A portfolio of Clean Label ingredients that retain the freshness of all your baked goods, naturally. Leading the industry with the only Natural Verified Mold Inhibitors.

It’s where we began. For the past century, Brolite has created a variety of naturally fermented cultured flavors. Designed to give bakers a handcrafted taste in no time, these flavors are a great addition to any formula.

Our sours range from strong and pungent to sublte and delicate flavors giving the baker an exact flavor profile needed. Brolite ferments various flours for specific amounts of time, then dehydrates the custom flavor before it is finally milled into a fine, easily handled, free-flowing powder.

Unique artisan flavors made easy for any baker and any baking application.

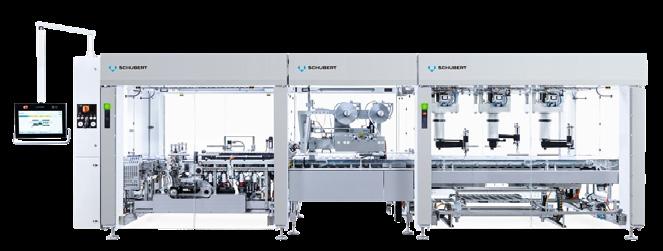

www.intralox.com

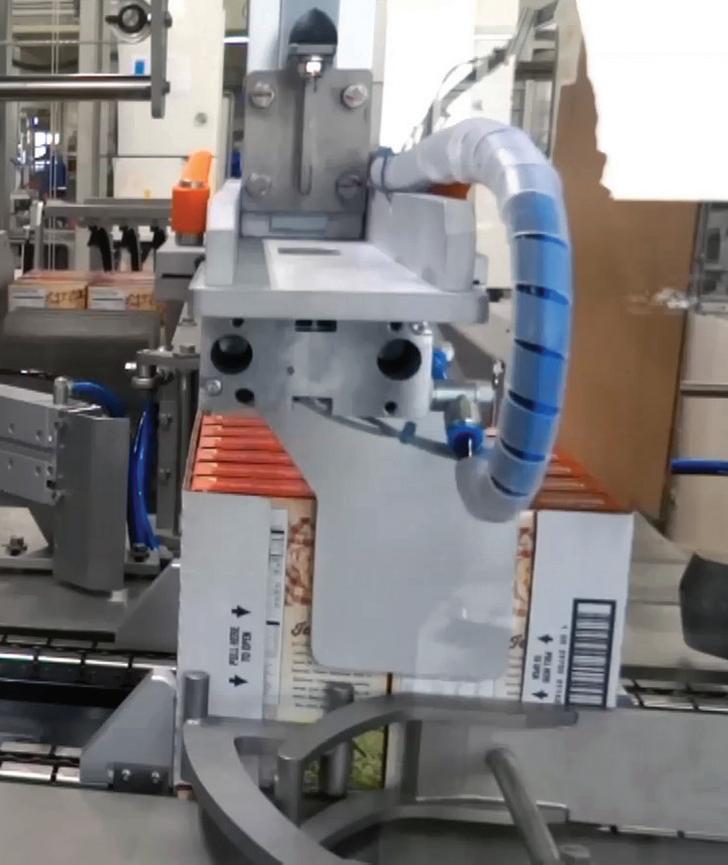

Intralox’s new Active Integrated Motion (AIM) Glide™ is a gentle, hygienic automation solution. It eliminates unscheduled downtime and jams while requiring 75% less maintenance and 50% less cleaning time than metal slat switches.

Gentle product handling while maintaining orientation

75% less maintenance

Reliable zero-jam automation

50% less cleaning time

Zero lubrication required

Paul Lattan

President - Principal

Steve Berne

Executive Vice President - Principal

Joanie Spencer

Vice President - Partner

Paul Lattan

Publisher | paul@avantfoodmedia.com

816.585.5030

Steve Berne

Director of Sales | steve@avantfoodmedia.com

816.605.5037

Erin Zielsdorf

Account Executive | erin@avantfoodmedia.com

937.418.5557

Joanie Spencer

Editor-in-Chief | joanie@avantfoodmedia.com

913.777.8874

Mari Rydings

Editorial Director | mari@avantfoodmedia.com

Jordan Winter

Creative Director | jordan@avantfoodmedia.com

Olivia Siddall

Multimedia Director | olivia@avantfoodmedia.com

Annie Hollon

Digital Editor | annie@avantfoodmedia.com

Maddie Lambert

Associate Editor | maddie@avantfoodmedia.com

Lily Cota

Associate Editor | lily@avantfoodmedia.com

Beth Day | Maggie Glisan

Contributors | info@commercialbaking.com

Society of Baking

Commercial Baking is published by Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108. Commercial Baking considers its sources reliable and verifies as much data as possible, although reporting inaccuracies can occur. Consequently, readers using this information do so at their own risk. Commercial Baking is distributed with the understanding that the publisher is not liable for errors and omissions. Although persons and companies mentioned herein are believed to be reputable, neither Avant Food Media nor any of its employees accept any responsibility whatsoever for their activities. Commercial Baking magazine is printed in the USA and all rights are reserved.

No part of this magazine may be reproduced or transmitted in any form or by any means without written permission of the publisher. All contributed content and advertiser supplied information will be treated as unconditionally assigned for publication, copyright purposes and use in any publication or digital product and are subject to Commercial Baking ’s right to edit.

Commercial Baking ISSN 2767-5319, / USPS Publication Number: 25350 is published in February, April, June, July, August, October and December, in print and digital formats by Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108. Periodicals Postage Paid at Kansas City, MO, POSTMASTER: Send address changes to Commercial Baking, c/o Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108.

Circulation is tightly controlled, with print issues sent only to hand-verified industry decision makers and influencers. To apply for a free subscription, please visit www.commercialbaking.com/subscription

At the Puratos Industrial Pilot Bakery — Powered by AMF — global inspiration meets end-to-end innovation. During your visit, you gain access to deep consumer insights and collaborate directlywithPuratos&AMFteams—includingbakers,ingredient experts, and specialists in best-in-class automation solutions — to refine formulations and optimize recipes. Then you test your product for scalability in a real-world production environment without disrupting your current operations.

Complete your globally inspired creations with on-site consumer validation — accelerating your path to market with confidence and speed. Schedule your visit to bring your next breakthrough to life.

2 IN 3 CONSUMERS WANT TO TRY FOODS FROM AROUND THE WORLD

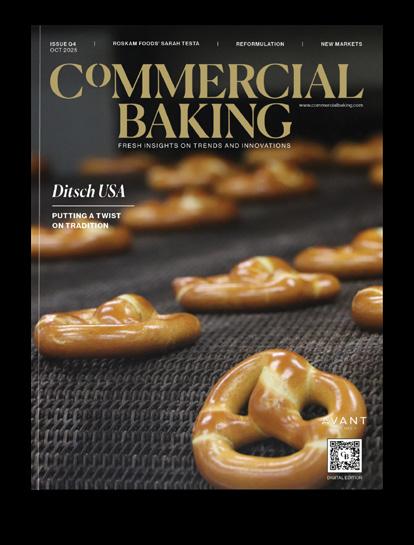

PLUS: Look for QR codes that contain exclusive digital content throughout the issue.

Association Roundup: One Big Year

Servant leaders for ABA, ASB and BEMA take stock of the ups, downs and big opportunities.

75 Industry Trends: Tariffs

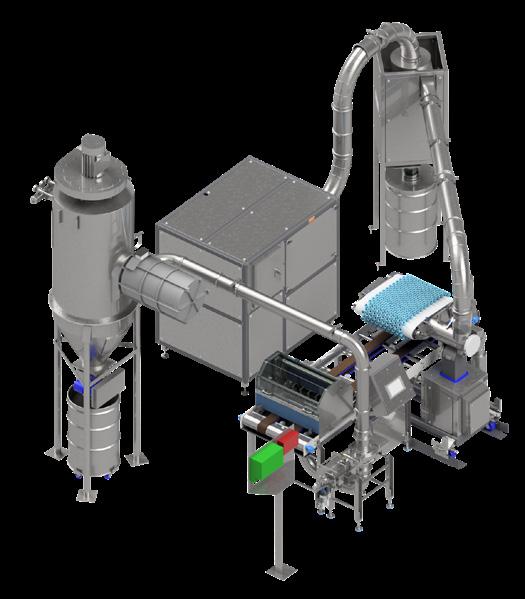

Consistent flow for sticky powders, fibers, and pellets.

The NX feeder is built with a negativeangled trough that keeps even the most challenging ingredients moving.

From fine flours to sticky dough bases, its design minimizes buildup for consistent, precise flow - ideal for difficult, poor-flowing powders.

Choose a system engineered for reliability and a partner that knows the nuances of your process.

Learn more about the NX Feeder. sales@kubota-btca.com

Coperion unites the leading technology brands in food manufacturing to deliver innovative system solutions for your bakery.

