7 minute read

ON

"With the price of gasoline these days, I want to be sure I'm getting my money's worth from every tankful. So I'm doing four simple things to save gas-and it's like getting a 156 discount on every gallon!

"Just slowing down from 70 to 55 mph on the highway saves enough gas to equal a 69 a gallon discount. Keeping my car tuned saves 40 a gallon more. And I'm saving another nickel a gallon just by using radial tires and keeping them correctly inflated.

"That's like getting an extra $3.00 worth from every tank of gas-and 50 more miles!"

Saving energy is easier than you think, and with the rising energy costs we're facing today-as consumers, and as a nation-it's never been more important.To get a free booklet with more energy-saving tips, write "Energy," Box 62, Oak Ridge, TN 37830 or mail the coup0n.

M EN DEN HALL exec ut ive vice president Lumber Merchants Association of Northern California

A S MAJOR corporations such as ;{ tsoise-Cascadc and Weyerhacuser open new retail opcrations. the small rndcpcndr'nt rctirilcr sees the urgcnt need to rmprclve thc professional abilities of his sales stalT.

f nrollment in thc lssocilrtion correspondence courses, Product Knowledgc ancl Selling Skills. is showing ii great increase. Calls lionr dealers asking when the nexl sellirrg skills workshop will be conductecl is a strong indication that dealers have a genuine conccrn. More and more dealers are calling employec meetings on a scheduled basis to add to their sclling skills and product knowledge.

Recent tleld visits have brought comments fronr dealers that a priority must be place d on employee training. We have made an attcmpt to analyzc the reason for this rcnewed interest. It appears that retailers havc a great pressure placed upon them to hold down the runrway prices of merchandise while their costs of operation are increasinB: their nccd to increase wagcs und salaries and employee benefits are also rising. Improving the efficiency of operations is taking place to assist in holding down merchandise prices as contpetition becomes keen.

Another techniquc that retailers have determined to be efl'ective in holding down the price of merchandisc is irrcreasing individual cmploy'ee productivity. Employee pay and benel'its account for a high perccntage of total operating costs. If each enrployee can improve productivity by even 5(1,. company profits will increase and a tighter line can be held on merchandise pricing. A great number of'dealers are now placing emphasis on the return on investment in the employee, just as they have, in the past. placed considerable attention on their ove rall relurn on investment.

During visits to retail operations we have seen the increased return on employ'ee investment by those firms who have been leaders in developing this area. lt did take timc. lt did require sending employees to training seminars. It did requirc giving incentives to employees for contpletion ol correspondence courses. lt did require providing employees with benefits to makc them want to work for the company and to produce, but it did bring results.

The return for all of this investment has been higher sales per employec, a better employee attitude toward the customer, a better company image, and more professionalism in the employee because he has acquired more product knowledge and better selling skills.

This trend of interest in the employee seems to be sweeping through the No. Ca. retail firms. There is no doubt that dealers know whal must be done and have reached the point of doing it to insure that they are in there fighting with the best.

Make Big Jobs Easy

The big job is easy to handle when it becomes a number of small jobs.

First, divide the work into steps with goals which can be reached in short, measured time spans. Then detail each step includine an estimate of the time involved to completd with a deldline date.

If necessary, assign each portion of the job to a different worker.

