ISSN 2305-9648

LIFT TRUCK COMPANY

explore

new business opportunities at africa’s leading timber exhibition

booK now!

for more information:

info@woodexforafrica.com +27 (0)12 751 7604

furniture & Kitchen production | forestry & sawmilling | Wood materials, machinery & Veneers tools, loggers and mobile saws | timber construction and supply | industry surface & treatment technologies many more timber related products, machinery and services.

New Product Launches | Live Demonstrations | Timber Talks | Great Deals | Competitions

21-23 March 2013 Gallagher Convention Centre | Johannesburg | South Africa

www.woodexforafrica.com proUd sponsors:

contents

CONTENTS

2

6

ED'S NOTE

8

contributors

14

woodex - 2013

18

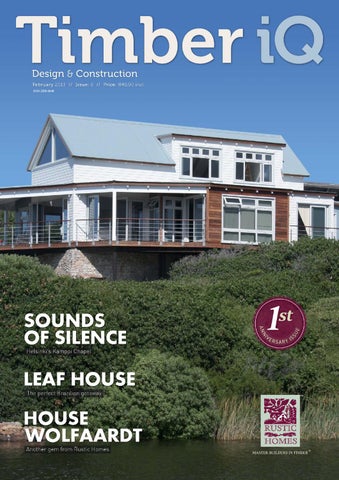

cover story - Lightness of being

26

industry insight - Timbersoft

28

architecture - Leaf House

38

events - HWZ InternationaL

44

furniture - Pierre Cronje

48

feature - novatop

52

architecture - Rossignol

60

dÉcor - Southern Eleven

66

research - Timber homes

FEBRUARY 2013 //

18

28

Extending the Benefits of Wood for Longer

L

onza Wood Protection’s approach to business is characterised by innovative products, valued brands, and exceptional customer service, including: · The broadest range of industrial wood preservative treatments in the world · Wood preservative treatments that make wood resistant to wood borer, termites, wood decay, moisture and fire · Engineering and marketing services, including a comprehensive guarantee program, to help customers grow · Broad global regulatory expertise and world-class toxicology and analytical chemistry skills · Customer solutions that contribute to the sustainability of their own products and services · Many products that satisfy green building and sustainability standards www.tanalised.com/sa Telephone: +27 (0) 39 315 8400 Email: woodtreatmentsouthafrica.arch@lonza.com

Lonza Wood Protection

contents

48

52

74 70

news - Hubtex

74

profile - Matriarch Equipment

78

news - Makita

82

architecture - Sounds of silence

88

news - ProNature

92

news - Wood

96

news - forester's boots

// FEBRUARY 2013

5

ED'S NOTE

Of paper children and letting go For many a writer, a body of work is often likened to the process of parenting - like a child, the written word is conceived, moulded, crafted, broken down and reworked into what one hopes will become an impressive, fully functional piece of literature and life.

T

hrough careful nurturing, it grows in depth and develops its narrative and character and, with precise pruning, it is cut back once more, hopefully to spring back from its confines to bloom more beautiful than ever. But one of the most difficult things for a writer, once all the pain of writing and re-writing is forgotten, is to let go, to send that ‘paper baby’ out into the public sphere to forge its own way in the world. In the month of March, Timber iQ celebrates its very first anniversary. Launched to an overwhelmingly positive response last year at WoodEX for Africa 2012, it is fitting that we observe this special occasion at the 2013 event, surrounded by our loyal supporters and raison d’être. It has been my greatest pleasure as the editor of Timber iQ to watch what was once a fledgling publication develop into a well-loved title that has carved, and continues to carve, its special niche in the marketplace. With every issue, Timber iQ continues to define its identity with one main goal – to showcase and celebrate timber in its vast number of forms and applications.

readers, contributors and advertisers for their unwavering support, their sincere and considered feedback and for the sheer joy and gratitude so many of them express at the existence of a publication such as Timber iQ. May we grow this publication together, so that it is reflective of the true potential of the timber industry in South Africa. With that, I welcome you to our 1st Anniversary issue, our biggest and most spectacular issue yet. Our readers can look forward to 96 pages filled with breathtaking local and international projects, superb industry insight, great products, services and advice. It is my hope that this issue of Timber iQ informs and inspires your appreciation for and investment in the remarkable material that is timber and that you share my pride in playing a significant role in shaping what has, over the past year, become a timeless companion to our respective timber-infused journeys. Here’s to you. And to Timber iQ. Jen

It is our audience that contributes to the evolving persona that is Timber iQ, and for this I wish to personally thank our

6

FEBRUARY 2013 //

21780

responsible

Forestry. An industry that does a lot more than grow trees. Forestry in South Africa is a R12 billion industry. It is the base of a local value chain that supports 750,000 people in rural areas. It generates substantial exports, helping to improve the country’s balance of payments. Most importantly, forestry is a responsible and sustainable industry, one in which Sappi is proud to be playing a leading role. Our more than half a million hectares of plantation forest are FSC™ (Forest Stewardship Council™) certified. We actively support a range of innovative environmental protection projects. We also create opportunities for local communities through tree-growing programmes and empowerment-driven ecotourism initiatives. For details, please visit our website. www.sappi.com

contributors

Contributors

THE TEAM Editor:

Jacques Cronje Jacques is a registered Professional Senior Architectural Technologist (Pr.S.Arch.T). While his architectural training is informal, having learnt by onthe-job experience, mentorship and self-study, he has degrees in building management and economics, a post-grad certificate in energy economics and has done several courses in energy efficiency and sustainable development.

Jennifer Rees 0861 727 663 076 119 8819 editor@trademax.co.za

Editorial Assistant Alex Struck alex@trademax.co.za 0861 727 663

Publisher: Billy Perrin billy@trademax.co.za 0861 727 663

Daniel Conradie Daniel is a Candidate Senior Architectural Technologist and freelance writer based in Cape Town. He is passionate about the design process and how the technology and materials employed are composed to express it. Jason Bakery lattĂŠs, sci-fi novels and Cape Town summers assist him in retaining his sanity and fervour.

Advertising: Zahida Mahomed zahida@trademax.co.za 0861 727 663 Angeline Martin angie@trademax.co.za 0861 727 663

Layout & design:

Get in touch

Craig Patterson craig@trademax.co.za

SUBSCRIPTIONS & DATA: Follow us @Timber_iQ

Like us Timber iQ

Visit us www.trademax.co.za

Celeste Perrin celeste@trademax.co.za 0861 727 663

Trademax Publications

Upcoming Events WoodEX for Africa 2013 21-23 March

ITFB Annual Awards 19 April

Knysna Woodworkers Festival 2013 24 – 29 September

8

FEBRUARY 2013 //

Tel: 0861 727 663 Cell: 082 266 6976 Fax: 0866 991 346 www.trademax.co.za P.O. Box 37053 Chempet 7442

DISCLAIMER The views expressed herein are not necessarily those of Trademax Publications. Although we have done our best to ensure the accuracy of our content, neither Trademax Publications nor Timber iQ magazine will be held liable for any views expressed or information disseminated in this issue.

WoodEx for Africa

GALLAGHER CONVENTION CENTRE

21-23 MARCH 2013 (STAND E1 - E6)

scm

group

EASY JET CNC NESTING MACHINE

JET

AXO FLEXA

SMARTEK EDGEBANDER Gluing

scm

Edge cutting

T/B Trimming

Scraping

MD-401 Buffing

group

THESIX UNIVERSAL CNC BORING AND GROOVING CENTRE

pointblankdesigns.co.za 031 305 3652

RIBEX VACUUM PRESS • 2 Models Eco & Robo • Single bed & double bed • Includes: membrane facilities • Magnetic Positioning points • High quality production capacity • Windows Based Real Time Os • Touch Screen

Magnetic positioning system, no jig system needed

0861 CMC GROUP

w w w . c m c m a c h i n e r y . c o . z a

VISIT ONE OF OUR SHOWROOMS • JHB • DBN • CPT

Luxury Timber Frame Constructors Country Timber Homes is a KZN-based timber frame and solid log construction company specialising in both full turnkey construction, as well as pre-built timber home kits. Turnkey: We specialise in high quality, luxury timber frame homes, but are also able to assist with first-time homemakers and smaller construction projects. With our experienced building teams, design capabilities and full project management services, we can offer you a tailor-made solution from start to finish. We also undertake loft conversions, second storeys, alterations and additions. Pre-built timber homes: Ideal for remote locations, as well as for DIY enthusiasts, we supply all the pre-constructed structural components, allowing you to complete the finishing touches with your own personal feel. Pre-built home kits are available in standard one- to five -bedroom homes designs, either as timber frame, post-and-rail or solid log formats. Easily transportable and assembled, our pre-constructed kits are available throughout South Africa and are well suited to the export market.