Technology for: Systems & Ingredient Automation

Fermentation, Mixing, Dividing, Forming, Depositing & Baking

Decorating & Cutting E:

� baker perkins b bakon � diosna �operion

@ peerless $ shaffer � shick esteve

Scan the QR code to find out more

kemutec lUJ unifiller •4 vmi

JOANIE SPENCER Editor-in-Chief | joanie@avantfoodmedia.com

WATCH NOW:

Joanie Spencer reflects on how the industry adapted to the year’s “big impact” issues and looks ahead to 2026. Sponsored by Bundy Baking Solutions.

The last issue of the year has me thinking about that phrase. Loosely translated, it means “for old times’ sake” or “times long past.” Was 365 days really that long ago?

Then again, we packed a lot into those three digits. Tariffs. Immigration as it relates to labor. Ultra-processed foods. Two international tradeshows. Tariffs. The longest government shutdown. The impact (and implications) of GLP-1 drugs. AI. The fiber and protein boom. And did I mention tariffs?

With that inventory, I guess topics like generation gaps really can seem like the old days.

I’ve got to hand it to this industry: You know how to adapt. Prior to IBIE, I sat down with the CEOs of the American Bakers Association and BEMA, co-owners of the show. This month, I visited with the board chairs of those two associations, along with the board chair of the American Society of Baking. My key takeaway? The baking industry has a heart of gold and is tough as nails. People have to eat, and over the centuries, bakers and allieds have answered the call, no matter the challenges. In this issue, those board chairs beautifully explain how their members come together to make it happen. It’s not magic … but it sure feels like it.

It may have been a whopper of a year, but as we at Commercial Baking close it out by celebrating innovation — from industry innovators to supplier solutions — it’s time to get energized for the opportunities ahead. So, as you raise a glass to the good, the bad and the auld lang syne of 2025, don’t forget to toast the future.

Commercial Baking checks in on the categories covered in the latter half of 2025.

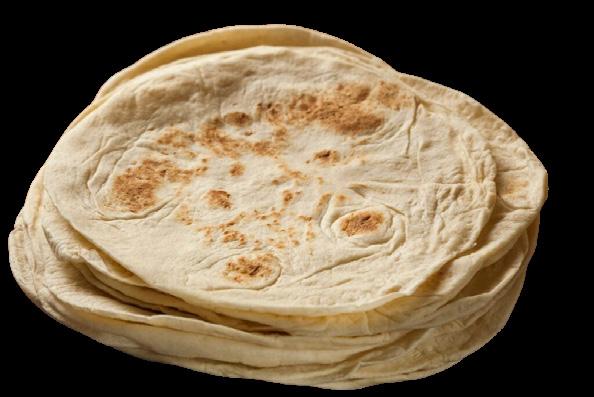

Although unit sales are down vs. a year ago, pita is performing better in the center store than it was in the Q3 report.

Total US Multi-Outlet+ w/ C-Store (Grocery, Drug, Mass Market, Military, Convenience and Select Club, Dollar, Beauty & Online Retailers) | Latest 52 Weeks Ending Oct. 5, 2025

Source: Circana Omnimarket Integrated Fresh, A Chicago-based Market Research Firm (@WeAreCircana)

Store Specialty Cookies Dollar Share*

PRIVATE LABEL: 0.7% SPRITZAL

: 0.2%

BROTHERS

0.2% CHATTANOOGA BAKERY: 8.8 %

With more than 75% of the dollar share, Mondelez International dominates the center store specialty cookie subcategory, maintaining its No. 1 status from the Q3 report.

*Percent rounded to nearest tenth.

Total US Multi-Outlet+ w/ C-Store (Grocery, Drug, Mass Market, Military, Convenience and Select Club, Dollar, Beauty & Online Retailers) | Latest 52 Weeks Ending Oct. 5, 2025

Source: Circana Omnimarket Integrated Fresh, A Chicagobased Market Research Firm (@WeAreCircana)

While unit sales for center store bagels are relatively flat vs. a year ago, a slight dip is visible, as 0.4% growth was reported in October.

Total US Multi-Outlet+ w/ C-Store (Grocery, Drug, Mass Market, Military, Convenience and Select Club, Dollar, Beauty & Online Retailers) | Latest 52 Weeks Ending Oct. 5, 2025

Source: Circana Omnimarket Integrated Fresh, A Chicagobased Market Research Firm (@WeAreCircana)

Center Store vs. Perimeter Bagels

Filled croissants have the strongest dollar sales growth at 20.3% vs. a year ago. However, that growth is 6.5% lower than what was reported in Q4, despite higher dollar sales.

Total US Multi-Outlet+ w/ C-Store (Grocery, Drug, Mass Market, Military, Convenience and Select Club, Dollar, Beauty & Online Retailers) | Latest 52 Weeks Ending Oct. 5, 2025

Source: Circana Omnimarket Integrated Fresh, A Chicagobased Market Research Firm (@WeAreCircana) Perimeter Croissants Dollar Sales

We’re baking up something new!

RoboStack: The next generation of robotic pan stacking

We’re putting the finishing touches on Capway’s latest innovation in bakery automation.

RoboStack ensures the smooth transition of pans as they leave the production line.

RoboStack is designed and built to:

•offer precision handling of multiple pan sizes

•your desired pan stack height

•work with most existing pan carts

•maximize uptime for your production line

Custom engineered conveyor systems allow for the seamless integration of our RoboStack system into your bakery’s existing footprint or new expansion. It all stacks up to the world’s most efficient operation in daily pan logistics.

Call today to be the first in line to have our new RoboStack system installed in your bakery. 877.222.7929

While minimuffins dominate the center store, unit sales are not as strong as they were when reported in October.

Total US Multi-Outlet+ w/ C-Store (Grocery, Drug, Mass Market, Military, Convenience and Select Club, Dollar, Beauty & Online Retailers) | Latest 52 Weeks Ending Oct. 5, 2025

Source: Circana Omnimarket Integrated Fresh, A Chicago-based Market Research Firm (@WeAreCircana)

Center Store Muffins Unit Sales (# in Millions)

Tortillas Dollar Sales

Refrigerated tortillas experienced the biggest dollar sales increase vs. a year ago, sustaining growth as reported in August.

Total US Multi-Outlet+ w/ C-Store (Grocery, Drug, Mass Market, Military, Convenience and Select Club, Dollar, Beauty & Online Retailers) | Latest 52 Weeks Ending Oct. 5, 2025

Source: Circana Omnimarket Integrated Fresh, A Chicago-Based Market Research Firm (@WeAreCircana)

BY MARI RYDINGS

These 13 next-gen leaders are turning up the dial all across the commercial baking industry with their fresh perspectives, creative solutions and genuine enthusiasm for all things baked goods.

They represent every corner of the industry: R&D, food science, quality assurance, human resources, sales, marketing and communications, packaging development, and food safety. Each person brings undeniable passion and expertise to their specific role while also working to solve today’s big-picture challenges, including never-ending labor shortages, evolving consumer behaviors, rapidly changing regulatory compliance and how to attract young talent.

Their willingness to take part in conversations that shape the industry — always asking, “Why?” or “Why not?” — marks them as formidable future leaders. They thrive on collaboration, embrace the use of technology at the bench and on the production floor, and delight in the magical mix of art and science that results in exciting new products.

These are the ones to watch.

The members of this year’s class were selected from submitted nominations and industry recommendations for their leadership qualities, industry involvement and company contributions.

Cheers to the class of 2025!

What does Tarryn see as one of the industry’s biggest challenges?

What year did you join the baking industry, and what led you down this career path?

I come from a long line of amazing home bakers. My first glimpse into the industry happened in 2018 when I worked in the inclusion business. Through those connections, I attended AIB’s Residence Course, which solidified that baking would become my career. I joined Aunt Millie’s Bakeries in 2021 as a lab technician, and now I’m a food scientist.

Which industry contribution are you most proud of?

I’m proud of the formalized, finished product specification program I created. This process not only gave me a greater understanding of Aunt Millie’s entire product line and the plant’s capabilities but also a chance to work closely with QA. I found the most satisfaction in watching our QA managers grow and begin taking ownership. Now when an issue arises, we work together as a team toward the same goal.

What excites you the most about the baking industry?

So much excites me about the baking industry. I love how passionate this industry is, the dedication given to every new challenge and the innovation. I also love using analytical testing to make quality decisions, the ease with which we share information with one another, and the collaboration between suppliers and producers. We never stop growing and striving to do better.

Who in the industry would you invite to a dinner party and why?

The original judges of The Great British Bake Off: Mary Berry and Paul Hollywood. I would just love to talk to them about American baked goods versus British baked goods, proper techniques, and baking pans, and of course, eat some really good desserts.

What year did you join the baking industry, and what led you down this career path?

During high school, I enrolled in the culinary arts program at the vocational center. A few years later, I apprenticed under master baker Warren Roberge, whose passion for the craft and dedication to sharing his knowledge inspired me to pursue a career in baking and pastry.

Which industry contribution are you most proud of?

Giving back to the industry through sharing the knowledge and skills I’ve learned over the past 30 years. I believe we owe it to the next generation to share our knowledge so there is always a future in baking for kids who dream of making this their career.

What excites you the most about the baking industry?

The advancement of technology in the past few years, especially with AI. With that technology, formula development, customer experiences and expectations will become faster, smarter and more successful.

What’s one of the industry’s main challenges right now?