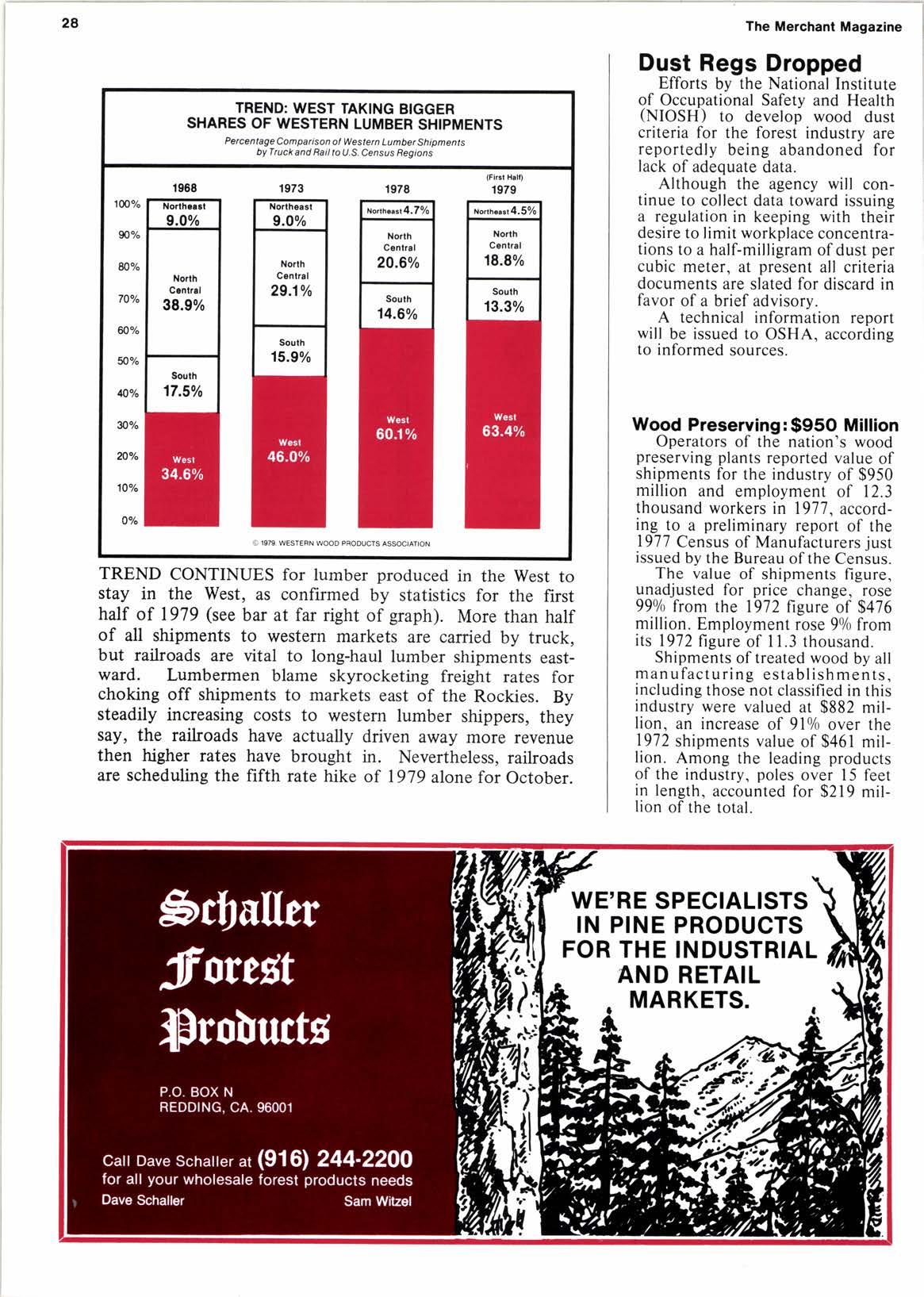

TREND CONTINUES for lumber produced in the West to stay in the West, as confirmed by statistics for the first half of 1979 (see bar at far right of graph). More than half of all shipments to western markets are carried by truck, but railroads are vital to long-haul lumber shipments east- ward. Lumbermen blame skyrocketing freight rates for choking off shipments to markets east of the Rockies. By steadily increasing costs to western lumber shippers, they say, the railroads have actually driven away more revenue then higher rates have brought in. Nevertheless, railroads are scheduling the fifth rate hike of 1979 alone for October.

Dust Regs Dropped

Efforts by the National Institute of Occupational Safety and Health (NIOSH) to develop wood dust criteria for the forest industry are reportedly being abandoned for lack of adequate data.

Although the agency will continue to collect data toward issuing a regulation in keeping with their desire to limit workplace concentrations to a half-milligram of dust per cubic meter, at present all criteria documents are slated for discard in favor of a brief advisory.

A technical information report will be issued to OSHA, according to informed sources.

Wood Preserving: $95O Million

Operators of the nation's wood preserving plants reported value of shipments for the industry of $950 million and employment of 12.3 thousand workers in 1977. according to a preliminary report of the 1977 Census of Manufacturers just issued by the Bureau of the Census. The value of shipments figure, unadjusted for price change, rose 990/o from the 1972 figure of $476 million. Employment rose 90/o from its 1972 figure of ll.3 thousand.

Shipments of treated wood by all manufacturing establishments, including those not classified in this industry were valued at $882 million, an increase of 9lolo over the 1972 shipments value of $461 million. Among the leading products of the industry, poles over l5 feet in length, accounted for $219 million of the total.

