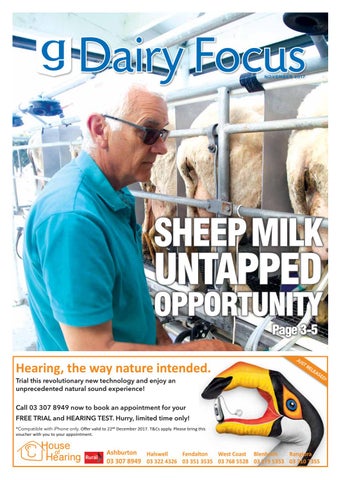

Dairy Focus NOVEMBER 2017

SHEEP MILK

UNTAPPED

OPPORTUNITY Page 3-5

Hearing, the way nature intended. Trial this revolutionary new technology and enjoy an unprecedented natural sound experience!

JU

ST R

EL

EA

SE

Call 03 307 8949 now to book an appointment for your FREE TRIAL and HEARING TEST. Hurry, limited time only! *Compatible with iPhone only. Offer valid to 22nd December 2017. T&Cs apply. Please bring this voucher with you to your appointment.

House of Hearing

Ashburton Halswell Fendalton West Coast Blenheim Rangiora 03 307 8949 03 322 4326 03 351 3535 03 768 5528 03 579 5353 03 310 7355

D!

Dairy Focus

2

www.guardianonline.co.nz

Dairy Focus Dairy Focus is proudly published by the Ashburton Guardian Limited

Enjoy reading Dairy Focus? You may also enjoy Guardian Farming

Colin Williscroft

Read the latest Guardian Farming online at guardianonline.co.nz We appreciate your feedback. Editorial Email your comments to colin.w@theguardian.co.nz or phone 03 307 7956. Advertising For advertising enquiries email penny.s@theguardian.co.nz or phone 03 307 7973. Post Ashburton Guardian, PO Box 77, Ashburton 7740.

Milking

EDITORIAL COMMENT

RURAL REPORTER

The warmer weather that’s now with us signals the start of the irrigation in many parts of the South Island and from what I’ve seen from the car recently, irrigators are operating throughout parts of Canterbury. At the time of writing another part of the region was set to be hooked up to a reliable water supply, with the Sheffield Irrigation Scheme, part of the Central Plains Water Network due to come on-stream last week. While that will bring smiles to many farmers in that area, the news that the anti-irrigation brigade has not let up, will not. A few days ago Greenpeace delivered a petition to Parliament calling for an end to government funding of irrigation schemes. Fortunately IrrigationNZ was quick to jump on that piece of misinformation, pointing out that any money that went towards schemes came in the form of a loan that has to

be paid back – with interest. It was a timely reminder that farmers need to get on the front foot to tell their stories because, while that may not have been what was done in the past, there’s plenty of people quite happy to have a pot shot or two from the sidelines and if those comments are left unanswered, it doesn’t take long before they are viewed as facts – especially when it comes to things like the environment. Milking sheep hit the news during the past couple of weeks due to a research paper out of Lincoln that pointed out their environmental impact was much less than that of cows and that if we really were interested in clean and green then sheep could provide an answer. No one here is suggesting that dairy sheep will ever assume the importance of cows in New Zealand but this month’s issue of Dairy Focus takes a look at milking sheep, who they might appeal to and what sort of future there could be in it. I’m not expecting too many farmers with dairy cows would ever consider milking sheep but whether it’s a niche industry with potential to grow into Asian markets if a biggish player came along and pumped some money into it further down the track is something worth considering.

INSIDE

PAGE 6-7

BREEDING FOR NITROGEN REDUCTION

PAGE 8-9

WORLD DAIRY SUMMIT DISCUSSIONS

PAGE 22-23

ADVANTAGES OF EFFICIENT IRRIGATION

BARRY WHITTAKER CONTRACTING LTD.