A few things come to mind, but labor tends to be what stands out the most. It has become increasingly difficult to find skilled labor or people willing to learn the art of baking. That’s why I’m very adamant about giving back and sharing my knowledge to future bakers and chefs.

Who in the industry would you invite to a dinner party and why?

Without a doubt Sherry Yard. She’s the reason I fell in love with baking. Her passion and zest for the art inspire me. I would have loved to have been a fly on the wall at Spago. Can you imagine the knowledge you would’ve learned from Sherry and Wolfgang?

With egg prices all over the place, bakers are looking for ways to reduce or replace them without sacrificing quality.

Acti Egg Reduction, Intens Egg Replacement and Sunset Glaze from Puratos make it easy to cut costs while delivering the texture and premium look your customers want. Win-win.

Learn more at puratos.us.

What year did you join the baking industry, and what led you down this career path?

I joined the baking industry in 2009, simply looking for a marketing job. I applied for a creative services role. Once I stepped in, I was hooked. I found myself surrounded by brilliant scientists developing solutions that quietly shape the food we eat every day. My job became about more than marketing. It was about telling stories in a way that connects science to people and showing how innovation in ingredients helps bakers make products that nourish, delight and last.

Which industry contribution are you most proud of?

I’m most proud of my work with the Society of Bakery Women. I help amplify the voices of women in our industry. We’ve created platforms that share their stories, not just as professional highlights, but as real examples of resilience, leadership and community. Highlighting women in baking isn’t just about recognition; it’s about visibility. When people see what’s possible, it changes who sees themselves belonging here.

What excites you the most about the baking industry?

The people. This industry is full of creativity, grit and genuine collaboration. It’s impossible not to be inspired.

What’s one of the industry’s main challenges right now?

Attracting talent. Too often, people don’t realize the wide range of careers this industry offers. We have scientists, engineers, marketers and operators, all shaping the food we rely on. Showing that breadth and purpose is how we keep the next generation curious and connected.

Brownies: Portions: 250 p/min onto a tray. Sheets: 15 - 20 full sheet pans p/min.

Protein/Energy Bars: High-quality protein & energy bars 300 - 900 p/min.

Cookies: Accurate placement, uniform weight, no smearing 200 - 800 p/min.

Gingerbread: Sheeting and shaped cookies 200 - 400 p/min.

Frozen Dough Production: Placed break n’ bake or individuals 600 - 1500 p/min.

Biscotti: Biscotti formed to pan length 1 to 4 rows 10 - 40 p/min.

High production

Small foot print

2 minute die change over

Large inclusion operation

Scones: Artisan scones, all shapes and sizes 150 - 400 p/min.

Full access toolless sanitation

Remote access/monitoring

Intuitive operation and maintenance

Challenging products

What year did you join the baking industry, and what led you down this career path?

I entered the industry in 2010 as an undergrad, completing a two-year, hands-on internship at a frozen dough bakery. What captivated me was balancing the meticulous chemistry of fermentation with a touch of art. Following that, I expanded into tortillas and flatbreads, and now, with C.H. Guenther, I’m excited to delve into our vast portfolio of artisan breads, biscuits, buns and cookies.

Which industry contribution are you most proud of?

I’m most proud of the personal connections and relationships I’ve cultivated. My success has been rooted in the mentors and teams whose collective efforts allow us all to fulfill the mission of feeding consumers globally. My goal now is to inspire the next generation of bakers.

What excites you the most about the baking industry?

The industry has the unique opportunity to deliver consumers both nutrition and joy, as bakery items serve as the centerpiece of so many shared meals and memories. At the same time, we share the weighty responsibility of ensuring we deliver safe, consistent and high-quality items to consumers around the globe.

What’s one of the industry’s main challenges right now?

The biggest challenge is the intersection of innovation and labor. Consumer demand for complex, better-for-you products is here to stay, requiring highly skilled R&D and engineering talent. However, the industry’s severe talent gap in these roles constrains innovation and further necessitates automation, which, paradoxically, only amplifies the need for the specialized expertise we’re striving to recruit.

What year did you join the baking industry, and what led you down this career path?

I got my start in the baking industry in 2012. Growing up, I was heavily involved in 4-H and FFA. Some of my favorite memories are of spending hours in the kitchen with my mom and grandmas baking for the county fair. When I discovered the bakery science program at Kansas State University, I instantly knew it was the perfect fit. The program combined my love for baking, science and agriculture in the most natural way.

What excites you the most about the baking industry?

How much innovation is happening right now. There is this constant push to make baked goods cleaner and more sustainable, while still delivering the flavor and texture people love. It’s forcing us to get creative with ingredients and process, and I love that mix of science, craft and problem solving that keeps the baking industry as a whole evolving.

What’s one of the industry’s main challenges right now?

Maintaining consistency while everything around us changes: ingredients, supply chains and consumer expectations. Clean-label demands and cost pressures mean bakers have to get creative. At the same time, we are seeing a real knowledge gap as experienced bakers retire, so bridging technical know-how with hands-on training is more important than ever.

Which of her industry contributions is Kayla most proud of? WATCH NOW

Who in the industry would you invite to a dinner party and why?

I would invite Margaret Rudkin and Cordia Harrington for their incredible contributions to the baking industry. They’re both true trailblazers whose stories and insights I’d love to hear firsthand. I’d also like to include my mom; she sparked my love of baking and has always been my biggest supporter. It would be a good mix of inspiration, wisdom and reflection over good food.

What year did you join the baking industry, and what led you down this career path?

I joined the baking industry in 2019 when I started at Killer Brownie as the packaging manager. A year later, I became the plant manager, overseeing both baking and packaging, and later the director of Support Operations. I wanted to apply my leadership skills in a fast-paced, hands-on environment where I could make a real impact.

Which industry contribution are you most proud of?

Helping transform our operations at Killer Brownie. I’ve led improvements across logistics, production, safety and supply chain. I’m especially proud of building strong teams and mentoring leaders who now drive our success every day.

What excites you the most about the baking industry?

Its unique blend of tradition and innovation. I love that we’re part of an industry that brings joy to people through something as simple and powerful as a brownie, yet behind the scenes, it’s constantly evolving. Whether it’s improving food safety, streamlining maintenance or enhancing quality, every day presents a new challenge.

What’s one of the industry’s main challenges right now?

Workforce readiness, especially as automation and AI become more common. On top of that, rising costs for ingredients and services are forcing bakeries to rethink sourcing and pricing.

Who in the industry would you invite to a dinner party and why?

The founder of Milk Bar, Christina Tosi. She brings a fun vibe to baking and champions making desserts feel personal. Christina proves that success comes from the courage to break rules, a passion for creativity and a commitment to joy.

Unmatched product quality, scaling accuracy, and versatility

n Gently handles dough

n Unmatched scaling accuracy

n Precisely scales a wide range of dough portions

n Produces a variety of crumb structures

n Handles absorption rates from 45% to 95%

n No divider oil needed

n Fast, easy changeovers

n Come run your product with us at the Reiser Customer Center.

What year did you join the baking industry, and what led you down this career path?

I joined the industry in 2023. I’ve always had a passion for manufacturing and spent the first part of my career in the dairy manufacturing industry. A recruiter called me in January 2023 and told me about a position with a bakery in the Ohio/ Kentucky area. I thought it was a great opportunity to stay with my passion while expanding my knowledge base.

Which industry contribution are you most proud of?

Water, food and shelter are some of the basic requirements all humans need to survive. There are very few things that empower or fulfill someone more than knowing you are helping to feed the world. Bread is one of the most consumed products, and at Klosterman, baking it safely and making it better is a part of the culture we live in.

What’s one of the industry’s main challenges right now?

The ever-changing FDA regulations around clean labeling and ongoing tariffs are challenges we proactively plan for and work through.

Who in the industry would you invite to a dinner party and why?

I’d love to sit back down with Kevin Stevens (New Horizons Baking Co.) and pick his brain even further. Passionate leaders are contagious, and his background and years of experience are hard to come by. To be a subject matter expert is a wonderful skill, but the ability to engage and instill that passion in others is a true talent.

Scan here to learn more about our full range of bakery packaging.

What year did you join the baking industry, and what led you down this career path?

I joined the baking industry in May 2024 after several years working in high-complexity food systems outside the commercial baking industry. I was intrigued by the opportunity to translate my background in process optimization, customer support and evidence-based problem-solving in an industry rooted in both tradition and innovation. The chance to learn from seasoned bakers while contributing a fresh, systems-driven perspective is ultimately what intrigued me.

Which industry contribution are you most proud of?

I’m most proud of my work with Middleby’s RapidBake Oven, which applies microwave energy to reduce bake time and explore new processing possibilities. Helping shape a technology with the potential to redefine efficiency and product variety has been one of the most exciting aspects of my role.

What excites you the most about the baking industry?

The intersection of art and science within the baking industry. It’s a field where creativity, craftmanship, and intuition meet chemistry, engineering and precision. That balance, where small technical changes can transform both process and product, is endlessly fascinating and fuels my passion for innovation.

What’s one of the industry’s main challenges right now?

