mario, left the company to start his own development company Vero-West, and daughter Angelina

works in the company’s finance department, while the youngest son, Giovanni, pursues a career in the film industry. “Structure matters,” he said. “You can’t just say, ‘Stick around and someday this will be yours.’ You need a plan that gives the next generation visibility, accountability, and opportunity.”

Beyond construction, GBI invests in the next generation of builders through the North Bay Construction Corps, a semester-long tradesexposure program for high-school seniors. Mike Ghilotti is passionate about introducing young people to debt-free career paths in the trades that lead to homeownership and financial stability. “Whether you come with a degree or straight from high school, you still have to prove you can do the work,” said

Ghilotti. “The trades offer a head start a lot of people don’t realize is there waiting for them.”

Today, motorists traveling between the Golden Gate Bridge and Petaluma can see the tangible results of Ghilotti Bros.’ craftsmanship, flood-resistant bridges, improved drainage, and safer lanes that strengthen one of Northern California’s most vital corridors. For Ghilotti Bros., Inc., the Marin–Sonoma Narrows work stands as both a technical achievement and a symbol of resilience, a story of family leadership, teamwork, and the determination to build smarter, safer, and stronger for the future. For more information about Ghilotti Bros., Inc., visit www.gbi1914.com or call their San Rafael headquarters at (415) 454-7011. Cc

rich@redhaulexp.com www.redhaulexp.com

In the wake of the Dixie Fire, Caltrans and Pavement Recycling Systems delivered sustainable roadway reconstruction using Full Depth Recycling with Foamed Asphalt and Cement.

In 2021, the Dixie Fire scorched vast swaths of Northern California, leaving the Lake Almanor region devastated. Entire communities were reduced to ash, and critical infrastructure, including roads, suffered extensive damage. Since then, recovery has been slow but steady, with Caltrans leading the charge to restore vital transportation corridors.

Among the most significant efforts on the south side of the lake was the reconstruction of 12 miles of Highway 89, stretching from the Town of Chester to the Canyon Dam area. This corridor, essential

for local mobility and tourism, required a complete overhaul due to the age of the road and the impact of the fire.

Prime contractor Dig It Construction managed the overall rehabilitation effort, which included drainage improvements, shoulder widening, safety upgrades, and the removal of fire-damaged trees along the route. The contract called for a full roadway rebuild, rehabilitating the pavement structure, improving drainage, and repaving the corridor to modern standards.

Pavement Recycling Systems (PRS), a leader in sustainable road construction, was brought in to execute the pavement rehabilitation. Known for its expertise in asphalt grinding, soil stabilization, and both full and partial depth recycling, PRS

performed a Full-Depth Recycling with Foamed Asphalt and Cement (FDR-FA) on the western half of the project.

As Caltrans continues to expand its sustainability-focused initiatives, new guidance and improved specifications are shaping the future of in-place recycling across the state. “Through the newly established Caltrans Office of Pavement Recycling and Job Order Contracts, Caltrans has been updating and developing specifications for cold-recycling processes for pavement maintenance and rehabilitation applications,” said Marco A. Estrada, Pavement Recycling Director of Market Development.

Daryl Pollak, Chief Estimator for the company’s Northern California Division, successfully bid the project. Once awarded, the PRS team, led by Jim Thomason,

superintendent, got to work. PRS worked closely with the prime contractor and Caltrans to ensure operations were ready to go. Thomason was assisted by many others within PRS, sharing their expertise to maximize the quality of the FDR process. Pavement Engineering Inc, out of Redding California was hired by PRS to sample the existing roadway and develop mix designs that were approved by Caltrans. FDR-FA is an engineered process that recycles existing pavement inplace. It involves injecting foamed asphalt into the mixing chamber of a reclaimer, where it blends with pulverized asphalt or reclaimed asphalt pavement (RAP). The foam, created by combining hot liquid asphalt with cold water, expands and coats the aggregate, forming a durable, compacted base ready for asphalt overlay.