Environmentally responsible and sustainable, wood is good and it’s the better way to build! Environmentall

For more information contact: Dave 0718862045 dave@countrytimberhomes.co.za

www.countrytimberhomes.co.za Brad 0833915605 brad@countrytimberhomes.co.za

Physical address: Unit 4, Halstead Park 15 Halstead Road Mkondeni

RECON THATCHERS OFFERS YOU: • Thatch roofs for houses, game lodges and lapas. • Recon Thatchers construct thatch roofs to any shape and size. • Specialized repairs and rethatching to existing roofs. • Recon Thatchers is an approved applicator of Micon Coatings namely Thatchsayf and Thatchbor flame retardants. Micon Thatchsayf is applied to existing roofs to be fire retardant for seven years. For new thatch roofs Recon Thatchers also have its own plant where thatch grass is pretreated with Thatchbor. This pretreated thatch grass keeps the flame retardant properties for ever until the roof must be rethatched. • Recon Thatchers is a founder member of the Thatching Association of South Africa (TASA). • All our structures are build with SABS approved Tanalith treated poles. The thickness of the poles, nuts and bolts for the structure is according to the Thatching Assosiation of South Africa’s standards (SANS10400). • The owner Bertus Nieuwenhuis is currently the vise chairman of TASA. • Recon Thatchers is in business for the last 29 years under the same name and management.

Let our professional artisen at RECON THATCHERS improve the character and value of your property with Thatched roofing that will last year after year.

SINCE 1983

woodex

All set for WoodEX for Africa Final preparations are under way for WoodEX for Africa, which will be held at Gallagher Convention Centre in Midrand, South Africa, from 21 - 23 March 2013. With local and international exhibitors and visitors in attendance this event will definitely be a highlight on the timber trade agenda for the year.

S

tephan Jooste, Director of WoodEX, says the event’s visitor promotional campaign is rolling out with advertisements and articles in a variety of industry publications. These advertisements will soon be followed by a radio campaign, street posters and newspaper advertisements. “We are very grateful for the support from our project sponsors, the industry associations, our media partners and our exhibitors. WoodEX is the ideal platform for wood and woodworking professionals to be on the frontier of the timber industry and to network, and we look forward to an excellent event this year.” Highlights at WoodEX for Africa 2013 include Timber Talks, a number of short seminars which will provide a dynamic and interactive learning experience to visitors at the event; Timber Games – a thrilling competition during which South Africa’s most skilled chainsaw operators and wood carvers will showcase their skill in speed cutting and carving competitions, as well as demonstrations by celebrated DIY guru and television personality Riaan GarforthVenter, better known as ‘Die Nutsman.’ With WoodEX fast approaching, most of the exhibition space has already been booked and exhibitors interested in still securing a stand should do so urgently. The WoodEX for Africa exhibition will feature exhibitors showcasing innovative timber and woodworking products and services such as woodworking machinery, decking, flooring, structured timber, timber treating, saw milling and logging, pulp and paper manufacturing and wood material and veneer production.

14

FEBRUARY 2013 //

Booth # A12

Power of One System to Design, The

Quote, Engineer & Build it All...

What Do You Want to Build Today? Powerful, easy to use AutoCAD based design & manufacturing software, providing you the tools needed for 2D & 3D design, estimates, cut lists, reporting, optimization, scheduling, project tracking, CNC machine code, CAD/CAM and just about everything else you need for manufacturing. From wardrobes, commercial cabinets and store fixtures to residential kitchen and bath, Microvellum gives you the power to build it all from one software application.

www.microvellum.co.za 011 312 0677 | info.za@microvellum.com

ď ą

woodex A word from our sponsors Justin Berry Executive Director PG Bison “PG Bison’s own success is inextricably linked to the growth and development of the industry in which it operates and we are therefore very proud to partner with WoodEX for Africa. As the leading manufacturer and primary upgrader of timber related products it makes perfect sense for us to become involved in WoodEX – the leading timber trade show in South Africa - as WoodEX creates an excellent marketing and networking opportunity for the timber trade to meet potential clients operating in this large market. We are very excited about our WoodEX partnership and we look forward to seeing the event grow to one of the leading timber events in the world.”

Jean-Jacques Oelofse Wood-Mizer Africa & South Africa’s Regional Manager/Managing Director “Wood-Mizer is proud to be associated again with WoodEX for Africa 2013, its presence at the expo as both an exhibitor and also as one of the main arena sponsors informed by its view that WoodEX is South Africa’s premier timber event, the occasion serving as a key opportunity for a cross-sectoral review of the latest services, products, innovations and thinking that has relevancy and bearing on the timber industry’s current and future direction. This, plus the successes achieved by Wood-Mizer during 2012 has prioritised its presence at the 2013 event. We look forward to meeting both existing and new customers at WoodEX 2013 with the event and our presences there spurring and improving sawmilling activity locally and on the continent for the benefit of all.”

Karl Hinteregger Owner, Hin-Tech “Hin-Tech is proud to be supporting the Timber Games at WoodEX for Africa. We see WoodEX for Africa as an excellent platform for the development and exposure of this unique sport and we are excited to be associated with these games. Just as Hin-Tech takes pride in building strong, reliable machines, we are honoured to be able to give something back to the industry and to support South Africa’s most skilled chainsaw operators and wood carvers.” iQ

For more information about WoodEX for Africa 2013, including exhibition packages and sponsorship opportunities, visit the WoodEX website at www.woodexforafrica.com.

16

FEBRUARY 2013 //

Following the great success of the 2012 Knysna Woodworkers Festival, bookings for exhibition space at the 2013 Knysna Woodworkers Festival are now open! Calling on local and national timber and timber-related industries, as well as associations to exhibit at this specialised event! Maximum exposure for all sponsors and exhibitors via extensive media coverage and premium on-site advertising!

Exhibitors to include: • • • • • • • • • • • • •

Arts & Crafts Furniture Manufacturing Timber Frame Building Timber Treatment & Preservation Paints, Coatings & Protective Sealants Forestry & Sawmilling Woodworking Machinery (Industrial & DIY) Power Tools Fastening Systems Handles, Hinges & Accessories DIY Training & Education And much more!

For more information about exhibiting at the Festival or for our premium sponsorship packages, please contact Johan Nel: (c) 073 394 0057 (e) info@knysnawoodworkers.co.za

www.knysnawoodworkers.co.za

cover story

Lightness of being Resting lightly in a fragile landscape, House Wolfaardt embraces the charming recollections of holidays on the beach long ago here in a family home as gentle on the eye as it is on the surrounding landscape.

cover story

B

uilt on a portion of the Wolfaardt family’s Onrus plot that presented numerous technical and environmental challenges to the Rustic Homes design team, House Wolfaardt is testament to the creativity and tenacity of the team, and more specifically to designer, Bobby Welman, and project manager, Johannes Mathewson, who were tasked with managing the construction design. The result: a contemporary, open, airy beach house. Ingrid Wolfaardt, writer, mother, successful entrepreneur and proud owner says, “Our brief to Rustic Homes was interpreted in a clean, fresh, uncluttered way, and how delighted we are in the way the team incorporated quality components and finishes, such as aluminium and beautiful timbers, most notably our solid chestnut flooring.” Pieter Silberbauer, CEO and founder of Rustic Homes says, “The house incorporates many traditional features that have stood the test of time. Walk in and you cannot fail to sense that here is something unique - not just because of the setting,but because of how everything works together.” Ingrid insisted on bringing something special and personal to the house, so Pieter and team were briefed to include in their planning Ingrid’s eclectic collection of recycled doors, bathroom fixtures and detailing, all reminiscent of the beach houses on the Wild Coast where, as a child, Ingrid spent so many perfect holidays.

Challenges: The sensitivity of the plot on which House Wolfaardt was built was of particular concern. Falling within 100m of the high water level, constrained by height restrictions and being home to a protected Milkwood forest, the build demanded clever planning and sensitive detailing.

