4 minute read

The Wholesaler's Assets and Investment in the lndustry

This is the third in a series o/' articles about the./brest products wholesaler o.f 1979. Material ./br these articles comes ./rom NAWLA sales surveys o.l' its 'membership,./rom the NA WLA Per./brmance Analysis Program andJrom the NAWLA "Observotion & Expectation" Report.

I N THE "good old days" of I wholesaling forest products. there was some truth to the adage of "Print some letterheads, rent a desk, put in a phone and you are a wholesaler." It's not that simple in today's marketing environment. It takes assets. investment and people to market product. People have always been a necessary ingredient of wholesale distribution. However, today those needed people are required to be better managers and possess sophisticated skills as never before.

Forest products wholesalers are meeting this marketing challenge on a number of fronts. Within the NAWLA wholesaler membership of 426 companies, there was an investment of nearly 100 million dollars in 1978 for added or expanded facilities and personnel. Our survey of wholesaler assets that same year indicated that these people passed the one billion dollar mark. These asset figures do not include the inventory and receivables "investment" of over 900 million dollars on a daily basis that are always part of the wholesaler's function.

Pretty impressive dollar figures. It enables wholesaler-distributors to better serve both their suppliers and customers. Suppliers desire and look for distributors who maintain substantial businesses that have the wherewithal to inventory, to introduce new products, and/or sell the "complete line."

Even in wholesale soecialization.

there is a requirement for assets and sophisticated marketing. At the same time, many customers rely more and more on ready access to local inventory for immediate shipment. To fulfill this need, over 200 NAWLA wholesaler companies offer distribution center services from over 400 locations.

These ever-growing service facilities and investments in industry product distribution would be meaningless without the people to "make things happen."

While customers and suppliers normally interface with just salesmen and buyers, each of these "specialists" are backed up by two other wholesale employees. These back-up people in administration, in warehouse personnel, in money management, are, by necessity, high trained people.

A case in point that illustrates the needs of today is the recently completed NAWLA survey on vehicle use, fuel consumption and transportation. Our members were surveyed under the auspices of the National Association of Wholesalers and NAWLA now has a profile on automobile use. truck

(Please turn to page 73)

..THERE'S MORE THAN A MARGIN IN A WHOLESALER'S MARGIN OF A NAWLA DISTRIBUTION MARGIN!''

This parody of a famous fast food franchiser jingle emphasizes the fact that today's marketing requires much more than a salesman's fee for selling a product. Marketing is a distribution service in an economy fast becoming service-oriented.

Independent wholesalers are meeting this challenge of change. today and tomorrow.

IT TAKES ASSETS. The total assets of the 426 wholesaler members of North American Wholesale Lumber Association exceeded 1 billion dollars in 1978. lt is their contribution to the forest products industry as its primary distribution arm.

lT TAKES FACILITIES. Half of the NAWLA wholesaler members offer distribution center services from over 400 locations.

Nearly 60 NAWLA wholesalers operate reload centers.

Approximately 85 NAWLA wholesalers have remanufacturing capability.

lT TAKES PERSOMVEL. Independent NAWLA wholesaler members have a sales force of 3,875. lt takes another 8,352 people in executive, administrative and support capacities.

The movement of product, the service of distribution and the financial investment and support is the wholesaler function. A function which must be supported by somebody.