On this project, PRS used two Wirtgen WR 250i reclaimer mixers, which according to Pollak is considered the industry standard for pavement recycling. “These Wirtgen machines are the heart of the operation,” said Pollak. “They pulverize the existing pavement, mix in the cement, and inject the foamed asphalt binder all in one continuous process.”

PRS coordinated directly with Nixon-Egli Equipment Company and Wirtgen technical support, who both assisted on-site to ensure proper calibration and performance. “It had been several years since Caltrans used this specific foamed asphalt process, so Wirtgen sent out a technician to verify that everything was dialed in to precision,” Pollak added. “Their support was invaluable in keeping production running smoothly.”

The PRS team pulverized the existing asphalt and base materials to a depth of eight inches, simultaneously blending in foamed asphalt and cement to create a stabilized subbase. The hot asphalt oil, heated to over 300°F, was pumped from an oil tanker into the mixer, where a small amount of water was added to create the foamed asphalt

“As the mixer moves down the roadway, it pulverizes and blends everything together,” explained Pollak. “The foamed asphalt coats the recycled aggregate, the cement is mixed in as a binder, and it’s all compacted and graded immediately after. What you end up with is a strong, uniform base that cures and is ready for paving within days.”

PRS completed this coordinated operation using a configuration

consisting of an oil truck, water truck, and reclaimer, followed by compactors and graders. Once the base cured, crews placed approximately 4.5 inches of new asphalt concrete (AC) in two lifts, totaling more than 85,000 tons of new asphalt material.

Despite the complexity of the project and Caltrans’ use of the FDR-FA application, PRS overcame several logistical challenges. These included managing live traffic and coordinating around short construction windows.

“Foamed asphalt requires specialized equipment and experienced contractors,” said Pollak. “Caltrans has used this process before, and with their current emphasis on sustainability, they are looking to expand its use because it delivers excellent

long-term performance and cost efficiency.

Originally scheduled for 2026, the project timeline was accelerated thanks to strong summer progress by Dig It Construction. PRS mobilized quickly, completing its scope in September, well ahead of schedule, and ensuring optimal conditions for final paving before the onset of colder weather.

PRS’s role in the Highway 89 reconstruction reflects its broader mission: to deliver highperformance, environmentally responsible solutions that stand the test of time. Their contribution not only restored a critical transportation link but also demonstrated the power of innovation and collaboration in post-disaster recovery.

From a sustainability standpoint, full-depth recycling is a win on multiple levels. “You’re essentially reusing materials that Caltrans already paid for decades ago to rebuild the new roadway,” Pollak noted. “Instead of removing and hauling off old materials, we turn them into a strong recycled base right in place. That means fewer truck trips, less fuel consumption, reduced emissions, and most importantly improved project safety conditions.”

PRS often refers to this concept as the “urban quarry,” a term coined by the Recycling Stabilization Association (RSA), reflecting the idea of mining the materials already present in roadways rather than sourcing new aggregates. “As natural resources become harder to obtain and more expensive, processes like this are vital,” said [ Continued on page 18 ]

At G3 Equipment AC Specialists, we provide expert AC repair services for commercial fleets. Our skilled technicians ensure your systems operate safely and efficiently— keeping your vehicles running smoothly and your drivers safe and comfortable.

RED DOT Roof Top

Air Central

Mobile AC Hoses

{ Continued from page 16 }

Pollak. “They allow agencies to stretch their budgets, complete projects faster, and make more sustainable choices.”

With Caltrans’ focus on sustainability and the advancement of the Cold Recycling processes, Pollak hopes projects like Highway 89 will encourage more agencies to adopt the technique. “Every time we complete one of these, it builds confidence,” he said. “This approach is faster, more sustainable, and produces exceptionally durable roadways — which is why we anticipate increasing adoption by Caltrans and other agencies.”

As the Lake Almanor community continues to rebuild, projects like this stand as a testament to resilience, and to the value of sustainable infrastructure practices in shaping a stronger future.