Planning: Due to the tight restrictions presented by environmental concerns, approval was delayed. The Wolfaardts, however, have a glass-half-full outlook on life, so Ingrid took it all in her stride. “In hindsight, the delay gave us more time to mull over the design and to aim for perfection in every detail. Extra time made room for thought, enabling us to resolve issues such as the utilisation of space and to include all those special touches that weren’t there initially. We took time to study the terrain and we worked with what we had here… We used the time well.”

Rocks: The foundations, which had to be set in existing rock, presented a challenge met by suspending the house using brick piers on the rock, as well as a plinth wall of brick. This wall and the perimeter walls were clad in stone sourced entirely whilst excavating the foundations.

// FEBRUARY 2013

19

cover story

Milkwoods: Beautiful and endemic to our coastal areas, Milkwoods are protected. Therefore, it was important to the clients and environmental authorities alike that the Milkwood forest surrounding the house remained undamaged during the build. An Environmental Impact Assessment was conducted and Nature Conservation was consulted. “Environmental Affairs were involved from the moment we started,” says Ingrid, “We invited them to join us on site on day one, and that was a great move, because we learned what needed to be shifted or moved right at the start of the project. My husband, John, has planted many more Milkwoods and already lush new growth is evident, thanks, in part, to the shelter from the wind which our new home provides. ”

20

FEBRUARY 2013 //

Recycled sanitary ware and accessories were selected by the Wolfaardts to give an aged look to their new home, keeping it from appearing too clinical and modern.

cover story

// FEBRUARY 2013

21

cover story

Detailing: Timber Timber devotee, Johannes, says, “Environmentalists will always prefer a dry structure, so timber frame construction was ideal for this house as it has a far lower impact on the environment than do more conventional methods. When building in sensitive areas, timber is always the preferred option. Building with timber meant that the main structure of the house could be engineered and completed off site in a safe, controlled environment at our Grabouw factory.” Treated pine was used for much of the structure. In many areas the beams were left fine sawn and exposed with a lime washed finish. This contrasted beautifully with the painted timber ceilings and the characterful ‘wormy’ chestnut floors supplied by Bestwood Flooring and selected by Ingrid and John Wolfaardt. Decking was completed using Balau and the external cladding with Jarrah, a sturdy and stable timber once used in the manufacture of railway sleepers and requiring little or no maintenance. House Wolfaardt’s classic beach house feel was completed with grey corrugated aluminium for roofing and some of the external cladding. Low maintenance stainless steel and/or aluminium fasteners were used. The handrails are galvanised and, with time, will weather to complement the soft, natural appeal of the house.

22

FEBRUARY 2013 //

cover story

cover story

Insulation Home to an abundance of light, the house is well connected to its surroundings with beautiful views guaranteed by the extensive use of double glazed glass, which also helps regulate the ambient temperature. The living area and mezzanine/gallery bedroom form a double volume space. This not only helps regulate the temperature but also highlights the home’s easy flowing and relaxed character. State-of-the-art insulation in floors, walls and ceilings and double glazing quieten things down dramatically and the Wolfaardts are enjoying an internal climate comfortable in all seasons. Ingrid agrees, “I find the insulation excellent. I don’t think I will ever need a kaggel!”

Flooring Internal flooring was completed using solid ‘wormy’ chestnut. True to the clients’ appreciation for honest detailing this characterful timber adds great charm to the interior, to such an extent that the floors have become a major feature of the house, warm and tactile as they are under foot. “All the contractors that Pieter and Johannes worked with were special; the entire process was a happy, collaborative one. Many people discover that building a home can turn out to be an extremely stressful experience, testing the best of relationships. However, we loved how the Rustic Homes team provided John and me with an opportunity to be really creative. It was just fabulous and best of all what fun we had!”

24

FEBRUARY 2013 //

Rustic Homes is firmly established as a leading player in the field of timber home building, constructing homes that are built up to a standard and not down to a price. The Rustic Homes team never forget the importance of the client’s input from day one of the planning until handover and beyond. iQ

For more information (t) 021 859 5193 (f) 021 859 3646 (e) info@rustichomes.co.za (w) www.rustichomes.co.za

GREAT CAPE LANDMARKS ARE STILL BEING CREATED...

Given the beauty and versatility of timber, Rustic Homes’ architects and designers continue to create landmark homes in the Western Cape. Having pioneered timber construction here, we have perfected the technology that makes our bespoke-built homes immune to the vagaries of our climate.

...HERE IN THE VALLEY OF THE MARSH ROSE

Unrivalled finish and craftsmanship. It all starts here at our factory in Grabouw’s beautiful Valley of the Marsh Rose: a unique workplace where craftsmen pursue their passion for building homes that people love to live in... A place that welcomes clients to experience for themselves excellence at work, and to meet the people responsible for the faultless fit and finish of every panel and beam of every Rustic Home.

Visit www.rustichomes.co.za

Email info@rustichomes.co.za

Call Mel (Mondays to Wednesdays) on 021 859 5193

industry insight

Efficiency and Productivity in the Timber Industry With the rising cost of electricity, recent minimum wage increases and high raw material cost threatening the existence of the timber industry in South Africa, the time to take a critical look at efficiencies and productivity is way overdue. Words: Henco Viljoen, Timbersoft cc

G

one are the days where quantity took precedence over quality and effectiveness. To survive, the maximum return on investment must be achieved from every single log entering the gate. To achieve this, sawmilling will have to raise the bar in efficiency and productivity.

The main areas in which improvements are possible: 1. Recovery 2. Electricity 3. Labour efficiency

Recovery: Recovery is not only about improving gate-in-togate-out recovery, but also about improving each element in the process. The key here is being able to identify where improvements are possible. However noble it is to chase a good gate-in-togate-out ‘bookkeeper’ recovery figure to keep the board of directors happy, this normally comes at a price. True efficiency is to get the sawn lumber through the process without having to rework too much in an attempt to recover ‘recovery.’ Each time a piece of lumber has to be sawn shorter, joined to make longer, or planed down to get a flat surface, not only are cost added, but also recovery is lost. True recovery should be measured by an increase in bottom line without an increase in production. The picture above is a slight exaggeration, but gives a good picture of where money is lost. With modern sawing machines and technologies implemented it has become very easy to cut boards to an accuracy of 0.1mm.

26

FEBRUARY 2013 //

Coupled with on-line sawing pattern optimization software to get the most out of every log. The sawing process is very visual and easy to correct if things start going wrong. The next link is the drying process. After sawing, this area is probably the biggest value- and cost-adding factor to the sawmilling process. The problem is, it is not as visual as sawing, and the end result including success or failure is only realized when the lumber stack is de-stacked after a 12-24 hour cool down period. By now, the recovery outcome can only be altered by adding more cost. The true benefits of managing the drying process with the same level of expertise and focus as the sawing process is completely under-realized in most South African sawmills. Specialist focus is required to get the balance between speed and quality right in each kiln and can only be achieved if a number of factors are done right every time.

They can roughly be summarized as: 1. Preparation – Sawing accuracy, board dimension, stacking procedures 2. Process control – Airflow, energy distribution and management, humidity control and venting

industry insight 3. Maintenance – Electrical, mechanical, instrumentation and structure 4. Schedule optimization – optimally managing the condition inside each kiln 5. Monitoring, quality control and corrective action If any of these are left out, or not managed properly, drying time and quality is negatively affected.

In kilns, the use of variable speed drives can dramatically reduce the electricity bill. The power required to drive the fan varies as the cube of the speed, e.g. if the fan speed is doubled, the power required to drive the fan increases eight times; if the fan speed is trebled then the power increases by 27 times. It is not necessary to run the fans at full speed throughout the drying process, only during the early stages when there is still a lot of moisture to move. Reducing fan speed to 80% can reduce the power required to 50% without reducing drying time.

The spin-offs of proper drying can be summarized as follows: • Reduction in drying time, resulting in a drop in electricity bill • Reduction in drying reject rate, increasing recovery and decreasing rework cost • Increase in average selling price • Fewer finger joints per length, resulting in less glue usage • Flatter drying allows for smaller set up size in wet mill, less allowance for warping and planing - increasing recovery • Less planing in the dry mill will draw less current, saving electricity and increasing the time between blade sharpening. This will also result in less wear and tear on machinery and hence extend machine life.