PAGE 27

VOLATILITY PROMPTS STRUCTURE CHANGE

Innovative Instigator

THE MAINTENANCE MASTER Removing the build up on the edge of Dairy Lanes, allowing stock to move easier, faster & lanes no longer contribute to health & feet issues. Fill can be used for: • Around water troughs • Farm track & driveway ruts • Filling trenches • Erosion around irrigation ponds

RUT MASTER | INSTIGATOR P: 03 302 3888 M: 0274 803 380 E: b.jwhittaker@xtra.co.nz

Digger also available

www.guardianonline.co.nz

3

sheep a viable alternative

Sheep heading up the ramp to the milking plant. PHOTO BY COLIN WILLISCROFT

New Lincoln research has suggested that dairy sheep are a better prospect than cows to fulfilling the green credentials New Zealand uses to differentiate its produce in the global market. However, is that likely to become a reality? Will dairy sheep ever challenge dairy cows as an industry in New Zealand? Senior lecturer in agribusiness management at Lincoln Dr Nic Lees co-authored the paper “Competitive advantage through responsible innovation in the New Zealand sheep dairy industry”. It found, rather than competing on cost, the sheep dairy industry should promote sustainability and environmental benefits, and be innovative. “Future environmental constraints make milking sheep a more sustainable option than milking cows in New Zealand,” Lees said, pointing to the fact that sheep do not have the same nitrogen leaching effect as cows because they have a lower volume of

Colin Williscroft

RURAL REPORTER

urine. Sheep milk also had health benefits, Lees said. It has three-times higher whey content compared to cow milk, which aids digestion. It also has higher calcium and higher vitamin D levels, which aid the regulation of phosphorous and calcium absorption essential for bone mineralisation. He said sheep milk also contains different forms of proteins that are unlike the beta-lactoglobulin and alpha S1 casein in cow milk that commonly cause milk allergies and intolerance. There is an opportunity to build on the positive perception of low intensity, pasture-based production systems, Lees said. “By emphasising these

attributes in marketing, sheep dairy products could obtain market advantage and could potentially gain higher product premiums. At the same time, this would help meet the requirement from stakeholders for environmentally sustainable agricultural production. “Furthermore, consumers are increasingly looking for foods that align with their personal values, such as environmental sustainability, animal welfare, fair trade and organic production. The industry has the potential to see this not as a compliance cost but as a way to provide a valuable competitive advantage.” He said it could invest in developing new innovations such as superior sheep milk products for niche sectors like health, infant care and gourmet food. It has a much creamier flavour than cows’ milk, due to its higher fat content. It is estimated that the demand for sheep milk is growing by 10 to 20 per cent each year and New Zealand’s

largest sheep dairy operation, Blue River Dairy in Southland, has seen a 50 per cent increase in the milk powder price over the past three years. Since that paper was published Lees said there had been some interest in its findings from the media in New Zealand and Australia, probably because the environment is such a hot topic, but little or nothing from the dairy industry itself, which did not surprise him. “People are intrigued by the idea of sheep milk but most people in New Zealand know very little about it and probably think it is very similar to goat’s milk, which it isn’t really. “That’s not the case worldwide, in places like Greece it’s quite common to drink milk from sheep.” Lees would be surprised if any dairy cow farmers in New Zealand would ever consider change to milking sheep. “It’s more likely to be sheep and beef farmers looking for higher value. Continued on next page

MANUFACTURERS OF TIMBER BOXES & PALLETS So for all your pallet or box requirements, no matter how big or small, give Wayne a call today at Adams Sawmilling Also Manufacturers/Suppliers of FARM IMPLEMENT SHEDS IRRIGATION PUMP SHEDS • Concrete Water/Feed Troughs • Precast Panels • Silage Pits • Water Tanks/ Effluent Tanks • Concrete Bunkers • Weeping Walls • Killing Sheds • Cattle Stops

Adams Sawmilling Co Ltd ISPM 15 accredited for Export Pallets

Malcolm McDowell Drive, Ashburton Ph (03) 308 3595 Fax (03) 308 5649

WE GO THE EXTRA MILE Waste and recycling collection services for rural New Zealand. • The easy and safe way to dispose of your general waste and co-mingled recycling • Our range of front load bins are strong and robust, ideal for farm use • Schedules and bin sizes can be tailored to meet your specific requirements

To order your front load bin, give us a call on 0800 240 120. Conditions may apply.