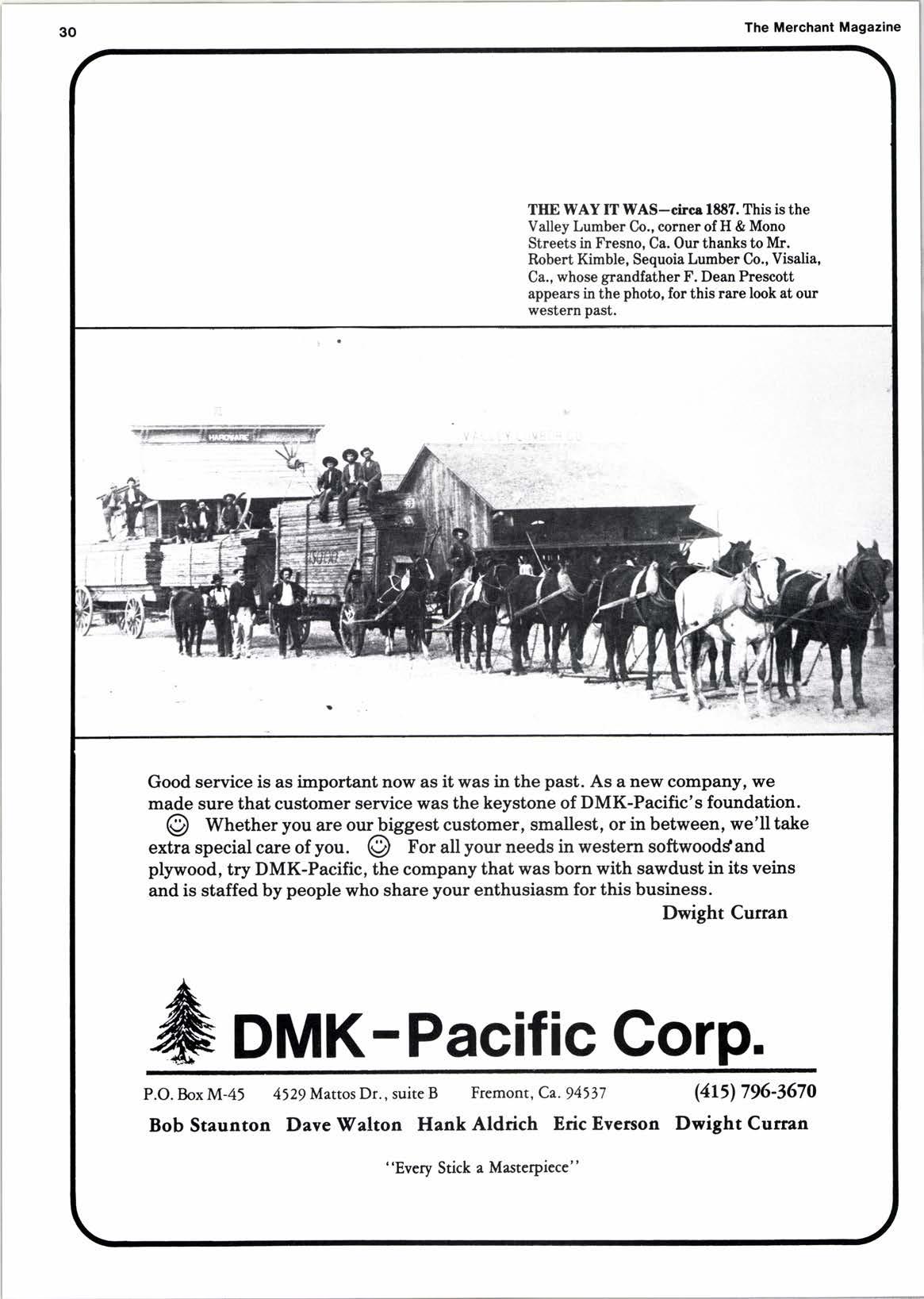

TIIE WAY fT WAS-circa 1EE7. This is the Valley Lumber C,o., corner of H & Mono Streets in Fresno, Ca. Our thanks to I\[r. Robert Kimble, Sequoia Lumber Co., Visalia, Ca., whose grandfather F. Dean Prescott appears in the photo, for this rare look at our western past.

Good service is as important now as it was in the past. As a new company, we made sure that customer service was the keystone of DMK-Pacific's foundation.

O Whether you are our biggest customer, smallest, or in between, we'll take extra special care of you. () For all your needs in western softwooddand plywood, try DMK-Pacific, the company that was born with sawdust in its veins and is staffed by people who share your enthusiasm for this business.