Electricity: Electricity can be saved by working smarter. In the sawing process, thicker saw kerf draws more current. Thinner kerf saws however tend to saw skew at higher feed speeds. It is sometimes possible to decrease feed speeds slightly and still make target production. Thinner saw kerf will save electricity and increase recovery. In sawmills where high kW machines with high current spikes operate, Power Factor Correction can be implemented. Power Factor Correction has been known to reduce the electricity bill by as much as 40-50%

Labour efficiency: People must earn their keep. In a perfect world, through training and employing better qualified people, the efficiency should improve. In the real world, however, labour unrest and minimum wages have been increasing drastically without increasing output. The problem with huge minimum wage increase is that while it increases the low down workers' salaries by ± 50%, it will create unhappiness with the higher paid labourers also wanting a greater percentage of salary increase, increasing the payroll by a big margin. I envisage large scale automation and mechanization in the not-so-distant future to counter the rising labour cost and lower efficiency. Sadly this will also result in job losses. The message is simple: Work smarter and more efficiently. Henco is a Saasveld B.Tech - Wood Technology graduate, a Control Systems and Microsoft Systems Engineer. Timbersoft cc specialises in optimising kiln drying, as well as technical assistance and custom automation in the sawmilling process. See our advert on page 81. iQ

Up to 6m long - 250 x 250 mm or bigger! Cut to order. Fully pressure treated. Cheaper than you think. Phone for a quote or see our website. Tel: 013 751 3021 / Mobile: 082 785 8215 / Email: pullscar@mweb.co.za

www.pullscar.co.za

// FEBRUARY 2013

27

architecture

Leaf House With a warm and humid climate for the largest part of the year, Brazil attracts many tourists and prospective home owners in their tireless search for the perfect getaway. Today, it seems, we have discovered one of them. Words: Daniel Conradie Photography: Š leonardo@finotti.com Images courtesy of Mareines + Patalano Arquitetura

28

FEBRUARY 2013 //

architecture

L

ocated in the municipal district of Angra dos Reis (a short drive South of Rio de Janeiro), a popular tourist destination on account of its tropical climate and unscathed beaches, the 800m2 beach house in question makes no attempt at conforming to the neighbourhood's aesthetic standards. Instead, a rich organic structure rests on a perfectly manicured site, allowing the viewer to move around it freely and absorb its complex geometry. Leaf House is an excellent architectural precedent when taking into account its response to the area's warm and humid climate. The standard approach to designing a building within an area susceptible to high humidity is to maximise ventilation by encouraging the movement of air throughout the building – an approach the architects followed diligently. The architects and the client were in mutual agreement with the premise that a tropical beach house should primarily serve to enhance the dialogue between nature and man, and, where possible, to blur the boundaries between them. As a result of this preoccupation with the definition of a nondefinite space, the final product appears to be more of a threshold than an actual structure. In essence, the design is a reflection of Brazil's vernacular Indian architecture, not as much a literal rendition thereof (in terms of form), but more in its particular approach to the material selection. Vernacular architecture or an approach to building design inspired by local conditions - which can include climatic conditions, local culture, materials, and techniques - develops out of the desire (or limitation) to only use local materials. The stone used in this project, for example, was collected from the site and incorporated into the material palette. Viewing the ground storey floor plan, the house is composed of 6 'leaves' that radiate from a central point. Each space is allocated a particular leaf and its extent is wrapped in a skin of sliding glass screens. The result of this particular strategy is a floor plan consisting of a punctuated series of enclosed pavilions, all unified beneath the commanding roof element.

// FEBRUARY 2013

29

architecture

architecture

Movement in between the pavilions serves as a reminder to the viewer that the house takes no stance in defining an interior. It was part and parcel of the architects' intention to remove any residual areas in between these primary volumes in an attempt to maximise the flow of air throughout the house. The downstairs living spaces are populated by large furniture pieces and traditional Indian hammocks, all of which are dressed in natural fabrics in pale white and cream tones. Colour is introduced in the palette through the employment of various tropical plants. Completing the composition, a snaking pool weaves through the space, and where it meets the central formal dining room passes through it and becomes a pond for aquatic plants and fish. Upstairs, four bedrooms and bathrooms hover over the spaces below, each bedroom enclosed within its own pod. The bedroom interiors employ a very dramatic colour scheme of polished wooden floors, wood-clad walls and weaved reed ceilings. Set against this somewhat static and singular backdrop, airy fabrics in rich colours provide privacy and movement to the spaces.

// FEBRUARY 2013

31

architecture

Ground floor plan: Scale 1: 200 1. pool veranda 2. fireplace 3. rear veranda 4. dining room 5. home theatre 6. suite 7. Closet 8. bathroom 9. kitchen 10. store room 11. washbasin 12. swimming pool 13. pond 14. stairs

32

FEBRUARY 2013 //

Selectively sourced hardwoods from around the world

Eco Timber Traders is a KZN based timber merchant specialising in Exotic Hardwoods. Eco carry over 40 different species of timber which are supplied in large or small quantities to the furniture and cabinet industry, as well as joiners, shopďŹ tters, the kitchen industry and anyone that uses quality hardwoods. Eco Timber Traders supports suppliers that offer FSC timber and timber that comes from well managed, sustainable plantations. Call them for all your Hardwood, Softwood, decking, ooring and natural edged timber slab requirements.

Contact Us Tel: +27 (0) 31 701 7023 Fax: +27 (0) 31 701 9576 Email Hans: hans@ecotimbertraders.co.za Email Rob: rob@ecotimbertraders.co.za

architecture Undoubtedly the roof is the star of the ensemble - an awesome eucalyptus structure, both in terms of its scale and sheer complexity - and is dressed in pine shingles. Its form evokes images of billowing sails – an appropriate metaphor, considering its coastal context and the design's intent to maximise natural ventilation. Most commonly, the roof element of a building is simply left as an exercise of capping the spaces, shielding it from the weather. In this particular case, however, it is the roof that serves as the primary generator for the form of the building and provides the framework for the spaces it encompasses. The roof's overbearing influence amplifies the intent of blurring the boundaries between the interior and exterior realms, as well as serving as an effective shield for the contents from the harsh tropical sun. The unique geometry of the roof also directs a large portion of rainwater to its centre, where a large steel post funnels water into a reservoir where it is used for flushing toilets and irrigation. It seems that the archetype for a successful tropical beach house, or at least one seemingly successful interpretation thereof, should be to strive towards it not being a house at all. The Leaf House is merely a large cover, enhancing the existing conditions, eliminating the undesirable and providing the perfect venue for the ultimate getaway. iQ

Second floor plan: Scale 1: 200 1. mezzanine - open circulation 2. suite 3. closet 4. bathroom 5. open to below 6. stairs

34

FEBRUARY 2013 //

architecture

Quick facts Location: Angra dos Reis, Rio de Janeiro, Brazil Completion date: 2008 Project: Mareines + Patalano Arquitetura Architects: Ivo Mareines Rafael Patalano Paula Costa Flรกvia Lima Rafael Pretti Construction: Laer Engenharia

36

FEBRUARY 2013 //

events

HWZ International's 3rd Annual Wood Conference inspires and informs

Held at the Cape Town International Convention Centre on the 8th of February, the Conference presented a unique opportunity for the exchange of ideas, information and inspiration on the topic of wood, in its various states and applications, as a viable and natural building material.

W

ith the aim of uniting anyone in the industry with a connection or interest in wood as a sustainable building material, the Conference also provided a space for highly targeted, effective networking, as well as an opportunity for international experts to address and share developments in the wood industry abroad. With a heartening welcome from Irene Flückiger, the Consulate General of Switzerland, and an introductory speech by Thomas Rohner of cadwork, Jacques Cronje of Jacques Cronje Timber Design delivered a discussion and analysis of ‘Timber Homes in South Africa: past, present & future.’

Jacques Cronje, registered Professional Senior Architectural Technologist.

Taking a look the history of timber home building in South Africa, as well as current attitudes towards timber home building in the country, Cronje concluded that although timber home building forms a small percentage of the overall home building market in South Africa, the good news is that attitudes towards the material are positive, especially among those who have experienced living in timber homes, and that there is much room for the popularity of this material to grow.