Pavement Recycling Systems remains committed to advancing that vision through innovation, collaboration, and a steadfast dedication to quality.

Pavement Recycling Systems, Inc. (PRS), a 100% employee-owned company, has long been at the forefront of in-place pavement recycling across the western United States. The company’s approach to Full-Depth Recycling with Foamed Asphalt (FDR-FA) represents one of the most advanced, sustainable, and costeffective methods for rebuilding roadways without removing and replacing the existing materials. At its core, the process transforms the old pavement and base into a renewed, highperformance foundation. For transportation agencies, this

method delivers a durable, and stable pavement foundation. For contractors, it provides a faster, cleaner operation with fewer logistical challenges and minimal disruption to traffic. And for communities, it means safer, quieter, and more sustainable infrastructure renewal.

As Pavement Recycling Systems continues to expand its services throughout California and beyond, projects like the Highway 89 reconstruction near Lake Almanor highlight how modern full-depth recycling with foamed asphalt is redefining the way we think about roadway rehabilitation, proving that sometimes, the best new roads are built from the old ones.

For more information on FDR-FA and other sustainable pavement methods available at PRS, please visit www.pavementrecycling.com or contact Marco A. Estrada directly at 951-205-6000. Cc

With innovative GPS and grade control technology, these machines deliver the reliability, efficiency, and profitability you need to get the job done.

Sunbelt Rentals is now a proud Rental Partner of SITECH Pacific an authorized Trimble dealer.

5 EARTH MOVING SOLUTIONS LOCATIONS TO SERVE CALIFORNIA

BAKERSFIELD

9631 Enos Lane Bakersfield, CA 93314 (661) 746-6762

ESCONDIDO

530 N. Andreasen Drive Escondido, CA 92029 (760) 737-0307

SIGNAL HILL

2508 N. Palm Drive #200 Signal Hill, CA 90755 (562) 595-6655

TRACY 26508 Banta Road Tracy, CA 95304 (209) 855-8477

PHOENIX, AZ 12328 W. Butler Drive El Mirage, AZ 85335 (480) 494-4310

By Brian Hoover / Photos provided by CPP

Equipment theft has long plagued the construction industry, but recent years have seen an alarming rise in both frequency and sophistication.

According to Melissa Somers, Executive Director of Crime Prevention Program of Southern California (CPP), the issue has evolved far beyond petty thefts of small tools or trailers. Today’s thieves are organized, wellequipped, and increasingly targeting high-value machinery.

“We’ve seen a massive increase in thefts, especially of newer and larger equipment,” Somers explains. “In fact, since 2019 the total value of equipment stolen has risen by nearly 200%. Thieves aren’t going after small towables anymore, they’re stealing full-size backhoes and loaders right off job sites.”

CPP serves primarily Southern California but provides support wherever it’s requested or needed.

CPP is one of the most engaged and proactive theft prevention programs I have ever worked with during my career. With crime continuing to rise, CPP is on the forefront with technology and connections to the resources needed to both prevent theft and in the case of theft, recovery. We value our partnership with them and promote the benefits of being a member of CPP to all our customers and vendors.”

– Ladd Blakely, Branch Manager, Coastline Equipment

Somers’ mission is to bridge a critical communication gap between contractors, equipment and rental companies, and law enforcement.

“Everyone cares, contractors, rental companies, police, but we’re not always communicating effectively,” she says. “Contractors sometimes assume police don’t care, and law enforcement feels

Melissa Somers, Executive Director of Crime Prevention Program of Southern California (CPP).

contractors don’t secure their equipment. The truth is everyone’s trying to do the right thing. We just need someone to bridge the existing gap in communication so we can work together and more effectively.”

Gone are the days when thieves would steal a skid steer, stash it around the corner, and wait to see if anyone noticed. Today’s criminals use technology to stay a step ahead.

“They’re finding and removing GPS trackers using scanners,” Somers says. “That’s a big frustration because a lot of companies think, ‘We’ve got GPS, so we’re covered.’ Unfortunately, that’s not true anymore.”