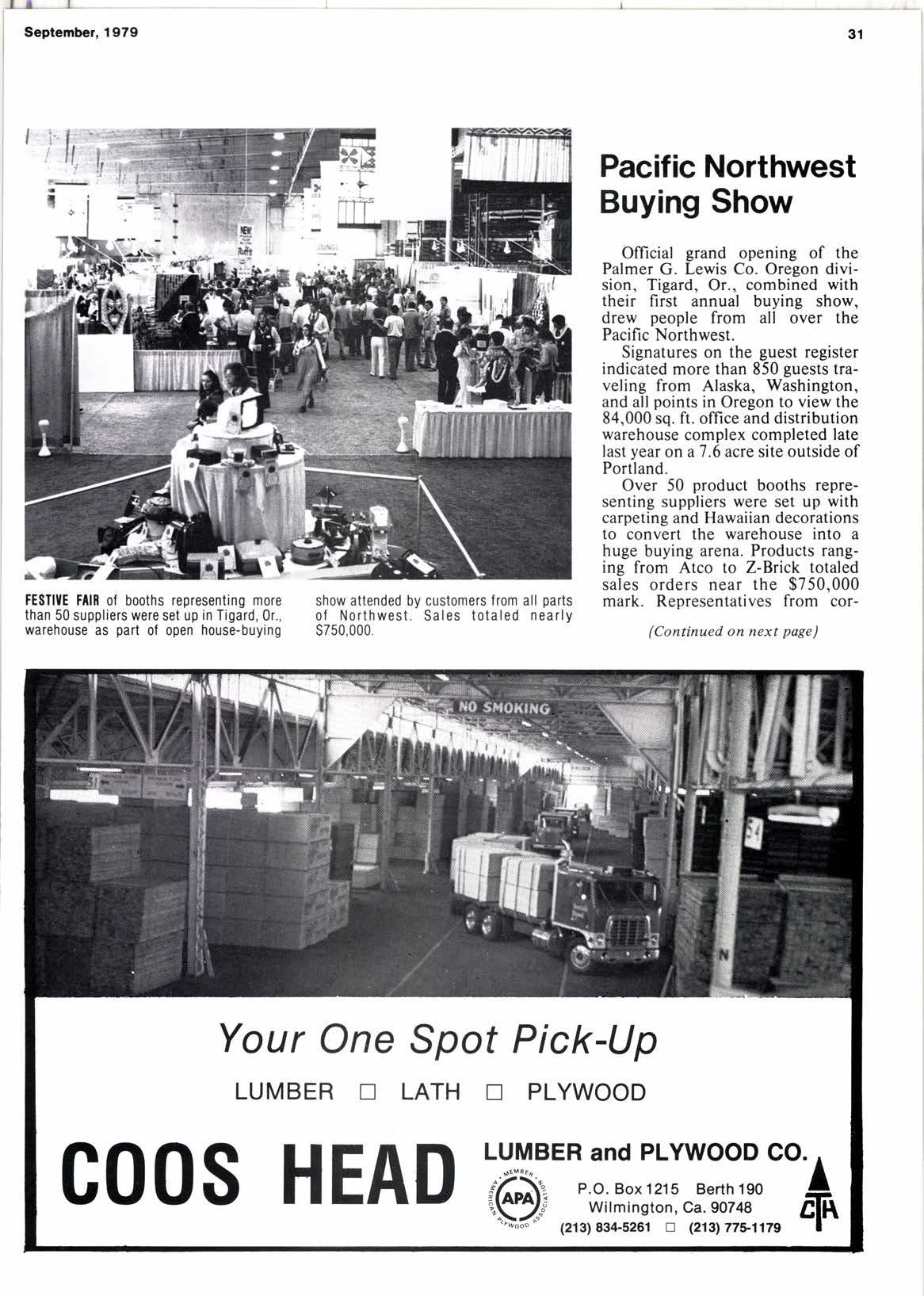

Pacific Northwest Buying Show

Oflicial grand opening of the Palmer G. Lewis Co. Oregon division, Tigard, Or., combined with their first annual buying show, drew people from all over the Pacific Northwest.

Signatures on the guest register indicated more than 850 guests traveling from Alaska, Washington, and all points in Oregon to view the 84,000 sq. ft. office and distribution warehouse complex completed late last year on a 7.6 acre site outside of Portland.