Thomas Rohner of cadwork - organiser of 3rd Wood Conference.

38

FEBRUARY 2013 //

events Jirí Oslizlo, chairman and CEO of Agrop Nova A.S. in the Czech Republic and Switzerland, highlighted the many benefits of using wood in buildings. Making reference to Novatop products and systems that boast exceptional quality, innovative composition, for superb energy efficiency and climate control, and are prepared with precision, Oslizlo affirmed that timber is a unique material that can fulfil the aesthetic, sustainable and design-flexible aspects we have come to require of a building material.

Jirí Oslizlo, Chairman and CEO of Agrop Nova A.S. in the Czech Republic and Switzerland.

Project manager at WSP, Johannesburg, Mel Barton, took to the stage after Oslizlo to elaborate on the energy and thermal performance of the Novatop House, based in Cape Town. Built specifically to undergo performance testing, the Novatop House’s resultant performance throughout the year has been compared with that of a typical existing South African construction for a dwelling with no insulation. It was found that the Novatop House required approximately eight times less power to maintain optimal comfort levels, representing a significant saving over time to potential homeowners. Reverend Otto Bernd Kohlstock is the director of iThemba Labantu Lutheran Community Centre, a church-based NGO with an outlook that underlines the importance of coupling the written word with sincere and meaningful actions. Among many others, the Centre offers the disadvantaged people of Philipi free access to nutrition, education, health care, and empowerment through income generating and skills development projects.

Mel Barton, Project Manager at WSP Johannesburg.

Reverend Otto Bernd Kohlstock, Director of iThemba Labantu Lutheran Community Centre.

Luyanda Mphahlwa.

Luyanda Mphahlwa, introduced by Kohlstock, is an architect, and an advocate for African-inspired design and its role in “re-envisioning South Africa’s post-Apartheid architectural landscape.” (currystonedesignprize.com) Mphahlwa highlighted the role of timber as a sustainable building material in his contribution to the Design Indaba’s 2007 Freedom Park 10 x 10 Housing Project. Deciding to create a double-storey structure from timber and using sandbag construction as wall fillings, the project, drawing from African-inspired design, came to involve the community. Andy Raymond Horn, Founding Director and Principle Architect of Eco Design Architects & Consultants, delivered a talk on ‘Practicing Environmentally Responsible Timber Sourcing & Treatment,’ underlining the benefits of harvesting and treating timber locally, using non-toxic natural treatments and finishes, indigenous plant recipes and moon phase harvesting methods for improved stewardship of the planet.

Andy Raymond Horn, Founding Director and Principle Architect of Eco Design Architects & Consultants. // FEBRUARY 2013

39

events Michael Louw, an architect who currently teaches second year Technology in the BAS programme at the University of Cape Town’s School of Architecture, Planning & Geomatics and runs the annual Imizamo Yethu platform design-build project, presented on the journey of his career and its significant connections with timber. Louw draws on timber’s capacity to be reused and recycled and the importance of this factor in the Thesen Islands development, as well as some of his students’ remarkable responses to design briefs using wood, to illustrate the dynamism of his colourful career and the flexibility of timber as a material with which to design and build. Regional Engineer for the National Home Builder Registration Council, Anton Marais discussed the role of the Council in timber construction and its role in protecting consumers, promoting and maintaining quality standards in the industry, and building capacity of home building and housing consumers with specific emphasis on the historically disadvantaged. Making reference to the benefits of the Council, as well as the services on offer by the Council, Marais highlighted the regulations that govern timber construction and the importance of adhering to these. Chris Haring, President of the Haring Group’s Management Board discussed, ‘Wood as a creative and job-creating material in Africa.’ Haring highlighted the importance of adding value within the (African) country by processing raw materials there, instead of exporting them, resulting in a wealth of meaningful benefits for the producing country (Gabon, for example), including skills and industry development, which go hand in hand. Haring says, “Our activities in this country (Gabon) therefore constitute entirely intelligent and self-supporting development assistance.”

Michael Louw, architect and teacher of Technology in the BAS programme at the University of Cape Town’s School of Architecture, Planning & Geomatics.

Regional Engineer for the National Home Builder Registration Council, Anton Marais.

Haring also mentions, and showcases, to an extent, the work of Master Swiss Carpenter, Marc Lüdi, saying, “Today, he is practising and developing housing structures and wood interiors at a very high-end finishing level here in Cape Town.” Furthermore, making reference to the Saldome in Rheinfelden, a spectacular dome-shaped structure for the storage of approximately 80 000 tons of salt, Haring commented that, “The three interlocking (timber) arch systems have an impressive natural aesthetic appeal and are clearly effective as supporting structures.” The Saldome has a diameter of 93m, is 31m high and employs the use of about 1 500m3 of untreated timber.

Chris Haring, President of the Haring Group’s Management Board.

Katharina Lehmann, Chairman of the Board of Directors and Chief Executive of Blumer-Lehmann AG, Holzwerk Lehmann AG, BL Silobau AG and Erlenhof Energie AG, discussed the process of building TAMEDIA, an office building for a publishing house in Switzerland, as a prime example of urban timber construction. Lehmann highlighted the benefits of timber as a versatile material with which to plan, work by machine or by hand, erect and assemble for a final product that is a truly breathtaking world class feat. TAMEDIA stands testament to the incomparable flexibility of timber and the sheer beauty of a sizeable project completed entirely in this material.

40

FEBRUARY 2013 //

Katharina Lehmann, Chairman of the Board of Directors and Chief Executive of Blumer-Lehmann AG, Holzwerk Lehmann AG, BL Silobau AG and Erlenhof Energie AG.

events HWZ International’s 3rd Wood Conference reiterated the importance of timber as a viable and sustainable building material, as well as the need to make use of timber resources more effectively and with greater care. As a modern building material, wood offers exceptional possibilities with limitless design potential and great aesthetic appeal. iQ

3rd Wood Conference delegate feedback: First of all, I take this opportunity to commend you for organising and excellent event with the Third Wood Conference. I must admit that it was the best seminar I have attended - from the speakers to the delegates and not to mention the food. Everything was international class! Besides gaining valuable knowledge, I also made acquaintance with delegates from the UK, Switzerland and other parts of Europe, who flew down especially for this event. This event was also great for networking! Once again, thank you for organizing this great event, including the hospitality. I am looking forward to the next one! Sam Ahmed (Pr. S. Arch. T.) Once again I found the conference most informative and well worth the time and effort to attend. Many thanks for your input in sorting out the arrangements. Arthur Coombe-Davis (Quantity Surveyor) Thank you so much. I thoroughly enjoyed the conference, and I would like to see more architects speaking on the role wood can play in the more impoverished areas of our beautiful country. Although Luyanda didn’t speak for long, it was the start of a very inspirational and thought-provoking talk. Ryan van der Vyver (Architect) I want to tell you how much I enjoyed your excellent conference – very interesting and well organised. Thanks a lot! See you at the next one! Thomas Leach (Architect) A really great, well organised conference. Frank Millenaar (Architect)

For more information, please contact: Cell: 076 401 9120 Email: capetown@hwzinternational.com Web: www.hwzinternational.com

42

FEBRUARY 2013 //

The HWZ International 3rd Wood Conference team.

Optimising the Future Donald Fuchs machinery

H: : : B :

S: HPP ::: :: ::

W

W

AB :::

B::::t A

:ti:: :::: C

To ďŹ nd out more::::::::::::::::::::::::::::::::::: Follow us on facebook at:

Tel: +27 (0) 12 653-5111 Fax: +27 (0) 12 653-5014 www.altstructures.co.za

Alternative Structures stocks the popular Easy Clip hidden deck fastner. Over 8 million Easy Clips have been sold to date!!

Whenever you build a deck, think: We offer a wide variety of brackets for all your pole & plank fastening requirements, as well as a large range of heavy duty hinges for those tough applications! Whenever you cut, drill or machine Treated Poles you need to reseal the timber. Please contact us for more information

FullCircle001

Proud member of :

BHX::::

furniture

Designer furniture icon, Pierre Cronje, announces the opening date of his new showroom in Johannesburg Pierre Cronje reveals the date of the opening of his exciting new Kramerville showroom to be 11 April 2013. He had planned to open shop late in March 2013, but, considering the school holidays over the Easter period, decided to postpone the event to Wednesday, 11 April 2013.