Somers advocates a layered approach to protection, combining GPS with simple deterrents like locking devices, clear company markings, and CPP’s own Reward Hotline decals.

“If you have two identical machines, but one is clearly marked with CPP suggested owner

applied information while the other is not, a thief is much more likely to choose the easier target,” she says. “Prevention is in our name, we strive to help you make your equipment less appealing to thieves in the first place.”

While many assume insurance will cover the loss, Somers reminds contractors that theft carries significant hidden costs.

Lost time, project delays, higher premiums, and deductibles all add up, especially as replacement equipment remains back ordered and expensive.

“It’s not just about the replacement value,” she says. “It’s about downtime, frustration, and the ripple effect it causes on job schedules.”

CPP acts as a liaison between law enforcement and its members, which include major contractors and sales and rental companies like Sukut, Savala, Atkinson, Quinn Cat, Coastline Equipment, United Rentals, and Sunbelt.

When a theft occurs, CPP ensures that the report is properly filed, entered, and circulated among task forces.

“If a stolen piece of equipment isn’t entered into the national stolen system,” Somers explains, “an officer could pull over the thief and let them go simply because it’s not flagged as stolen.”

CPP’s law-enforcement partnerships can also greatly improve response times when GPS tracking is active.

“We work directly with auto theft task forces throughout the state. So, when a member has a theft with a live GPS signal, we reach out directly to our contacts which can move a case from low priority to immediate response,” she says. “That’s where our relationships really pay off.”

How are criminals accessing job sites so easily? Often, by blending in.

“They look the part,” Somers says. “They show up in vests and hard hats, load equipment onto a trailer, and drive off like they belong there. It’s quite common for thefts to happen in plain sight.”

She urges contractors to use creativity and common sense, sometimes the simplest fixes are the most effective.

“One of our members was getting hit with a lot of battery theft on a freeway job. He starting using reflective road-dots to secure the

Layered security works, and CPP accelerates recovery,” says Oskorus. “Clean reporting and fast law-enforcement liaison make the difference between loss and return.”

batteries in his equipment, so if someone tried to remove them, they’d destroy the battery. It sounds odd, but it worked.”

Cameras, solar-powered surveillance towers, and remote monitoring systems have also become valuable tools, but only when used effectively.

“Footage of ‘a guy in a black hoodie’ isn’t as helpful as we’d like it to be,” Somers notes. “We encourage companies to capture license plates, vehicle details, and share them with us immediately. CPP gathers this kind of information in the event it proves to be useful for more than just your theft. When warranted, we share it with law enforcement to help with their investigations. The more specific the data, the better the chance of recovery or even arrest.”

“CPP plays a critical role in recovering stolen contracting equipment, and our partnership through the Taskforce for Regional Autotheft Prevention (T.R.A.P.) has greatly expanded our impact. The value of working with CPP is clear: faster recoveries, reduced losses, and a stronger safeguard for contractors statewide.”

– Captain Anthon Easter, Taskforce for Regional Autotheft Prevention (T.R.A.P.)

Founded in 1980, CPP has grown into the leading theftprevention organization serving the construction industry in Southern California.

• CPP’s mission is “to protect our members’ assets from theft and fraud” by acting as a liaison with law-enforcement partners and offering proven prevention methods.

• To date, CPP has assisted in the recovery of more than $57 million in stolen equipment value.

Key services include:

▸ Customizable “layers of protection” for jobsites and equipment.

▸ Coordination with local and regional law enforcement (including the National Insurance Crime Bureau) and direct notification systems to more than 300 contacts in the database when theft occurs.

▸ A 24-hour reward hotline for stolen equipment.

▸ Report verification for stolen equipment.

▸ Training, seminars, decals, signage, and other marking tools to help raise awareness and protect assets.

Enrollment in CPP is straightforward and designed for construction-industry companies (contractors, rental firms, equipment owners) and any industry that supports them.