The widening gap between experienced bakers and the next generation. As seasoned experts retire, knowledge transfer and hands-on training must be strengthened to preserve tradition and support future innovation.

What does Carter see as one of the industry’s biggest challenges?

WATCH NOW

What year did you join the baking industry, and what led you down this career path?

I joined in 2014. My first job working in a pizza kitchen in high school got me interested in pursuing a career in baking. I was also influenced by my father and sister, who studied milling and baking at Kansas State University. I saw how much they enjoyed working in the industry.

Which industry contribution are you most proud of?

Giving opportunities to others through my association work with the American Society of Baking (ASB) and Cereal & Grains, specifically creating the ASB Rising Baker award. Seeing young professionals gain recognition and confidence through this platform has been incredibly rewarding. It’s fulfilling to know the program helps strengthen the next generation of leaders in our industry.

What excites you the most about the baking industry?

The innovation space, particularly developing new wheat varieties with improved functionality that enable cleaner-label products and make wheat more exciting. There’s still so much untapped potential for innovation. There are incredible opportunities to collaborate with farmers, universities and research institutions to explore betterfor-you and functional benefits that can meet evolving customer needs and inspire the next generation of products.

Who in the industry would you invite to a dinner party and why?

My first professional mentor, Mark Baczynski. He is full of wisdom. Unfortunately, I rarely get to see him as he is in Australia. Second would be the late Jose Lopez. The whole industry misses him, and it’d be great to see him one more time.

Which of her industry contributions is Rachel most proud of?

WATCH NOW

What year did you join the baking industry, and what led you down this career path?

My grandfather, Tilmon Brown, has owned New Horizons Baking Co. since I was three weeks old, and some of my earliest memories are of walking through the plant with him and my parents, watching the buns come down the line. After finishing graduate school in 2019, my family welcomed me into the business and gave me a chance to learn the industry from the inside. Today, I’m proud to continue what my grandfather started while finding my own way.

What excites you the most about the baking industry?

The baking industry offers such a wide range of opportunities. Everyone is welcome here. There’s a place for every person, no matter what they studied, where they came from or what they’re passionate about.

What’s one of the industry’s main challenges right now?

Our world isn’t glamorous or the flashiest, but it’s one of the most important. People often focus on what they can see and rarely pause to think about what’s happening inside. What happens behind our doors is incredibly special, and it deserves to be seen and appreciated.

Who in the industry would you invite to a dinner party and why?

Joanie Spencer (Commercial Baking ’s editorin-chief), because her knowledge, strength and charisma pull you in and keep you laughing and learning, and my mom, Trina Bediako, the CEO of New Horizons, because not only is she my best friend, but she is also my baking industry idol. She’s proof that we can be whoever we want to be. She’s also proof that the sky is the limit in this industry.

HEALTH-FORWARD BAKED GOODS START AT THE PURATOS INDUSTRIAL PILOT BAKERY — POWERED BY AMF

Whenhealth-forwardideasmeetexpertformulationandscalable technology, innovation moves faster. At the Puratos Industrial Pilot Bakery, powered by AMF, you can turn health-forward ideas into scalable products — powered by real consumer insights, expert collaboration, and the latest AMF baking technology. From better-for-you formulations to functional ingredients, you can take your next big idea to market in a single day.

PRIORITIZE PRODUCTS THAT SUPPORT DIGESTION

What year did you join the baking industry, and what led you down this career path?

I started at Reading Bakery Systems in 2017 after finishing my mechanical engineering degree. It was a new industry for me, and I haven’t looked back.

Which industry contribution are you most proud of?

I’m most proud of the work I’ve done to improve the design and performance of industrial ovens. I’ve contributed to both early-stage concepts and production-ready systems. These projects pushed me to rethink traditional design approaches and find new ways to improve energy efficiency and baking consistency. Seeing those ideas come to life and actually make a measurable difference in performance is incredibly rewarding.

What excites you the most about the baking industry?

The challenge of making an energy-heavy process more efficient and sustainable. I work in oven design, so I see firsthand how much opportunity there is to improve energy use while also tightening up process control and stability. When all the pieces come together, you can make a big impact on sustainability and product consistency.

What’s one of the industry’s main challenges right now?

In oven design, it’s finding ways to meet sustainability goals without driving up the cost of food. Thermal systems are a major energy consumer, and while there are promising technologies, they often come with higher upfront costs or integration complexity. The challenge is figuring out how to implement these improvements in a way that maintains product quality and throughput, while also keeping operations cost-effective.

What year did you join the baking industry, and what led you down this career path?

I started full time right out of college in 2023. I have always had a passion for food, so a career in the industry was the natural next step for me. To me, baking and the food industry as a whole is one of the fields where human ingenuity and creativity get to thrive.

Which industry contribution are you most proud of?

Most of my time at Sugar Foods has been spent on the packaging side of the business. In that time, we have been diligently testing and converting our standard film structures to more sustainable options through new developments in recyclable and compostable materials.

What excites you the most about the baking industry?

Baking brings people together. From new innovations to perfecting old classics, the industry is propped up by the uniquely passionate people working in it. It excites me to see all the love and hard work that goes into making the products that feed people across the globe.

What’s one of the industry’s main challenges right now?

Like other industries, the push to meet sustainability goals will be a considerable hurdle. While it is a complex issue, I have no doubt that the industry will tackle it and come out better for it.

Who in the industry would you invite to a dinner party and why?

I would like to have dinner with Ivy Ku and the team from Fondry in LA. Simply put, I have so much respect for the artistry they showcase with their pastries; I would love to hear the research and stories about how they got to where they are now.

What year did you join the baking industry, and what led you down this career path?

I joined in 2014. I’m third generation and grew up around the business. Our apple crumb was a must-have the night before a big basketball game. Yet, it wasn’t until my grandfather and Wick’s founder, Duane Wickersham, passed that I started having conversations with my father about joining the company. My grandfather built a lasting legacy, and we plan to continue it.

Which industry contribution are you most proud of?

Developing our direct-to-consumer division during the pandemic was incredible. It revealed that the consumer really does value a high-quality pie. Seeing our pies sold for fundraising every year is even more rewarding.

What’s one of the industry’s main challenges right now?

For us, it’s finding great people, although that’s not a new problem. It takes great people to make great bakery products.

Who in the industry would you invite to a dinner party and why?

(Mark) Par Grandinetti of Rocky Mountain Pies. Par has a wealth of knowledge and has lived his life to the fullest, from Olympic skiing to filling impossible POs. He is an inspiration for any aspiring pie maker. Our industry is lucky to have such a leader.

At Chabaso Bakery, the Negaro family’s commitment to the greater good lives on through the business … and beyond.

BY ANNIE HOLLON

Commercial Baking is proud to present the 2025 Social Impactor of the Year. This annual recognition highlights one company’s dedication to philanthropy, education and social change with the goal of making a positive impact on its workforce and the communities it serves.

Being a force for good as a company starts at the top, with those leading the charge setting the standard for the entire team. Today, New Haven, CT-based Chabaso Bakery, a Certified B Corporation, maintains these efforts, supporting its team members, community, region, and budding food and beverage businesses while also supplying grocers and retailers throughout the East Coast and Midwest with an array of par-baked frozen artisan breads.

Through the many iterations of the business — from its early days as Atticus Bookstore on Yale University’s campus in 1975 and the addition of the cafe with fresh bread in 1981 to the spinoff-turnedcommercial bakery established in 1995 — prioritizing people was always the throughline. Even the name comes back to the people, a nod to CEO Charles “Charlie” Negaro Jr. and his sisters, Abigail and Sophia.

When Negaro Jr. succeeded his father — and Chabaso’s founder — Charles Negaro Sr. as CEO in 2019, the torch was passed and with it, the responsibility of keeping the business’ ethos alight. The foundation of this company philosophy can be traced back to Negaro Sr., who ignited the spark years ago after meeting with a former employee whose undiagnosed diabetes caused him to lose part of his leg.

“My dad really took that to heart, like he could have prevented it somehow,” Negaro Jr. said. “That’s the spirit my dad always started things with.”

After hearing the employee’s story, Negaro Sr. was inspired to create and implement a company-assisted healthcare plan in the early ’90s and establish a 401K program with a high match in the early aughts.

“Almost to a fault,” Negaro Jr. said, “my dad put the people that work here first.”

Today’s leadership team achieves this by paying tribute to the past, supporting its team members and community, and investing in the future for food and beverage. For Chabaso employees, this

includes creating strategic partnerships with local organizations providing valuable services.

“In New Haven and in our area, there are a lot of organizations trying to help employees at other companies or provide [key] services,” said Reed Immer, director of sales and marketing for Chabaso. “For us, the challenge is connecting the dots and making sure we’re embarking on smart partnerships and not trying to reinvent the wheel if there’s an organization around the block that could help, too.”

Chabaso also does what it can to offer a great place of employment.

“The biggest thing that connects all of it is making sure you’re looking out for everybody,” Negaro Jr. said. “Making bread is easy; having 200 people feel good about the work they’re doing is the hard part.”

This includes ensuring vital information is available to employees in a variety of languages, including French, Spanish and Pashto, as well as opening the door for people from all walks of life. All these factors create an inviting,

accessible place to work for the people of New Haven.