T

he new showroom’s location, no 16 Desmond Street, Kramerville, is the former Fabric Library building, known to many interior designers and décor enthusiasts. The new Pierre Cronje venue, with its 700m2 showroom capacity, will be ideally suited to showcase the large variety of solid wood furniture pieces that have become iconic in distinguished homes, restaurants and hotels in South Africa. Pierre Cronje says that the Kramerville showroom will not only boast finished Pierre Cronje pieces, but customers will be able to have individual solid wood items designed and made by hand to their specifications.

44

FEBRUARY 2013 //

He says an element of the Pierre Cronje factory will shine through in the design of the showroom, educating visitors on Pierre Cronje’s South African manufacturing heritage. Pierre Cronje’s furniture pieces reflect not only their design, but also a lifestyle. Continuing on the feel of the showroom in Johannesburg, he says, “The furniture will be the centre of attention in the new showroom, with the wood speaking for itself.”

South African made CNC Machines

CNC MACHINES TRAINING SUPPORT

LARGE FORMAT WITH VACUUM TABLE

CUSTOM WOOD CARVING CNC ROUTER

3D MACHINING

3D MOULD MAKING

STANDARD WOOD CUTTING CNC ROUTER

Custom, standard and industrial CNC routers made to order UNI-CAM CNC MACHINES are fully designed and manufactured here in South Africa. Whatever job you want to do, or machine you need , we will build it for you at prices you can aaord. At UNI-CAM CNC SYSTEMS, our goal is to provide you with our best machine, professional service and ongoing technical support. Our professional staa are keen draw on their extensive knowledge and experience to help you get the most out of your production with your UNI-CAM CNC ROUTER.

We make CNC...ABC!

www.uni-cam.co.za

Tel: +27 21 7056081 sales@uni-cam.co.za

For personal attention call... Marc on 083 456 2798 Unit 25, South Cape Industrial Park, Leo Rd, Diep River, Cape Town 7800

furniture

"The furniture will be the centre of attention in the new showroom, with the wood speaking for itself."

In celebration of the new showroom, Pierre Cronje plans to offer irresistible discounts on items in the showroom for three weeks from 11 April 2013. The successes of his previous sales in Cape Town show the popularity of the Pierre Cronje brand and the desire to own the exquisite wooden designer pieces. iQ For more information, visit www.pierrecronje.co.za.

46

FEBRUARY 2013 //

NLA Imported Timbers opens a Merchant Division NLA has been importing and distributing timber, board, composite decking and related products into South Africa and neighboring countries for over 26 years. With a combined experience of over 120 years in the timber industry, NLA have developed solid relationships with reputable and reliable suppliers worldwide, which enables them to provide their valuable customers with customised product and service requirements. With a national warehousing and logistical capability, NLA is able to deliver their products quickly and efficiently nationwide. NLA have now launched it’s new merchant division in Johannesburg due to increased demand for smaller quantity requirements from their customers. “Our target market for the merchant division is any size business requiring smaller quantities of timber” says John Teixeira, sales and marketing director for NLA. “We will not offer boards, decking or any other products from the merchant business that will conflict with the operations of our loyal customers”, says John. NLA will use the same strategy in the merchant division that has brought them their success in NLA, that is to exceed their customers’ expectations through exceptional service and sincere relationships.

We live our mission to exceed customer expectations. Our most important value is honesty and integrity. We have built our business on sincere and mutually beneficial relationships. We have a customer centered culture that none of our competitors have been able to copy although many have tried. We are committed to your success. We don’t only sell timber, we offer solutions. We offer value for money. We have a wide range of products.

www.nla-timbers.co.za John Clement Sean Robin Reena

083 603 1774 079 402 4228 083 603 1777 084 717 8624 083 603 1780

Johannesburg / Cape Town Johannesburg (Break-bulk) Johannesburg / Cape Town Port Elizabeth Durban

feature

A solo for solid timber and glass construction House Stöckli, designed by Swiss architect, Pascal Flammer, employs the use of Novatop wooden panels, highlighting the building's simplicity in design. A rectangular ground plan, gabled roof and composite roof covering seem to be nothing unusual, but at a second glance, finer details become apparent. Words and photographs: Katrin Brunner and Barbara Renz

P

ascal Flammer kick-started his now-awarded career by designing a house which bears the name Stöckli. The house, which was built with an entire exterior and interior of wood, was a groundbreaking trend. "The idea simply came into my mind," says Flammer. Stöckli is partly a basement building, but its larger part rests on a bed plate sunk under ground level. The depth was carefully calculated, so that after the process of landscaping, the height of the worktop in the kitchen is level with the built-in furniture along the windows, and the garden.

48

FEBRUARY 2013 //

"The room thus becomes a single space, and thanks to its visual communication with the surroundings, it is also very generous," explains Flammer. Solid Novatop panels bonded together with wooden laths, stacked in a crosswise manner, were used partly as part of the sandwich envelope and partly as the final interior layer – these panels highlight the aesthetic appeal of the wood, which is one of the most distinctive features of this product.

feature

"The room thus becomes a single space, and thanks to its visual communication with the surroundings, it is also very generous," explains Flammer. Flammer incorporated the same material for the cladding of the body of the kitchen units, as well as for the built furniture, doors and shelves. The treatment consists of multiple coatings of natural oil containing white pigment. "In the past, it was done this way," says Flammer. "Oiled wood looks nice and retains its natural appearance. Thus far, there haven’t been any problems."

// FEBRUARY 2013

49

feature

The noticeable fillings of the openings are not, with the exception of the opening parts, connected with any frames, which makes for greater visual space. None of these fillings has more than 8m2 and the length does not exceed 6m, so the handling was also relatively easy. The perpendicular design of the project is disturbed by the two circular window openings located in the gutter walls, against which the sliding door between the two adjoining rooms operates. The spiral staircase which connects all three floors is based on the same shape. "Is it not impractical?� we asked Pascal. “What does practical mean? I think that the extreme regard of 'practicality' has crept into civilization and is the main reason why most of the houses being built are boring, grey, and simply ugly," he concludes. iQ For more information about Novatop, visit www.novatop-system.cz/en/

50

FEBRUARY 2013 //

TCT Precision Saw Blades

Timber Tool

Timber Tool GP

Head Office: Cape Town Tel: +27 21 511 7233 Cell: +27 83 261 6799 Fax: +27 21 511 4004 Email: timbertool@absamail.co.za

Head Office: Gauteng Tel: +27 12 756 4291 Cell: +27 76 353 8017 Fax: +27 86 583 5960 Email: timbertoolgp@gmail.com

BEE Status Level 1

architecture

Rossignol Global Headquarters Photography by: © André Morin, © Christian Rausch, Hérault Arnod

The image of Rossignol, a historic leader in the world of skiing, is intimately linked to the mountains and to snow. The project for its global headquarters has nothing to do with the stereotypical office building, but is a tribute to nature and to the peaks, but also to technology, which is inseparable from top-level sport. 52

FEBRUARY 2013 //

architecture The roof, which envelops the whole project, is topography in osmosis with nature and the landscape. Its organic, timber-clad shape echoes the profile of the mountains that surround the site. In order to create the “House of Rossignol,” the Rossignol Group will be assembling on these sites different entities that are currently spread over several locations, but which all contribute to the company’s identity.

The roof covers three types of space: • The racing ski production workshop, the brand’s technological showcase, and technical rooms, all grouped alongside the motorway. • The office floors, which include the administrative and sales departments, R&D, research and design, etc. • The street, spectacular and bright, the space of social encounter, which crosses the building from side to side. At its end, the street widens to become the showroom.

On the motorway side, the façade creates a kinetic and dynamic effect reinforced by the repetition of the logo, which appears gradually. The front of the building rises to form a roof over the workshops and then on to the apex, and descends again on the south-western side to cover the office area.

T

he plot stands in the middle of a plain surrounded by mountains. It is a stretch of former farmland, marshy and perfectly flat, bounded on the northern side by the Lyon-Grenoble motorway. The architecture has been designed specifically for Rossignol, a fusion of the company’s functional and fantasy aspects, in a surprising and minimalist form: it is inspired by board sports, by fluidity of motion, and also by relief, snow and glaciers sculpted by the elements.

