2 minute read

A visit to the no. 1 pallet manufacturer

J

F Vou spend more than 30 ^ years building up a business from scratch in a highly competitive field to the point where the firm is the largest of its kind in the world, it is only natural to expect to pause, throttle back a touch and relax, right?

Wrong.

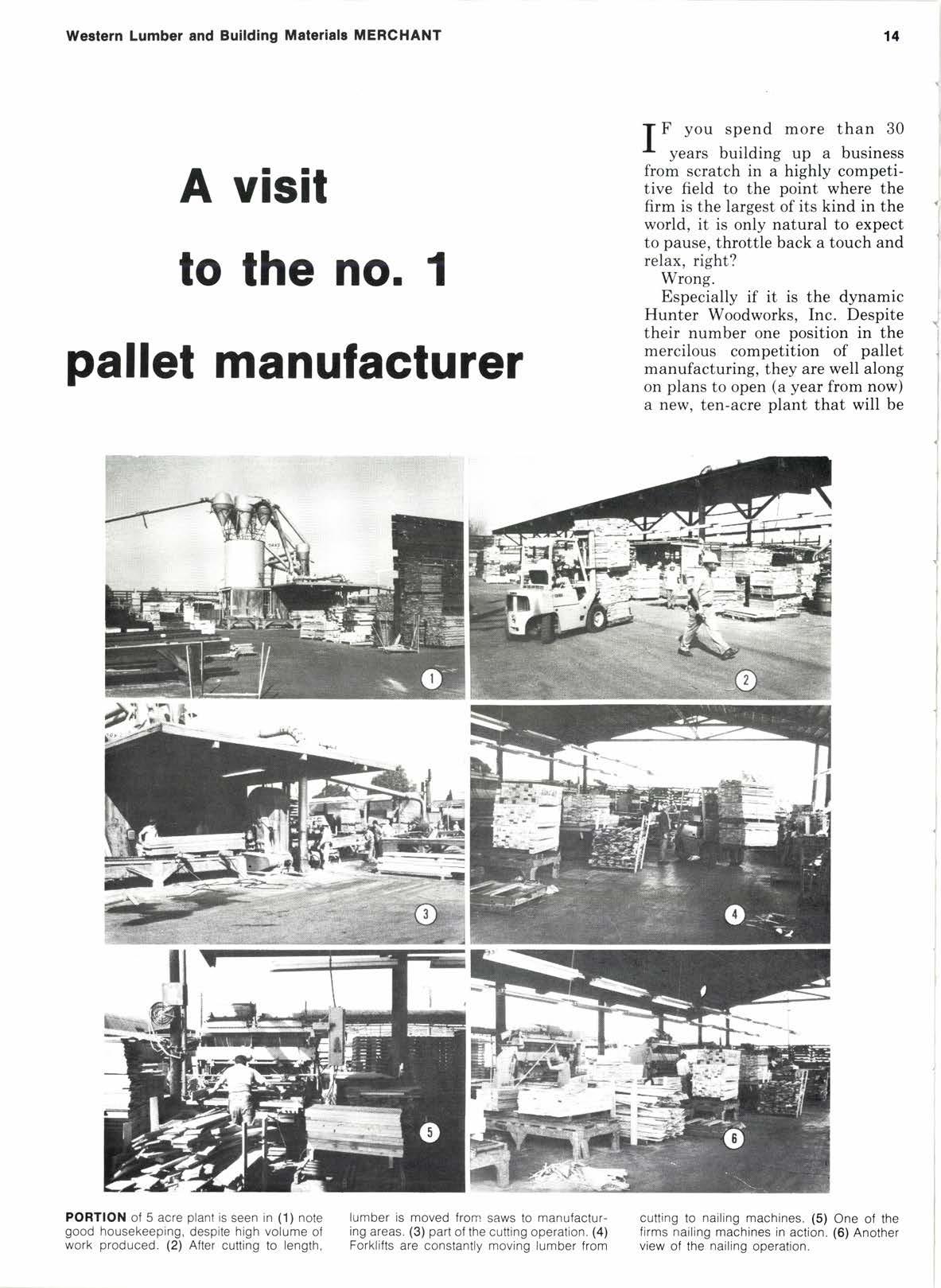

Especially if it is the dynamic Hunter Woodworks, Inc. Despite their number one position in the mercilous competition of pallet manufacturing, they are well along on plans to open (a year from now) a new, ten-acre plant that will be an addition to their present, bustling five-acre facility in Carson, Ca.