“We’ve altered our hiring practices so that we’re a little bit more lenient in what we look for in background checks,” Negaro Jr. said. “Anybody deserves a second, third or fourth chance to earn a living.”

Philanthropically, the baking company has a long history of giving back to the community. This includes it’s Random Acts of Bread program, which celebrates organizations doing the work to uplift the lives of local residents.

“Although ongoing donations have been a long part of Chabaso’s initiatives, we saw an opportunity to align some of those donations with the seasonal and holiday brand campaigns we’ve been running,” Immer said. “Our thinking was that since we’re already assembling collections of fun recipes and signage for holiday and special occasions throughout the year, why not leverage those to put some extra smiles on the faces of our neighborhood heroes?”

The company boasts a long history of donating bread in the community. In 2024, Chabaso donated nearly 300,000 loaves and rolls to regional non-profits and hunger relief organizations, and it’s on track to surpass that figure this year. The bakery’s contributions also extend beyond its facility and the immediate New Haven community to other businesses, particularly up-and-comers in the Connecticut food scene.

Scaling a business is no small task, and the leaders at Chabaso know this well. Relying on business acumen gleaned from the two Atticus New Haven retail locations and Chabaso, the team saw an opportunity to lend its insights to emerging brands as well as create connection opportunities. As a result, Negaro Jr. and Immer co-founded the CT Food Launchpad, an accelerator designed to support early-stage food and beverage businesses based in the Constitution State.

“We saw there were a lot of resources for people who were going from zero to one, but there weren’t a lot of people who were helping folks get market-ready products onto shelves,” Negaro Jr. said.

While the project started lowkey with the two hosting business-to-business outings connecting local entrepreneurs, the formalization into CT Food Launch -

pad extended the concept beyond guidance. In addition to giving away more than $100,000 to Connecticut-based emerging brands, Chabaso, in partnership with the School of Management at Yale University, hosts The Big Connecticut Food Event, an annual conference that unites local companies with wholesale decision makers from various retailers. Creating an intimate environment for organic connections establishes a space for productive conversations.

“There’s a lot more we can be doing, but starting with the annual event has been really exciting,” Immer said, sharing that the company is working toward deepening the launchpad’s partnership with Yale and other regional universities and potentially expanding to other regions.

Chabaso’s impact is vast, much of which can be affirmed within the framework of B Corp certification, a rigorous process identifying companies with responsible business practices. With key impact areas including workers, community and customers, doing the work to earn the recognition was a no-brainer given Chabaso’s support of its team members, community and consumers.

“I was introduced to B Corp around 2010, and that became something I zeroed in on to help us hold onto that culture [my dad] started,” Negaro Jr. said, noting that the guidelines of the certification helped the company better identify and concentrate efforts on making the biggest impact possible.

The certification offers a tangible emblem to identify all the good work Chabaso does, along with serving as a reminder to keep these practices at the core of the bakery operations.

“We think of the B Corp framework as a compass,” Immer said. “It plays a large role as we try to update and optimize our supply chain and consider which ingredient or packaging producers to partner with. Similar to our passion for helping regional food businesses, we want to make sure that we’re making smart choices.”

From the first flicker of people- and community-centered business under Negaro Sr.’s foundation to the fullyfueled hearth under Negaro Jr.’s leadership, Chabaso Bakery is making lasting change and stoking that original flame three decades later. CB

EXPERIENCE THE RENOWNED QUALITY OF BAKED GOODS PRODUCED ON A RADEMAKER LINE

The Rademaker Experience Center (REC) is conveniently located near Chicago O’Hare International Airport, the center is equipped with several state-of-the-art Radini production lines. The facility also includes mixers, ovens, proofers, and freezers to support comprehensive product testing. Our experienced dough technologists are available to assist with demonstrations and trials.

EXPERIENCES

•Equipment Demonstrations

•R&D Testing

•Operator Training

FACILITY FEATURES

•Consumer Experience Kitchen

•Private Meeting Space

•Shipping / Receiving Docks

RADEMAKER SERVICES

•Dough Technologist Support

•Ingredients Procurement

•Formula Consulting

•Product Sample Shipping

•Operations Consulting

•Custom Component Testing

COMMITTED PARTNER

Servant leaders for ABA, ASB and BEMA take stock of the ups, downs and big opportunities.

The commercial baking industry certainly had its share of challenges over the past year. But it also demonstrated resilience and collaboration as bakers and suppliers came together across the board to discover new opportunities and solutions. Add in two international tradeshows — with IBIE at the peak — and there has been no shortage of fodder for reflection.

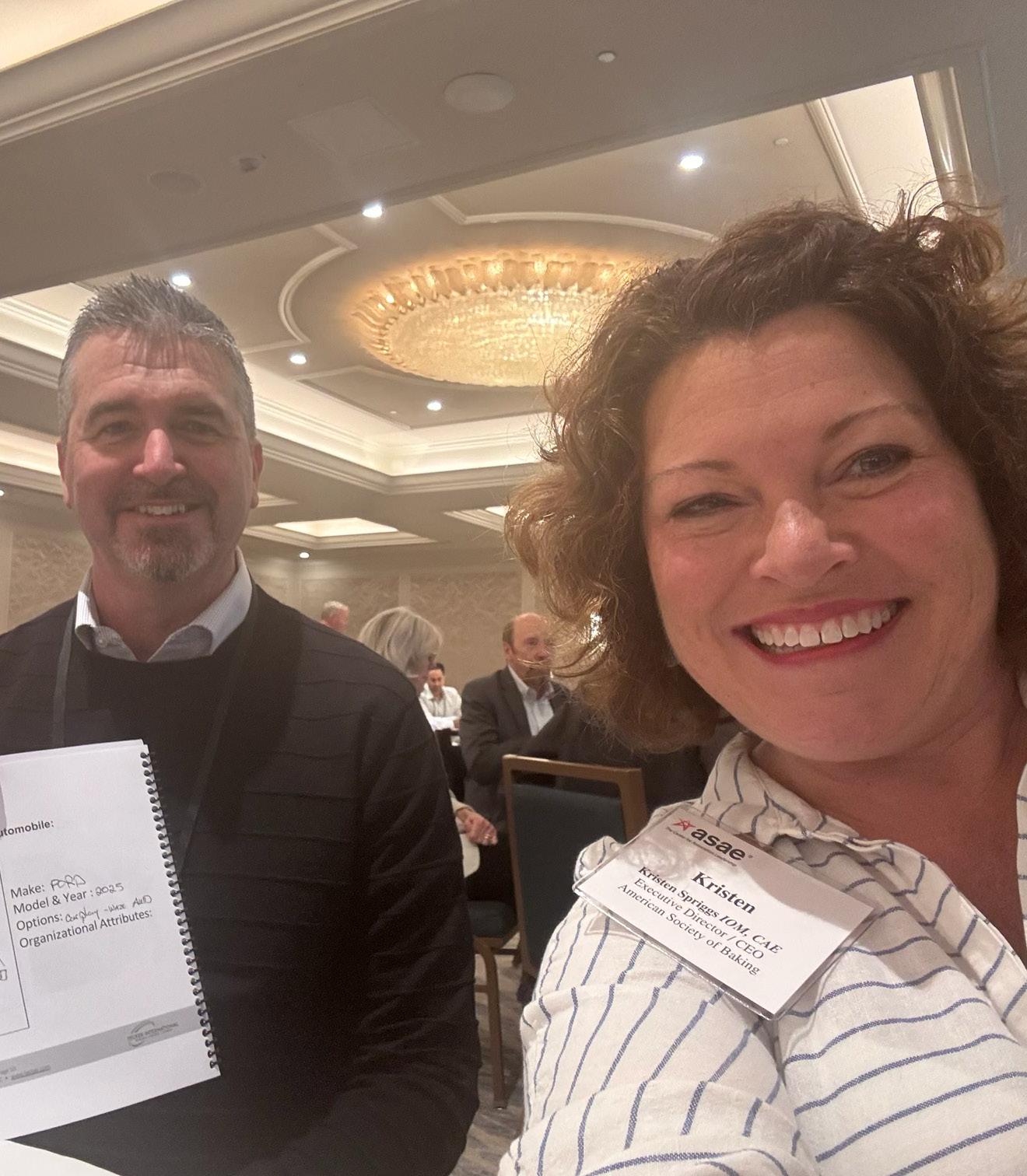

In the first roundtable of association servant leadership, Bill Quigg, president of Richmond Baking and More Than A Bakery; Matt Bowers, senior director of R&D for New Horizons Baking Co.; and Jay Hardy, VP of sales at J&K Ingredients — board chairs for the American Bakers Association (ABA), American Society of Baking (ASB) and BEMA, respectively — sat down with Joanie Spencer, editor-inchief of Commercial Baking . They each shared their perspectives on what stood out in 2025 ... and what they’re looking forward to in the year ahead.

Let’s start with some of your biggest moments from the past year.