Here’s a breakdown:

1. Visit the “Become a Member” section on CPP’s website.

2. Fill out a membership application

3. Upon payment and signup:

▸ Members receive immediate access to support resources, Theft Alert bulletins, report verification, and entry into CPP’s database.

▸ Members can order supplies (reward hotline decals, signage, marking tools) via the CPP “Order Supplies” portal.

▸ Members benefit from group training, incidentreport support, and lawenforcement coordination.

4. CPP also offers a “Partner Program” for companies seeking greater visibility and marketing benefits; this is listed alongside the standard member application.

Somers emphasizes that, “What you put into it is what you get out of it. Getting more deeply involved by attending our Board of Directors

meetings allows for invaluable exposure to a think tank of likeminded professionals in the construction industry and law enforcement discussing theft metrics, prevention tactics.”

Somers also says that prevention requires effort from all sides- contractors, rental and equipment companies, and law enforcement alike.

“We need to stop viewing theft as just part of doing business,” she says. “With thefts up nearly 200%, we can’t afford that mindset anymore. If everyone layers their defenses and stays alert, we can make it much harder for these criminals to operate.”

For more information or to become a member of CPP, visit cppsocal.org or call CPP at (562) 860-9006. Cc

PC55MR-5 SMALL EXCAVATORS

Komatsu small excavators feature advanced technology for maximum e ciency, improved productivity, lower fuel consumption. They o er reliable performance, excellent forward visibility, and a comfortable operator workspace. Experience power, precision, and comfort with this model.

A trusted leader in intelligent machine control design, the updated, factory-integrated system minimizes over-excavation and empowers operators to dig straight to grade, faster with greater accuracy.

Large high-strength steel castings on the boom, arm and bucket link.

Closed-center load-sensing hydraulics for precise, fine control.

Large displacement high-e ciency pumps provide optimal attachment flow.

Large, spacious, quiet cab featuring standard air suspension seat.

For versatility and high production consider the PC360LC-11 large excavator - it combines bucket capacity up to 2.56 yd3 and excellent power with dimensions making it transportable.

Large high-strength steel castings on the boom, arm and bucket link

Closed-center load-sensing hydraulics for precise, fine control

Large displacement high-e ciency pumps provide optimal attachment flow

Large, spacious, quiet cab featuring standard air suspension seat

Performance and versatility in a compact hydraulic excavator

SoCal JCB officially opened its new Colton headquarters at 2860 S. Iowa Ave. with a ribbon-cutting ceremony on Wednesday, November 19, followed by an afternoon open house. Guests enjoyed facility tours, lunch, equipment displays, and a special appearance by the JCB

monster truck DIGatron, giving attendees an up-close look at one of JCB’s most iconic machines. The event brought together customers, partners, and the local community, offering an opportunity to meet the SoCal JCB team, explore the latest JCB equipment, and experience firsthand how

power, performance, and innovation come together under one roof.

More than an open house, the celebration marked the beginning of an exciting new chapter for JCB in Southern California. Cc

Customers and employees mingled in a relaxed, welcoming atmosphere filled with tours, food, and plenty of camaraderie.

Facility photos highlighted the shop bays, reception area, and other key spaces throughout the new Colton headquarters.

PURCHASE or RENT EQUIPMENT

St ow & Go Jib W inc h

Stows in plat for m and requires no as sembly. 50 0 lb. capacit y in all posit ions eliminates gues swork

180 Degree Platform Rotation

Maximizes acces s for each set up.

Heav y Dut y Structural Components

Robust subf rame, t ur ret, bear ing, out r iggers and boom for smoot h r ide and except ionally long usef ul life.

Main Boom Material Handling

2,00 0 lb capacit y for added f unc t ionalit y

• 87’ Wor king height, 7 7’ side reach on 25,999 lb. chas sis

• Mater ial handling on main boom and in wor k plat for m

• 30” x 54” E ZR wor k plat for m wit h 750 lb capacit y

• 180 Degree plat for m rotat ion

• Full lengt h steel subf rame for excellent stabilit y and long chas sis life