4

Dairy Focus

from p3 “It’s a culture thing. Very few sheep and beef farmers would convert to dairying because they don’t want to milk cows and most dairy farmers won’t want to milk sheep. “Sheep are quite a different animal.” With irrigation schemes bringing a reliable, on-tap water supply to South Island paddocks that have not had that luxury before, there are new opportunities for dairy sheep numbers to grow, Lees said, adding that if land uses in those areas are to justify the cost of accessing that water, farmers will need a high value product to justify that cost. “Sheep milk will provide a viable alternative. “It will give sheep and beef farmers an alternative source of income. It stacks up pretty well financially.” Earlier this year dairy sheep numbers in New Zealand were estimated at just over 30,000, milking for around 16 producers, according to figures released by AgResearch. Lees said that, given time, that number could rise to around the million mark. He said one of the advantages dairy sheep have over cows is the price paid for

www.guardianonline.co.nz

sheep milk. At around $2 a litre it can be viewed as a high value product, although that’s offset by volume, as production from sheep is much less than cows. Although the jury is out on just how much of a market there is in New Zealand for sheep milk, the potential for exports cannot be ignored. For people in Asia, sheep milk is a known commodity and one that is embraced for a variety of reasons, Lees said, and there is significant potential in the market there for infant formula. Sheep milk is more closely aligned in its profile to human breast milk, he said, while people who have intolerances to cow’s milk are more likely to tolerate sheep milk. However, as with any small or developing industry, it’s going to take someone to throw a bit of money at it to take it to the next stage. “From where I see the market, it’s going to require a number of large operators to set up a sheep milk powder plant to enable the increased production of sheep milk infant formula for export. “One of the challenges we face in Canterbury is that we don’t have a sheep milk processor, so people are reluctant to expand into sheep dairy.

“No one has invested in a milk powder drier. We’re caught between a rock and a hard place because potential investors don’t want to invest that sort of money until they see a secure supply.” He said for the industry to go to the next level it needs someone with relatively big pockets to believe in the export market and to put their money behind it Darfield dairy sheep farmers Guy and Sue Trafford only

began milking sheep in Canterbury relatively recently, but they knew of their potential much earlier, having come across them when they were managing a large Maori trust farming operation near Gisborne around 2001. That was about the time respected animal geneticist and former AgResearch director Jock Allison got behind the east Friesian milking breed and the Traffords’ employers at the ‘time decided to give the breed

IRRIGATION & DOMESTIC WATER WELLS

LOCALLY OWNED & OPERATED • Latest Well Drilling Equipment • Licensed owner operators • Generator for hire service

Considering Selling? Call Mike who has proven rural expertise and the marketing reach to achieve the best result for your property. 34 High Street, Geraldine Freephone 0508 227 237 Phone (03) 693 1403 Wayne 027 221 1467

WELL VU CAMERA CAN VIEW DOWN TO 300M

Mike Preston M 027 430 7041 | B 03 307 2400 mike.preston@bayleys.co.nz | mikepreston.co.nz WHALAN AND PARTNERS LTD, BAYLEYS, LICENSED UNDER THE REA ACT 2008

www.barberdrilling.com

a go. It was an experiment that didn’t work out for a number of reasons - but it did trigger an interest. “We could just see what amazing sheep they were,” Sue said. Today many of the problems they encountered from those early days are gone, with cross-breeding and better management making east Friesians a far better option in New Zealand conditions. So when, after deciding to

www.guardianonline.co.nz

5

Far left - Morning milking with, from left, Sue and Guy Trafford (obscured) and farm worker Sarah Morgan.