Matt Bowers: Over the past year, ASB has truly doubled down on education and connection. We launched the Commercial Bread Production course, which is a hybrid program blending 10 virtual courses and a four-day hands-on workshop. We celebrated our first round of graduates, each leaving with practical expertise they can take back to their bakeries. We’re also expanding learning opportunities through preconference workshops at BakingTECH 2026, including Sensory Analysis 101 and the Evolution of Food Safety. This year, we strengthened our sense of community at IBIE by hosting the Recharge Lounge, where bakers, suppliers and students connected and shared ideas all together. It’s been a year focused on empowering professionals through learning and collaboration, and I couldn’t be more proud of the team.

Jay Hardy: For BEMA, coming off a very successful convention in Puerto Rico, we headed into IBIE, which was definitely the highlight this year. While most of our member companies exhibited, BEMA also played a large role with IBIEducate, sponsorships, and, of course, the volunteer programs and Wholesale Baker Stage. As a co-owner of the show, we’ve taken on more responsibility over the past few cycles, especially growing IBIEducate to offer more than 250 learning opportunities. And of course, working alongside all the associations, including ASB and ABA, we’ve all truly made IBIE the industry standard.

Bill Quigg: Reflecting on ABA’s year, advocacy has been at the heart of everything we do amid the landscape facing bakers and allieds. ABA has proudly championed the baking industry by representing our interests in Washington and state capitals, keep -

ing members informed on issues that affect our businesses and elevating our industry’s essential role in feeding the country. ABA’s advocacy work requires strong relationships with our legislators and having open dialogue to help them understand the facts and science behind some of the thoughts that may be stirring in consumers’ minds. That was highlighted by the Fly-In in DC, when we met with folks from the House and Senate to understand their position and help them understand ours. Having a strong team representing our membership in DC has been really beneficial.

But the pinnacle of the year has to be IBIE and bringing the industry together in such a huge way. We had great participation from allied members and all the bakeries that were represented. It was such a compliment to the strength of the show and the strength of the partnerships that we have. That’s a shining star moment for me.

How would you summarize all the ups and downs of 2025?

Bowers: It’s been a roller coaster of a year in our industry. Despite economic ups and downs and regulatory uncertainties, one thing that stood out was the resilience and eagerness of the baking community to come together. Folks are hungry for networking and knowledge, and having two big gatherings in the same year helped rally people. It gave everyone a chance to share strategies, navigate cost pressure, compare notes for new regulations and see the latest innovations around the world. 2025 tested us with rapid changes, but it also validated the importance of staying connected when things are uncertain, whether politically or economically. The industry pulled together, and that gives me a lot of optimism going forward.

Quigg: This year was challenging, of course, but I say that not only from an ABA perspective but also from a broader industry perspective. A lot of the interests between bakers and allieds are very closely aligned. When you have situations like tariffs that, regardless of the economic impact, cause uncertainty, it’s difficult to effectively manage your business. And frankly, it filters down to everyone’s customer base as well. That said, we have seen a positive shift in predictability in the past few months, which seems to be something we can manage better than what we dealt with in the first half of the year.

Hardy: It all really shows how adaptive our industry is. We adapted, we tweaked, we transformed our offerings to meet the needs of our customers. And that will continue. Remember when Atkins felt like the end of the baking industry? But we all adapted. And to share our knowledge, whether it’s at iba or IBIE, I could see the level of industry participation around the world. It shows you that people are eager

to learn and stay relevant. And that gives us all the opportunity to understand how we can be better.

What’s the biggest change you’ve seen in the past five to 10 years, and how have your associations adapted?

Quigg: Specific to ABA, the political environment has certainly evolved, along with having a strong advocacy team focused on that as a core value proposition. As a long-time member of ABA, I’ve gained tremendous value having that voice in Washington that I can count on to advocate for what’s in the best interest of our industry.

More recently, I’ve seen a positive shift in collaboration among associations. There’s a real desire to be efficient with our membership, money and resources, and associations have been focused on the strengths of each organization while also helping one another dial into their strengths.

We have this great dynamic, this great energy as an industry, and when we play into our individual strengths, the industry becomes stronger. Today, it’s less of a competitive landscape and much more of a collaborative one.

Bowers: One of the biggest shifts has been the decline of traditional training programs. I had a chance to attend AIB, but that’s no longer available, and it’s left a big gap in industry learning. ASB recognized that gap early and made it a priority to bring practical education back to the industry through hands-on training. The hybrid bread course allows professionals to learn without stepping away from their jobs for weeks. We’re also expanding modular online content and short-format workshops to keep skills current. As technology advances, ASB is, in turn, becoming a go-to resource for technical education, so the next generation of bakers can build on the science and the craft, even as the industry evolves.

Hardy: The most significant change is the actual rate of change, in areas like the economy and the workforce. Matt, you said it perfectly: technology, consumer needs and wants. The change is happening at a pace that I don’t believe has ever happened. For BEMA, our mission and vision focus on finding ways to adapt commerce. We have conversations and strategy sessions about honoring decades of tradition and also being bold enough to make change with new ideas. Today’s world is a place for change, and BEMA is strategically planning for it.

How are you addressing the challenges your memberships face these days?

Quigg: There are some interesting consumer shifts, particularly as they relate to GLP-1 drugs, as well as ultraprocessed foods, specifically understanding the difference between accurate, scientific information and what’s just a headline.

If you think about the nutrition-packed nature of the products we make — the whole grains, the fiber contents, the vitamins — having ABA educating consumers and legislators on what science tells us about our food is really beneficial. ABA is coming out with position statements regarding things such as artificial flavors and colors, and that’s helping people understand where we are as an industry and where we’re going.

With immigration, we’re challenged with building consensus on a path forward. We need one that makes sense for the country as well as our industry, while appreciating and respecting different viewpoints. We have to balance that with the fact that we need a strong, viable workforce, which means figuring out the best way to advocate on behalf of our industry. That’s a challenge that’s keeping me up at night, from the standpoint of trying to gain consensus in the industry. We’re not there yet, but we’re working on it.

Bowers: For ASB members, one major issue that keeps them up at night is the workforce, finding and developing skilled people. There’s a talent gap, and our members are feeling the pinch. We hear concerns like, ‘How do you train the next generation fast enough? How do we retain new hires to become longterm assets?’ We’re laser-focused on workforce development to ease these worries. We’re providing more education and training resources, from the new bread production course to an expanded lineup of technical webinars throughout the year, and it’s all aimed at upskilling employees in critical areas. And just as important, we’ve ramped up our mentorship program, pairing emerging professionals with seasoned veterans one-onone so knowledge can get passed down. These matches create relationships that build confidence, loyalty and support.

Hardy: I’ll just continue there. When we think about BEMA, we have our equipment members and allied members. Giving the allied perspective, I can say labor is still an issue for manufacturing facilities. One of the big takeaways from IBIE was capital. Where is the capital? Is it automation, increased quality? More AI and understanding those needs? This all comes from an equipment standpoint and a training standpoint. At BEMA, we’re tapping into discussions through the Baking Industry Forum about how to use tools like AI. And from an ingredient standpoint, it’s trying to understand and listen to the consumer, following consumer trends, listening to what’s being asked for. By working with our baker partners and giving them what they need to fulfill that automated side of their business, we’re helping make sure consumers receive the products they want, and that they’re high quality and affordable. It’s about making sure we’re able to keep feeding people.

Challenges often lead to opportunities. What opportunities do you see for the year ahead?

Bowers: The greatest opportunity for us is in collaboration and adaptability. The pace of change, from automation to evolving food safety regulations, demands that we work together across organizations and sectors. Our workforce gap study with ABA and the International Dairy Deli Bakery Association gave us actionable insights into where skills are lacking, and we’re using that data to shape our new training and development offerings. As we move forward, shared resources and joint advocacy will be key because the more we align efforts across the industry, the more future-ready we’ll all be.

Hardy: It goes to workforce dynamics. It’s skill shortages, to Matt’s point, with training, human capital, ongoing strategic risk, but it’s also an opportunity for those who lead the workforce strategies. We need to have trained bakers, and we need to have trained engineers, from operational engineers to the ones who know how to fix the equipment.

With the policy and regulatory pressures impacting manufacturing, how do we continue the food safety aspect without creating a higher price tag? And how do we get there with more functional ingredients? Having these challenges definitely creates opportunities. It’s all in how we embrace it and not run scared from it.

Quigg: I see real opportunities for ABA to help elevate the value of our products and drive renewed policymaker understanding. While we faced challenges this year, I’m optimistic. Conversations with legislators and government agencies have been productive, and our relationships with FDA, USDA and others are strength -

ening in meaningful ways. Dialogues are becoming increasingly valuable, positioning ABA to make greater progress for the baking industry.

I’m also hopeful that the tariff conversations are mostly behind us. That’s going to allow better predictability for bakeries on the capital spend side, which gives me optimism as well. Having these open conversations and coming to mutual understandings will certainly serve our industry well.

your

from the attendee, exhibitor and association perspectives?

Hardy: This is the first year that J&K has exhibited at the show, and our marketing team put together a fantastic booth in the North Hall. I’ve got to say, the North Hall was buzzing. It was a blend of wholesale and retail vendors, just buzzing with people every day. And the upgrades to North Hall made a big difference. Being a first-time exhibitor and having some first-time attendees working in our booth, it was amazing to see those eyes wide open. It did not disappoint.