The roof, which envelops the whole project, is topography in osmosis with nature and the landscape. Its organic, timber-clad shape echoes the profile of the mountains that surround the site. // FEBRUARY 2013

53

architecture

Terrace

It is then intercut with patios planted with birch trees that seem to grow through the roof: nature and building intertwine. The irregular profile of the roof and office façades leaves the opportunity for future extensions as required. Additions can be built without disrupting the balance and identity of the project. From the start, the architecture embodies its own growth process. The roof ridge, with a glasshouse running along it, is situated above the street, a high-level space giving onto the “high-altitude restaurant,” the highest point of the structure, which makes reference to ski slope restaurants. Inside, the building functions like a “hive” in which the different functions come into contact and interact, where people enjoy the experience of working together and meeting each other. The originality of the programme is that it assembles very different functions, from production to services, under a single roof. The aim of this assembly is to create a global synergy which eliminates barriers between design, service and technology. Each person in their own diversity – engineer, designer, technician, secretary, salesman, etc. – meets in a reciprocal encounter. To encourage this internal communication, social spaces are distributed around the building.

54

FEBRUARY 2013 //

architecture

Restaurant

The restaurant, situated right at the top and at the gravity centre of the street, is designed as the primary locus for the company life: two great glass roofs divide up the panoramic views to the sky and the mountains, on one side to the Vercors and on the other to the Chartreuse. A large roof terrace is available for alfresco lunching, protected from the noise of the motorway. Whether on the terrace or around a wooden fire, the restaurant turns the midday break into a special moment. Only two materials are used for the external envelope: wood (natural larch) and glass. The structure is made of steel, like an organic skeleton that outlines the shape, with its multiple warped surfaces. The roof frame is visible in the workshop and offices. The post and beam frame of the service floors straddles spans of 12 to 15 metres to leave the space as free as possible. The workshop space has a primary horizontal roof overlaid by the timber over-roof, creating a hidden space between the two, which contains all the technical systems and machinery. This means that no technical elements are visible from the outside; therefore the external shape is pure. The building is designed for minimal environmental impact. The technical choices make it an efficient and energy-saving building, well insulated and protected from the summer sun by the timber over-roof. The systems are optimised – the heat produced by the workshop machines is recovered and re-injected into the heating network. The offices receive natural ventilation through automatic window opening. iQ

// FEBRUARY 2013

55

architecture

Showroom exterior

Datasheet Location entr’alp 2 - La Buisse - Saint Jean de Moirans

Client Skis Rossignol SAS

Project management Hérault Arnod Architectes Project team: Jérôme Moenne-Loccoz (project manager), Alexandre Pachiaudi, Camille Bérar, Nicolas Broussous, Matthias Jäger

Competition team: Florent Bellet, Adela Ciurea, Israel Lopez Vargas, Alexandre Pachiaudi • with François Deslaugiers (for the panoramic lift) • Batiserf - Structure • Nicolas - Fluide • Forgue - Economiste • Cap Paysages - Paysagiste

Restaurant

56

FEBRUARY 2013 //

DESIGNER WOODEN CREATIONS Established in 1996, Africque Designer Wooden Creations specialize in the construction of wooden decks and balustrades. Africque Designer Wooden Creations was part of a team of Landscape Architects whose creative garden designs have been awarded several 1st prizes at the Safari Garden Expo Shows held in Pretoria. We strive and pride ourselves in our craftsmanship and exceptional product quality. Each deck constructed is unique.

MAKE THE MOST OF THE VIEW FROM YOUR GARDEN, HIRE A PROFESSIONAL. • • • •

17 Years experience On-site supervision Dedicated team of professionals Our clients vary from restauranteurs to private home owners and business corporations

AFFORDABLE AND ATTRACTIVE • Enhance your garden, create an entertainment area, or extend your living area with a beautiful wooden deck. • Wooden decks are durable and give an all round feeling of tranquility and space. • Fixed or movable, big or small we will design and construct the ideal deck for your specific needs.

OUR SERVICES INCLUDE THE FOLLOWING: • • • •

Wooden Decks Balustrades Wooden flooring Pergolas

SOME OF OUR PRODUCTS USED CONSIST OF THE FOLLOWING: DECKING • • • •

CONTACT DETAILS VAN HUYSSTEEN MEYER 079 551 0135 078 103 7057 vh@africquewoodendecks.co.za www.africquewoodendecks.co.za

Massaranduba Red Ironwood Sugargum Colorado

FLOORING • Teak • Rosewood • Saligna

architecture

Datasheet Assistants to the contracting authority • Cotéba • Génie des lieux - Space planning

Surface area 11 600 m² net floorspace

Timetable • Competition: 2006 • Work beginning: spring 2007 • Delivery: June 2009

Programme • Offices and open spaces for administrative departments, R&D, design, etc. • Racing skis workshop • Showrooms

Images Labtop-rendering, Hérault Arnod

Photos © André Morin, © Christian Rausch, Hérault Arnod

Model Atelier FAU (photos © André Morin)

www.herault-arnod.fr

58

FEBRUARY 2013 //

Timber & Composite Decking Installers

www.timbermann.co.za Land: +27128110237

| Cell: +27837995353 | office@timbermann.co.za

dÉcor

The South meets the city Manhattan meets the Southern Way in the design of Southern Eleven, a new Southern style BBQ house in Spinningfields, Manchester. Design objective: To design and build a restaurant that is authentically Southern States of America, but with a modern, trendy, and urban twist. Based on a brand positioning of an authentic Southern style BBQ house for diners today, a sophisticated casual dining eatery was established to illustrate the concept of ‘Southern Way meets Manhattan.’

Challenges: Based on an American concept, finding the right partners in the United Kingdom to execute the concept of the restaurant was a challenge - so too was project-managing the build from South Africa. Ensuring that the original vision for the restaurant was met and delivered with the right execution and detail required constant input and attention.

60

FEBRUARY 2013 //

dÉcor Inspiration: Tassels/fringes (cowboys, Indians and modern fashion). final product: Tassel influence in lighting and wall art (photography).

Inspiration: Totem poles. final product: Carved pole wall separating restaurant from kitchen.

// FEBRUARY 2013

61

dÉcor Inspiration: Chopped wood/wood textures. final product: Natural wood lamps and communal table.

Inspiration: Saloon furniture. final product: Saloon-inspired bar and table legs.

62

FEBRUARY 2013 //

We manufacture outdoor patio furniture, sun loungers, bar stools, Morris sets, trolley servers, etc.

African

- Teak - Rosewood - Kiaat - Saligna

Tel: (011) 969 6174 Cell: 073 109 7793/078 158 1936 Email: naturalliving26@gmail.com Web: www.timberpolemarket.co.za ADDRESS: 136 Springs Road, Benoni, Johannesburg

TIMBER & POLES 4 AFRICA Best prices on poles and other timber products 18 years’ experience

Products:

TEL: (011) 969 6174 EMAIL ADDRESS: timberafrica@mweb.co.za WEBSITE: www.timberpolemarket.co.za ADDRESS: 136 Springs Road, Benoni, Johannesburg

• CCA treated poles • CCA droppers • CCA & U/treated pine • CCA garden edging • Split poles/trimslabs • Meranti balustrading, windows, skirting & doors • Jungle gyms, dog kennels, wooden offices • Picket fencing • Timber decking – Teak, Saligna & Pine • Log profiles – Pine

We will beat any written quote

SANS APPROVED SATAS

dÉcor Inspiration: Communal table. final product: Communal table.

The result: City Life’s ‘Definitive Guide to What’s On’ in Manchester gave Southern Eleven an overall rating of 4/5: 5/5 for décor, 3/5 for service and 4/5 for the food. The reviewer states “S11 has not skimped on the interior, and I like it… it balances nicely between stylish and cowboy.” The restaurant is busy and the client is looking to roll out one or two more stores in the region for others to enjoy hospitality the Southern way. iQ

64

FEBRUARY 2013 //

Supplier of timber log wall systems, solid and half logs, decking, laminated posts, poles, pickets and timber balustrades.