Over 50 product booths representing suppliers were set up with carpeting and Hawaiian decorations to convert the warehouse into a huge buying arena. Products ranging from Atco to Z-Brick totaled sales orders near the $750,000 mark. Representatives from cor-

(Continued on next page) lllTllilS TllE lllll on the head, Gordon Steffens, sales mgr. for Morrison Steel & Wire, Ltd., Vancouver,8.C., (left, upper photo) completes a transaction with the aid of J. Cutler Lewis. Palmer G. Lewis Co. exec. v.p., at PGL open house-first annual buying show at Tigard, 0r., division. Ansel and Frances Hyland of Eugene Planing Mill (lower photo) were among 850 attending.

Northwest Show

(Continued from previous page) porate headquarters were on hand to assist local sales reps.

In line with the island theme was a drawing for a week in Hawaii for two. Other drawings awarded merchandise prizes. A l-uau style dinner was served.

Wlckes Wlll Fight Recesslon

Wickes Corp. has initiated a hard-hitting campaign to counteract the economic slow down expected during the remainder of 1979.

E.L. McNeely, chairman and chief executive officer, of the world's largest distributor of building materials, observes, "There's little disagreement that the economic picture is about to worsen. The real question is how are we going to address the problem."

"The goal of our attack is to gain a bigger share of the market," he added. "This applies most significantly to our Lumber Division."

It will aim for a larger market share by offering a broader line of building and home remodeling products, marketing these products aggressively, instituting more com- petitive pricing. and tmprove servlce, McNeely. continuing to according to

Wickes Lumber currently operates 272lumber centers with 1979 sales expected to top $l billion. The division expects to have 400 stores and sales of $2.5 billion by 1984, according to Paul Hylbert, general manager of the division.

How to Beat a Sales Slump

Sales on the decline for a usually aggressive, productive salesman? Try one or more of these suggestions to get him back on the track.

o If he has the knack for management and paperwork, move him to an inside job.

o Spark his interest with a special market or products study; combine it with his usual selling responsibilities.

o Challenge him with a tough account, one of the company's biggest buyers, or a brand new territory to work.

o Ask him what would make the job more dynamic; maybe he is just bored.'

Palco to BuyBrooks-Scanlon

The Pacific Lumber Co. and Brooks-Scanlon, Inc. have announced that agreement in principle has been reached for Pacific to acquire Brooks-Scanlon by means of a merger.

If consummated, each share of Brooks-Scanlon stock will be exchanged for .82 shares of Pacific common stock. Brooks-Scanlon presently has 2,144,000 shares outstanding; Pacific presently has approximately 12,040,000 shares of common stock outstanding.

The merger is subject to negotiation and execution of a merger agreement and approval by the boards of directors of both companies, the shareholders of Brooks-Scanlon and various governmental agencies. Pacific expects to account for the acquisition as a purchase.

Through its forest products operations, Pacific is a major producer of redwood lumber and other forest products. In addition, through its subsidiaries, Pacific is a leading manufacturer of acetylene gas and plasma cutting and welding equipment, industrial gas cylinders and fluid power products. For the six-month period ended June 30, 1979, Pacific reported revenues of $123.3 million and net income of $24.2 million.

Brooks-Scanlon, headquartered in Bend, Or., is engaged primarily in the forest products business. It owns and manages 235,000 acres of timberland in central Oregon, manufactures a wide line of ponderosa pine lumber, fir plywood and other wood proilucts. Brooks-scanlon had revenues of $44 million and net income of $4.6 million for the first six months of this vear.

12 ACRES 0F SELF-C0ilTAtltED C0I{S0LIDATI0N, STORAGE, TRUCKII{G, iIAl{UFACTURIiIG, AI{D WH0LESALE l)lSTRlBUTl0tl FACILITIES o 24 YEARS

0F GR0WIH Al{D EXPAI{S|0i{ . PR0FESSIOIIALS lN

CEOAR SPECIALTY lTEt[S FAST RESP0i{SE o FLEXIELE MA}IUFACTURII{G AilD SALES POLICY o 1r2, 1r3, 2t2,2r3 - C0Mil0t{ At{O CLEAR, GREEN. SURFACED A1{O/l)R R(lUGH

CEDAR M0UL0lt{G ST0CK - TIGHT Kt{07

ANO CLEAR o FENCII{G BOAROS. GRAPE STAKE TYPE

PALII{GS BENDER B|)ARDS o GARDEI{ ilUBSERY. OEALER. INDUSTRIAL

ITEMS

I RANl)l)M WIDTH AID THICKNESS ROUGH

GREEl{ BARl{BOAROS