From the perspective of BEMA as a co-owner of IBIE, we had the most booths ever, at just over 1,000. There were some ‘mega’ booths with multiple brands, and we also had strong numbers for first-time exhibitors. In talking to some of exhibitors who are also BEMA members, this cycle seemed to host many attendees who were decision makers. As much as companies see IBIE as a reward for a job well done, I think this year it was, ‘Let’s go get some business done.’ I believe the quality of leads may have exceeded previous show cycles.

Quigg: I was just wide-eyed in amazement at how successful IBIE was! Just

walking around the show and spending time with friends, but also meeting new equipment, ingredient, packaging vendors and all kinds of different people was so fulfilling. From an ABA perspective, I had this immense pride and thankfulness for everyone’s hard work, and from a baker member standpoint, I learned so much. The breadth of what I learned was amazing. Listening to professionals talk about values and making real contributions in the community, as well as specific ways to make manufacturing more efficient, more effective, it was all invaluable. There were just so many different aspects of the industry represented, and once I immersed myself in learning about the various facets, it really broadened my perspective.

Bowers: I heard tremendous feedback from our members, volunteers and partners about what an energizing event it was. IBIE was a powerful reflection on how vibrant and connected our industry is right now. And for ASB, this year’s participation through our Recharge Lounge was especially exciting. It was a space where people could take a break, recharge — literally and professionally — and have meaningful conversations about what’s happening across the industry. We also hosted fireside chats, which were informal sessions with industry experts on topics like workforce, recruitment, food safety, consumer trends and future innovations.

From a broader perspective, I was encouraged to hear how strong the collaborative energy was throughout IBIE. There was clear alignment between ABA, BEMA and RBA, all working toward common goals. It was so satisfying to see ASB contribute to that ecosystem by serving as a hub for learning, connection and professional growth within the industry.

Consolidation was visible at IBIE. How does that impact your organizations?

Hardy: I think BEMA really took the opportunity to see what consolidation looked like at IBIE and consider what it means for membership. That’s something that will play a role as we work on our five-year strategic plan.

Quigg: I would also note that the breadth of the industries we’re representing is getting wider. These supplier and vendor companies have different lines of business that, by default, create different product opportunities. Historically, ABA has been a ‘bread and bun’ kind of organization. Many years ago, that was sort of the dominating category, right? And while, certainly, it’s hugely important to ABA, it’s also gotten so much broader. I mean, to have a ‘cookie cracker guy’ as chair of ABA is a shift.

Bowers: That all mirrors what we’ve been seeing as well. From ASB’s perspective, consolidation has meant that some of our member companies have grown larger and more complex, while at the same time, many smaller, specialized suppliers have found new opportunities to innovate and serve those larger systems. The membership mix is evolving, but the sense of community and shared purpose remains strong. In fact, we’re seeing more collaboration than competition among our members, as they realize each plays a crucial role in sustaining a healthy supply chain to serve the full spectrum of the industry. That’s why it’s so important for us to adapt by expanding our offerings and to make sure that, regardless of company size, every member finds value.

Consolidation will likely continue, but we see an opportunity in that larger organizations tend to have greater resources for R&D and workforce development, and that creates a ripple effect of knowledge and innovation that benefits the entire industry. Our job at ASB is to keep the channels open to make sure those insights, technologies and training opportunities reach everyone. And if we can keep that collaborative spirit strong, consolidation won’t shrink the industry’s influence; it’ll strengthen its capacity to innovate and evolve together.

Looking to

what words of wisdom can you offer your association members?

Quigg: We’re going to advocate for you, for your positions, and I can tell you with 100 percent certainty we care about our members. ABA is truly listening to what our companies have to say and understanding that differing viewpoints are welcomed. We’ve got your back. It’s as simple as that.

Hardy: I always like to say that people need to gather. Not only do decision makers in our industry want to see and interact with other industry leaders and associations, but you also just never know where the next idea, connection or ally will come from. This year has been a bumpy ride. The market and industry conditions could remain a little volatile, but staying connected in all our associations will help us all be successful as we get through it. BEMA’s mission is to connect, educate and provide resources, and we’ll keep doing that while adapting to change.

Bowers: The baking industry thrives when we share knowledge and work together, even in times of change. Our community’s strength comes from connection and collaboration. Stay engaged, stay curious, stay connected, whether through mentorship, professional development or participation in events. Every contribution makes the industry stronger, and ASB will evolve alongside you, with opportunities that meet the moment. We can’t just talk progress; we have to make it happen. Together, we can shape an industry that’s innovative, inclusive and ready for the future. CB

Precision is the key to consistent quality. With Pfening, quality is automatic.

Pfening's dry and liquid ingredient systems deliver repeatable, accurate weights based on your recipe formulation.

Pfening's Enviroblender (EBM 7) provides automatic, precise control of water batch weight and temperature.

Pfening proofing systems create the perfect temperature and humidity environment for raising your yeast-based dough product.

Pfening solutions help our customers embrace automation, improve consistency, and meet ever-changing market demands.

With the right approach to AI, companies can integrate — and improve — their operations.

BY ANNIE HOLLON

New technology can often be daunting or intimidating, creating more questions than answers, especially when an innovation is in its infancy. But it can also prove promising when given the chance to showcase its capabilities.

These sentiments and more ring true regarding AI, a technological disruptor that, for bakers and equipment manufacturers alike, can do much more than they imagine. The potential behind it is what keeps the Baking Industry Forum (BIF) intent on not only experimenting with AI but also sharing the possibilities on and off the bakery floor.

“We see the vision of the future,” said Mike Porter, president and COO of Norwalk, OH-based New Horizons Baking Co. “AI won’t replace people, but people who understand how to use AI will. Everybody’s trying to do more with less, so we recognize that this is an opportunity to utilize technology to help advance our business and limited resources to achieve what we can’t do today. Why not leverage the technology that’s out there and available for us?”

The BIF cohort — composed of bakers and suppliers — meets throughout the year to host crucial discussions on hot-button issues impacting the baking industry. Previous topics have included preparing for FSMA and the capabilities of RealWear technology.

Points of entry for AI vary from business to business. At Portland, OR-based Franz Family Bakery, a century-old family-owned baking company, the team is beginning to test what AI can bring to the business in terms of consolidating training information.

“For us, we’re taking a lot of our in-house baker trainings that we’ve built throughout the years and uploading that into an agent,” said Justus Larson, VP of operations for Franz. “Then when things come up, we’re using that agent to do a double check.”

While still in the early stages, Larson and the team are experimenting to determine what information the system offers when a user poses a question and whether the response is accurate. Taking the time to test the te chnology and clean up or tweak potential responses enables the team to train the AI agent to align with its prospective operational needs.

AI’s vast applications are particularly intriguing in terms of sharing industry know-how. In a time when companies are struggling to find skilled staffing, technology that can pass knowledge to other employees and fortify resources could be a game changer. At Franz, AI won’t replace current training; rather, it will serve a supporting role.

“We’re trying to make sure it’s not the only thing we’re relying on,” Larson said. “We still need people who understand the baking process; it just hopefully shortcuts the education for new people coming in.”

At New Horizons, AI is supporting the human resources department and improving internal communications. The company began using AI to consolidate employee feedback from pulse and engagement surveys.

“To me, the comments of those surveys are some of the most important information,” Porter said. “But when you try to analyze 500 of those, how do you gather the themes?”

“We still need people who understand the baking process; [AI] just hopefully shortcuts the education for new people coming in.”

Justus Larson | VP of operations | Franz Family Bakery

The New Horizons team entered a batch of responses into the AI agent and, in under a minute, received a complete, accurate summary of an engagement survey. With this, Porter had the necessary information to discuss results and respond to team members’ feedback quickly.

Spurred by that success, New Horizons is exploring what other branches of the business can be taken to the next level with this technology. Prospects range from combing through job applications to translating training materials into different languages, helping to establish a more standardized and accessible operational structure.

While some BIF members are still in the early stages with AI, others are already fully engaging with it. Richard Ybarra, senior engineering manager for Lakeland, FL-based Publix Super Markets, shared that the company is currently using the technology in its various manufacturing facilities, including bakery operations.

Publix’s digital information is created and housed in “silos,” which store operational, maintenance and sanitation information specific to one piece of equipment. By having these collections of data segmented out, team members can use AI to sift through a smaller data set for a single machine vs. the whole manufacturing line, reducing turnaround time.

“Segmented data makes it much easier to move through, easier to pull out and easier to put back, and that’s what you want to do,” Ybarra said. “You want to limit where you’re doing your searching … You don’t want [AI] bouncing all over the place, and it will if you just have one big pot of information.”

Here's how to layer small optimization wins into major long-term gains. ij One AZO partner used this process to double their output over 20 years without new lines.

Building out the agents and data structure varies from operation to operation, but taking the time to do so in a way that makes sense for each particular company makes it easier in the long run.

“I can’t emphasize enough, this thing will grow as you utilize it for various parts of the operation,” Ybarra said. “It’s just going to learn.”