Solid Log

T&G Half Logs

Contact details: Head Office & Factory Physical: 8 Fechter Street Knysna Industria Postal: PO Box 2385 Knysna, 6570

Pretoria: Cell: Kobus 082 535 3397

Cell Francois: 082 411 0513 Cell Brett: 082 553 2822 Email: timbaclad@telkomsa.net Fax: 044 382 6358 Web: www.timbaclad.com

research

Timber homes in South Africa Past, present & future

This is an excerpt from a presentation delivered by Jacques Cronje at the HWZ International Third Wood Conference, 8 Feb 2013, CTICC, Cape Town. Statistics Despite statistics such as that 70% of the developed world’s population live in timber frame homes, and despite the resurgence in the popularity of timber homes in Europe in the last decade, my question is whether or not timber homes in South Africa will maintain such a relatively miniscule share of the local market. According to the 2011 Census, homes of a current value of R1m and upwards, which are not ‘bricks or cement block/ concrete’ account for less than 0.38% of the total, with the figure for new houses built from 2000 to 2010 at just over 0.5%

Timber homes in South Africa a brief history The predecessors of the timber home in South Africa are the wood frame and iron clad homes, some imported in kit form from Europe, and others designed and built here from the late 1800s to the early 1900s. The most well known of these is the Smuts House, prefabricated in the UK, shipped to India, and later brought to South Africa where it was re-erected at Doornkloof for Jan Smuts in 1909. An example of an iron clad timber frame building designed and built locally, is the Globe Tavern in Barberton, which opened for business in 1887 and was designed by Arthur Hubert Halder. Another example is the Millwood House, now a museum in Knysna. The house was originally built in Millwood during the ‘Gold Rush’ in 1885, and was later relocated in sections

66

FEBRUARY 2013 //

to Knysna by ox-wagon, and re-constructed where St. George’s Church Hall now stands. It was moved to its present site in 1910. An example of a remaining timber clad building from that era is the Woodcutter’s Cottage, built in the 1880s, on display at the George Museum. After this era of timber frame building, iron clad timber frame buildings fell out of favour with the local authorities, and a period followed when they were all but completely outlawed. Many of our older title deeds still contain clauses such as ‘no corrugated iron.’ Up to the 1950s, the few timber buildings that were built were still being built of hardwoods. It was only around that time, with the introduction of preservative treatments that softwoods, such as Pine, started gaining in popularity as a construction material, and it was in the 1960s that timber buildings were re-introduced as an alternative to brick and mortar. Among the pioneers of this re-introduction of timber homes were Searles Homes in Great Brak River, who initially built timber frame homes to house the staff for their shoe factory. Others were Elgin Homes in Grabouw, and NST in Knysna, who introduced solid wood and log cabin building systems. While it is evident that much of the design was based on function, an exception to this was the magnificent Bruynzeel House in Stellenbosch, with its hyperbolic paraboloid roof, designed in 1960 by Aart Bijl and built by Kees Bruynzeel, a Dutch wood merchant. The majority of timber homes at the time, however, were relatively inexpensive holiday homes built along the southern cape coast, many of which were prefabricated.

In 1982, some members of the timber building industry got together to form the Timber Frame Builders Association, now called the Institute for Timber Frame Builders, which went a long way in achieving the recognition the quality timber buildings enjoy today, particularly with regards local authorities and lending institutions. If we look at a graph from the 2011 Census data showing the percentage of ‘non-brick & cement block’ houses since 1960, we see that beyond the spike in the 1960s (from close to zero % before that), little if no growth in percentage up until now. This is while the percentage of timber buildings continues to increase year after year in many parts of the world, as people become more aware of the benefits of available systems. It is my guess that the perception of timber homes as a cheaper and less desirable alternative, perhaps still a result of its humble iron clad origins and later cost– effective prefab holiday houses, still persists among many.

Ingco tools are used in the industry, in const construction, woodworking, metalworking,

Why timber homes? What is the fuss all about? Should we not just continue doing things here as we always have, building most buildings out of bricks and mortar? What are the benefits?

and around the house by artisans that

For the client: 1. Insulation – and therefore energy costs. Perhaps not yet such a huge issue, but with a potential electricity hike of around 16% for the next 5 years at this stage, it soon will be. 2. Natural home – Many clients choose to build a timber home because they want a more natural home that better fits into its environment. The same applies to beach resorts, and lodges in nature reserves. 3. Ease of construction and time to construct – It takes significantly less time to build a timber home than a similar brick and mortar home. It’s also easier to alter or add on to it at a later stage – and a lot less messy. 4. Difficult and sensitive sites – Due to using relatively lightweight materials, several of my projects have been on difficult-to-access sites, where getting timber there is pretty easy compared to bricks. For sensitive sites, timber construction also allows one to nestle right in between the existing vegetation with minimum disturbance. There are also cost savings on steep sites, by using suspended floor structures.

// FEBRUARY 2013

67

enjoy the reliability and affordability of these tools. Ingco gives you a one-year warranty on power tools.

research

Percentage of non 'brick & cement block' main dwelling houses valued currently at R 1m or more, built from 1941 onwards Data from 2011 Census.

For the environment: 1. Less energy used = less emissions – Until such time as our energy is produced from renewable resources, and not coal, any savings in energy are savings in harmful emissions. 2. Low embodied energy – Of the various readily available raw materials for building, timber has, by far, the lowest embodied energy, and if grown in a sustainably managed plantation, is a truly renewable building resource. In terms of strength to weight, radiata pine, for example, has a strength-to-weight ratio 20% higher than structural steel, and more than four times that of unreinforced concrete in compression. 3. Carbon sequestration – Trees absorb carbon as they grow and this carbon is locked away when the timber is used for construction – so the more timber used instead of more energy- and carbon-costly materials, such as masonry and concrete, the lower the carbon footprint of your home. 4. Treatment – Most preservative treatments, which while providing the benefit prolonging the lifespan of timber indefinitely, have not been considered ideal from an environmental perspective. This is changing with the introduction of new preservative treatments such as Tan E, which was recently accepted by Ecospecifier global.

For the architect/designer: 1. Contemporary – Driven by technology, everything around us is advancing in leaps and bounds. Timber, along with other new lightweight building systems, allows us to be part of that technological revolution, rather than building the way we were in the pre-digital age. Technological advances in design software and digital fabrication technologies are now too allowing timber to be cut and fashioned to any shape or form.

68

FEBRUARY 2013 //

2. Versatility – Thanks to the extreme versatility of timber, your timber home could be anything from a humble log cabin, to a grand Cape Cod style beach house, a sleek glazed all round clad post and beam house, or a digitally crafted open-plan contemporary house with a freeform double curved roof. 3. Building Regulations – Timber homes are included in the South African National Building Regulations standards, in SANS 10082, Timber Buildings. When built to these standards they also automatically achieve the standard required for registration with the National Home Builder Registration Council (NHBRC). They are also easily designed to meet the requirements of the new Energy Efficiency regulations SANS 10400 Part XA .

For the builder: 1. Passion – Speak to any specialist timber builder and you are likely to find someone with a passion for their craft and for working with wood. Who would you rather have building your house? 2. Precision and neatness – Building with timber is a precise form of construction. Everything needs to be just right to work. For a builder and all involved it’s easier to monitor and see that everything is working according to plan.

Timber Building Poll held in conjunction with Timber iQ Given the clear advantages and consistently small uptake, I recently set up a poll, along with Timber iQ magazine, to help determine attitudes towards timber homes in South Africa.

We had just short of 120 respondents, of which 29% were in the design or architecture field. What was most interesting was that 38% of the respondents had previously or currently live in a timber home – and clearly wanted to share the advantages. Although I had not anticipated that such a large percentage of respondents would have lived in timber homes, their responses were of the most interest, particularly because, in each of the following cases, their responses, on average, rated higher than those who had not lived in a timber home. When asked to rate timber homes compared to brick, where an answer of 1 is much less, and 5 far superior, in favour of timber, the average scores were as follows: {The first figures for each are for people who have lived (or still do) in timber homes, and the figures in brackets are the averages for all respondents.} • • • •

Energy efficiency Time taken to build Maintenance requirements Risk of fire

3.93 4.60 2.87 2.60

(3.80) (4.41) (2.70) (2.35)

So, while at best the results could be said to be biased, as it was mostly people who like or have lived in timber homes and who took time to do the survey, what I found relevant is that the comments by people who have lived in them showed that timber homes, even amongst this sample group, perform and are generally better than general perception.

saving electricity saving money saving nature

Eco-friendly solution for energy-efficient buildings