Forest Facts for Dealers

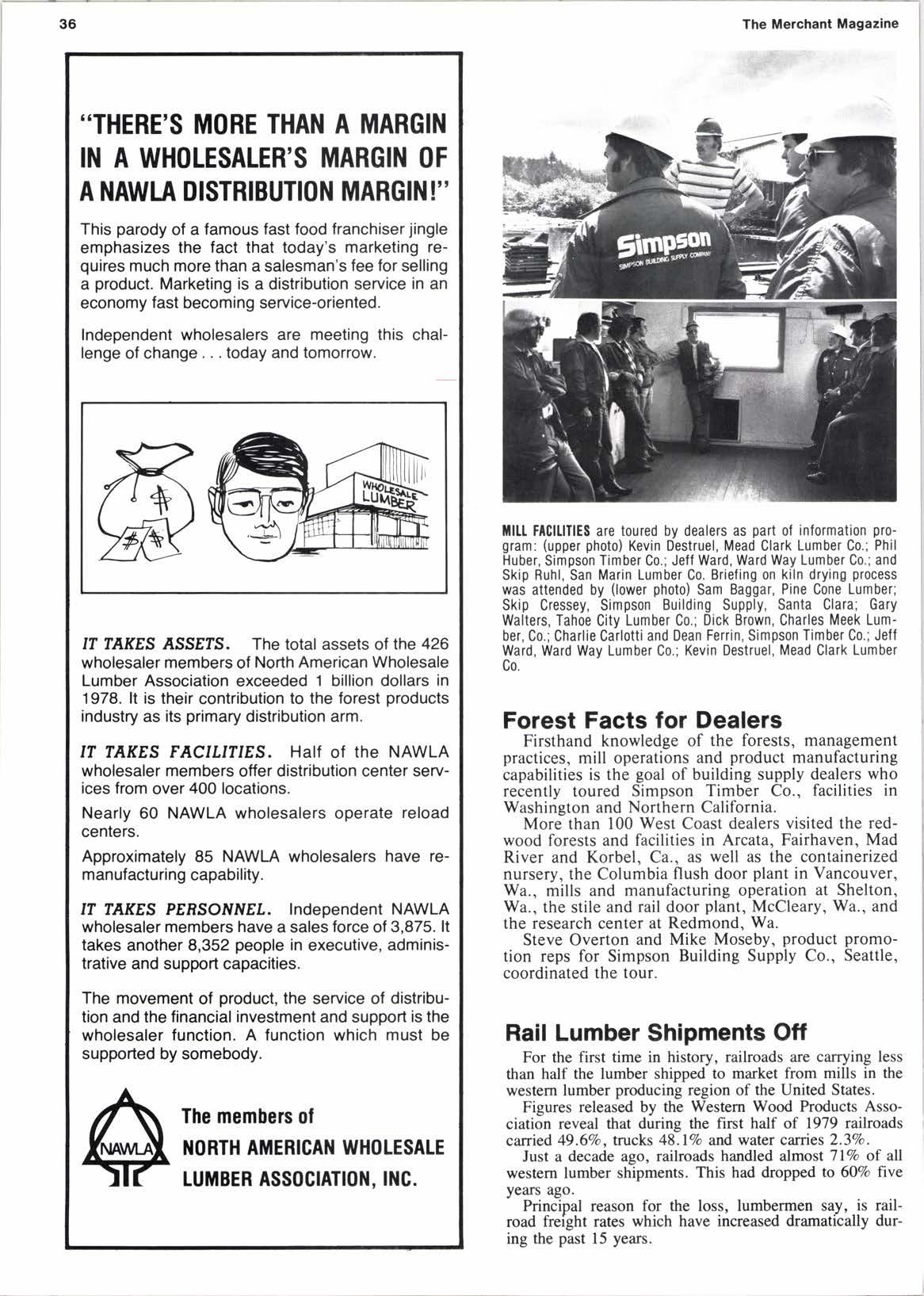

Firsthand knowledge of the forests, management practices, mill operations and product manufacturing capabilities is the goal of building supply dealers who recently toured Simpson Timber Co., facilities in Washington and Northern California.

More than 100 West Coast dealers visited the redwood forests and facilities in Arcata, Fairhaven, Mad River and Korbel, Ca., as well as the containerized nursery, the Columbia flush door plant in Vancouver, Wa., mills and manufacturing operation at Shelton, Wa., the stile and rail door plant, McCleary, Wa., and the research center at Redmond, Wa.

Steve Overton and Mike Moseby, product promotion reps for Simpson Building Supply Co., Seattle, coordinated the tour.

Rail LumberShipmentsOff

For the first time in history, railroads are carrying less than half the lumber shipped to market from mills in the westem lumber producing region of the United States.

Figures released by the Westem Wood Products Association reveal that during the first half of 1979 railroads carried 49.6Vo, trucks 48. l%o and water caries 2.3Vo.

Just a decade ago, railroads handled almost TlVo of all western lumber shipments. This had dropped to 60Vo five years ago.

Principal road freight ing the past reason for the loss, lumbermen say, is railrates which have increased dramaticallv durl5 years. ll, ITH THE increasing battle for lU a larger share of the wood products market, the pressure treaters in the Western states are engaged in an aggressive campaign to grab their share with treated lumber, posts, and poles for residential and com. mercial uses.

One of the biggest names in wood preserving in the West is McFarland Cascade, a member of the American Wood Preservers Institute, with facilities in four western states and Canada. The offspring of two pioneer firms, Idaho Pole founded by L.D. McFarland in Sandpoint, Id., in 1916, and Cascade Pole which began in 1936 on the Tacoma, Wa., tideflats, the firm operates five treating plants, six peeling and storage yards, and a sawmill.

Treatment plants at Sandpoint, Id., Bozeman, Mt., Eugene, Or., and Tacoma and Olympia, Wa., have facilities for handling lumber, timber, plywood, and poles. Penta, creosote, and water-borne salts treatments are possible with the addition, recently, of Wolman Salts (CCA-C) at the Tacoma plant.

According to Robert C. McBride, manager of sales, lumber, McFarland Cascade is now a