In addition to bakeries, AI is influencing how manufacturers design and build equipment. Brandon Brilliant, president of AMF Americas, outlined the potential behind integrating the technology directly into machinery.

“We talk about how to create training models, segment data and impart legacy knowledge of all the retiring folks onto new teams,” he said. “What if we can take that data and legacy knowledge and impart it onto that machine itself without needing to do operator personnel training?”

AI can be used in several areas of baking operations, including preventive maintenance, determining the perfect mix time, and instant temperature adjustments in the oven. Making these changes begins with data collection. Bakers can add the tools needed to their existing equipment to harness critical insights and connect with their IT teams to ensure data is processed in a way that best aligns with each business’ needs.

“We believe the biggest impact areas are going to be on mixing, oven and packaging systems,” Brilliant said, “so we want to start making real-world applications and differences in those areas.”

To set a strong foundation for widespread use of this technology, Brilliant noted that equipment manufacturers need to set a benchmark for how they plan to adopt and integrate AI.

“We’ve got a responsibility as an industry to set some of the standards right now,” he said. “We’re on the cusp of exploration and early adoption. There needs to be some common

industry expectations and standards that make this as effective as it could be from the start.”

Cross-industry collaboration with manufacturers from other sectors, such as semiconductors, that have already implemented AI can save bakers a lot of grief as they begin to work through the technology themselves.

“The kinds of things [semiconductor manufacturers] are doing with the integrations of PLC programming, the ways they’re capturing data and making automatic adjustments are universal in manufacturing,” Brilliant said.

While some may be hesitant to begin using AI, the BIF team believes the time to learn about it — and embrace its potential — is now. The benefits can extend externally, too. Introducing AI also opens the door for baking companies to provide better service to customers.

“I see this being another piece of equipment to help us honor efficiencies and provide better value to customers,” Larson said. “If we can lower our costs down to the customer, we can provide a high-quality product for a lower price point.”

For leaders unsure of where to begin, Larson suggested taking time to test out the technology and identify colleagues who can carry the banner for what AI can do for the business.

Porter echoed that sentiment, noting that AI is the future of baking.

“If you want to be a relevant company and be competitive in the marketplace, you better embrace AI,” he said. “It’s coming, and there’s nothing to be afraid of.” CB

The Baking Industry Forum (BIF), formed by BEMA, assembles a group of bakers and suppliers each year to offer dialogue related to key issues in the baking industry. The pool of professionals is reputable for being well-versed in information and resource sharing.

The 2025-2026 cohort includes:

• Brandon Brilliant | president | AMF Americas

• Jon Miller | director of business development | A M King

• Matt Zielsdorf | global category manager — specialty bread and pastry | Middleby Bakery

• Mitch Lindsey | senior sales account manager| Burford Corp.

• Nick Magistrelli | VP of sales | Rademaker USA

• Ron Cardey | VP of business development | St. John’s Packaging

• Trent Wanamaker | sales VP | Cain Foods

• Chad Larson | VP and COO | Mel-O-Cream Donuts International

• John Mulloy | director of operations | 151 Foods

• Justus Larson | VP of operations | Franz Family Bakery

• Karl Thorson | global food safety and sanitation manager | General Mills

• Mike Porter | president and COO | New Horizons Baking Co.

• Richard Ybarra | senior manager of manufacturing engineering | Publix Super Markets

Tariffs aren’t just increasing costs; they’re also reshaping innovation.

BY MAGGIE GLISAN

Another day, another headline. “US Slaps 34% Tariff on Chinese Palm Oil” … “EU Imports Hit With 15% Surcharge” … “Canada and Mexico Tariffs Climb to 35%.” For commercial bakers trying to keep production running, it can feel like whiplash. Rising costs, supply chain headaches and unpredictable trade policy are no longer just news; they’re shaping daily decisions in the bakery.

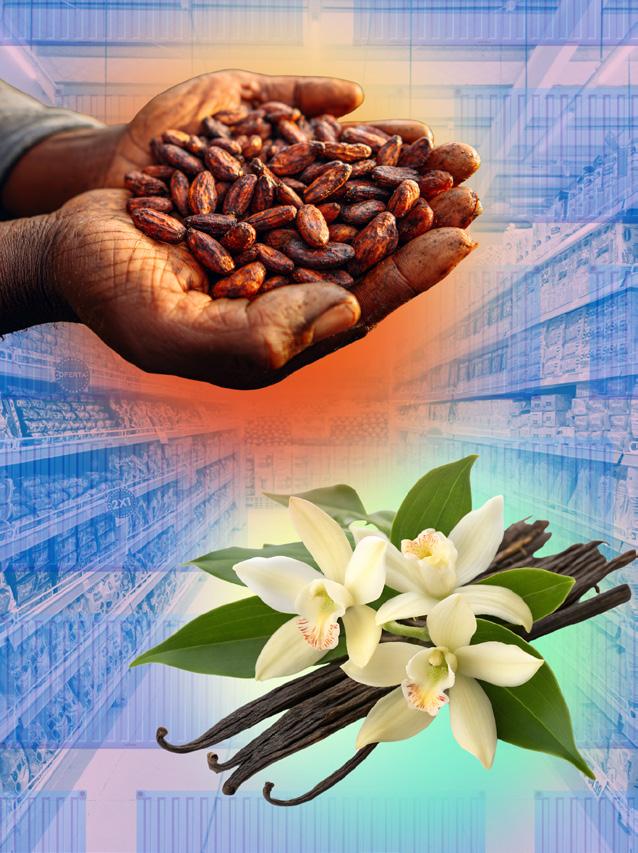

From ingredients like cocoa and vanilla to specialized machinery, the global supply chain affects nearly every aspect of bakery operations. But with tariffs on Canada and Mexico ranging between 25% to 35%, the EU at roughly 15%, and China at approximately 34%, the economics of the baking business are under strain.

According to Thomas Bailey, director of government relations for the American Bakers Association (ABA), these countries account for nearly two-thirds of US baking imports.

“The biggest impacts are being felt in ingredients, packaging and equipment, things bakeries rely on every day to keep production running,” he said. “Our research shows there is a $744 million estimated added cost for industryimported ingredients and supplies due to global tariffs.”

Shawn Marie Jarosz, founder of trade consultancy TradeMoves LLC, described the current tariff environment as turbulent and dynamic, forcing baking companies to become quasi-experts in trade regulations.

“It’s like drinking from a fire hose,” she said. “People have to become trade and tariff experts just to keep up, which takes time away from actually running their business.”

Tariffs are making it harder for American bakers to access the ingredients and equipment they need. Many essential items, including cocoa, vanilla, palm oil and tropical fruits, are not produced on a commercial scale in the US.

“Tariffs on these products limit access to essential inputs that American bakers can’t source domestically,” Bailey said.

Suppliers are feeling the trickle-down effects, too. John Howard, business development manager at Farinart, a Canadian cereal ingredient supplier specializing in customized blends and bakery mixes, described the initial rush by US companies to source locally in order to avoid import costs.

“It’s become a bit of a game of Whacka-Mole,” he said. “Everyone scrambled to adjust when tariffs hit, but now we’re seeing the dust settle, and many companies are realizing that food products are exempt from tariffs under the current United States-Mexico-Canada Agreement (USMCA), which is enforceable until 2026. Also, companies evaluating local options didn’t always find a better deal. After the initial scramble to source locally, companies are stepping back, re-evaluating strategies and exploring longer-term solutions.”

“Our research shows there is a $744 million estimated added cost for industry-imported ingredients and supplies due to global tariffs.”

Thomas Bailey | director of government relations | American Bakers Association

In some cases, tariff-driven demand for domestic ingredients has led suppliers to raise prices opportunistically, prompting buyers to re-evaluate their sourcing strategies, including returning to Canadian or other foreign suppliers.

Howard noted he’s seeing clients slowing down and evaluating costs. He stressed that open communication is crucial for navigating change, allowing suppliers and buyers to build solutions that protect innovation and budgets.

“It also opened the door for us to build even stronger relationships with our customers,” he said.

Howard encourages proactive conversations ahead of the USMCA review scheduled for July 2026, ensuring bakeries are aligned and prepared for any changes.

Tariffs aren’t just hiking up ingredient costs; they’re also putting a squeeze on bakery equipment. Jodi Guthrie, strategic growth specialist at Coastline Equipment, a food processing equipment manufacturer, described a “make it last” mentality taking hold across bakeries. Faced with higher costs for machinery and materials, many baking companies are choosing to repair and/or maintain existing systems rather than invest in new ones.

“Everyone seems to be asking, ‘How can we Band-Aid it?’” Guthrie said. “‘How much duct tape can we wrap around things to just keep the budgets in check and hope that the wind will blow in the right direction?’”

On the other hand, Eric Riggle, president of Rademaker USA, emphasized that uncertainty, not tariffs themselves, is the main factor in delaying decision-making.

“We’re not seeing projects get cancelled,” he said. “People still need to invest in automation because, on the other side of all of this, we still have a workforce issue that’s very real and not going away anytime soon. But it does slow down the decision-making process.”

To navigate this turbulence, Riggle highlighted the importance of education and communication.