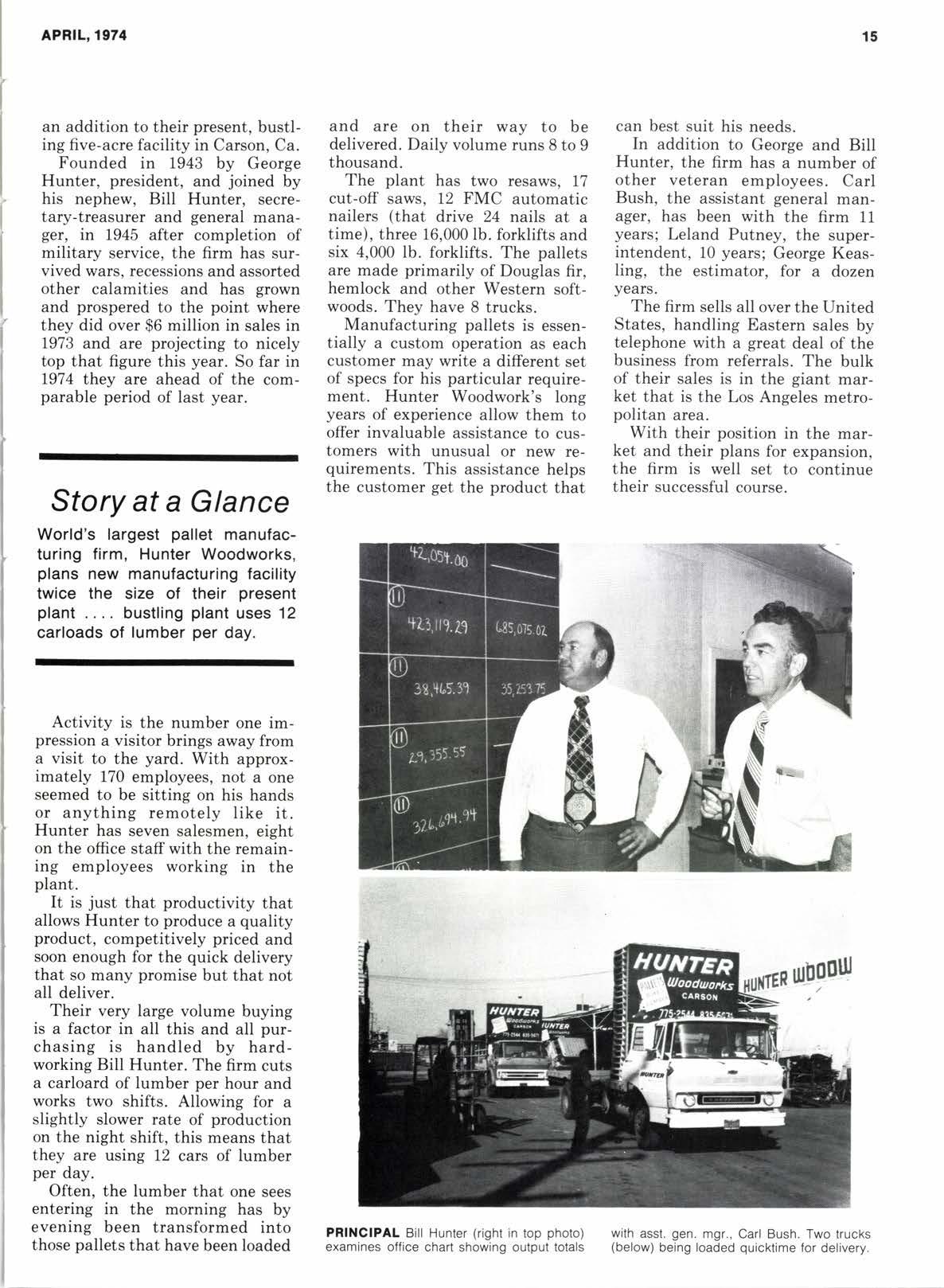

Founded in 1943 by George Hunter, president, and joined by his nephew, Bill Hunter, secretary-treasurer and general manager, in 1945 after completion of military service, the firm has survived wars, recessions and assorted other calamities and has grown and prospered to the point where they did over $6 million in sales in 1973 and are projecting to nicely top that figure this year. So far in 1974 they are ahead of the comparable period of last year.

Story at a Glance

World's largest pallet manufacturing firm, Hunter Woodworks, plans new manufacturing facility twice the size of their present plant .... bustling plant uses 12 carloads of lumber per day.

and are on their way to be delivered. Daily volume runs 8 to 9 thousand.

The plant has two resaws, 17 cut-off saws, 12 FMC automatic nailers (that drive 24 nails at a time), three 16,000 lb. forklifts and six 4,000 lb. forklifts. The pallets are made primarily of Douglas fir, hemlock and other Western softwoods. They have 8 trucks.

Manufacturing pallets is essentially a custom operation as each customer may write a different set of specs for his particular requirement. Hunter Woodwork's long years of experience allow them to offer invaluable assistance to customers with unusual or new requirements. This assistance helps the customer get the product that can best suit his needs.

In addition to George and Bill Hunter, the firm has a number of other veteran employees. Carl Bush, the assistant general manager, has been with the firm 11 years; Leland Putney, the superintendent, 10 years; George Keasling, the estimator, for a dozen years.

The firm sells all over the United States, handling Eastern sales by telephone with a great deal of the business from referrals. The bulk of their sales is in the giant market that is the Los Angeles metropolitan area.

With their position in the market and their plans for expansion, the firm is well set to continue their successful course.

Activity is the number one impression a visitor brings away from a visit to the yard. With approximately 170 employees, not a one seemed to be sitting on his hands or anything remotely like it. Hunter has seven salesmen, eight on the office staff with the remaining employees working in the plant.

It is just that productivity that allows Hunter to produce a quality product, competitively priced and soon enough for the quick delivery that so many promise but that not all deliver.

Their very large volume buying is a factor in all this and all purchasing is handled by hardworking Bill Hunter. The firm cuts a carloard of lumber per hour and works two shifts. Allowing for a slightly slower rate of production on the night shift, this means that they are using 12 cars of lumber per day.

Often, the lumber that one sees entering in the morning has by evening been transformed into those pallets that have been loaded