Middle - Food keeps the sheep occupied during milking.

Left - Lincoln University lecturer Nic Lees says future environmental constraints make milking sheep a more sustainable option than milking cows.

PHOTOS BY COLIN WILLISCROFT

get out of Christchurch and moving to the Darfield area following the 2010 earthquake, the Lincoln University lecturers decided to take up the challenge of dairy sheep. After initially buying about nine hectares they now have access to just under 40, thanks to leases and friendly neighbours. They run about 200 ewes, mainly east Friesians crossed with awassi, a breed that originated in the Middle East.

The ewes are milked once a day for about 200 days a year. It’s been anything but easy going since they started, and the couple are glad they didn’t give up their day jobs but maybe, just maybe, there’s light at the end of a long and sometimes narrowing tunnel. When they made the move into dairy sheep it wasn’t about becoming pastoral farmers, Sue said. It was more about creating a food business and with any

luck there was the possibility of doing the hard yards for a possible future Canterbury niche industry. “It’s a bit of a research project as well as a commercial business.” The initial plan was to provide milk for ice cream and early on it seemed Deep South Ice Cream were on-board. However, for one reason or another that deal failed to materialise so the Traffords were left scrambling for

contracts to sell their milk. Fortunately, a local cheesemaker came to the party, which helped get them through to the next challenge. Compliance. “The biggest horror we’ve had to face is compliance,” Guy said. “It just seems so random. The people at MPI (Ministry for Primary Industries) are great but the system itself is a different story.” As there are not too many involved with dairy sheep in Canterbury, getting up and running has involved a bit of trial and error, Guy said. “We’ve learnt a few things on the way.” They bought their milking plant from a former goat farmer, while their pasteuriser was imported from Greece. To have a bit more control over the business from pasture to bottle (or plate, as ice cream is still on the menu, down the track), they are now setting up their own milk processing plant, which, when it’s up and running, will mean the Traffords will be able to take milk from other farmers in the area with dairy sheep. However, like their Lincoln colleague Lees, they realise that for the industry overall to go to the next level a major player will need to come in.

Guy said it would cost around $55 million to build a new milk drier for Canterbury, and no one is going to do that until they have a security of supply to pay for it. Blue River Dairy’s drier in Southland is too far away, although the Invercargill company is showing the industry the future in other ways. Initially Blue River only produced sheep milk feta cheese but today it’s expanded into more cheeses, ice cream and milk powder. It has evolved into an export-focused infant nutrition business and only last month it achieved registration with the China Food and Drug Administration to register its brands of infant formula there, something that will be required to export into China from the beginning of next year. It was an important achievement and one the company is rightly proud of. However, for the rest of the industry there is still much to achieve. There is, it seems, plenty of room to expand, if it can attract more investment. However, even if that occurs, it will likely remain a niche industry to some extent, with the cows still holding sway.

Charlies Takeaways Charlies Takeaways rAKAIA

A Division of Robsons Canterbury A Division of Robsons Canterbury

LIQUID WASTE MANAGEMENT

SEPTIC TANKSEPTIC EMPTYING MAINTAINING, PUMPS SUPPLIED AND FITTED, GREASE TRAPS CLEANED TANKAND EMPTYING AND MAINTAINING, PUMPS SUPPLIED AND FITTED

aways

LIQUID WASTE MANAGEMENT

intaining, pumps supplied and fitted

ALL ANIMAL EFFLUENT EMPTIED AND SPREAD - IF ThE POO IS WET OR DRY, WE’LL REMOvE AND MAKE FLY MuckIT spreader,

20,000 LITRE TRACTOR DRAWN TANKER

14 Vacuum Trucks Water Tankers Water Jetters 20,000 Litre Tractordrawn Tanker Dry Muck Spreaders Front End Loader Port-a-loos

a new addition to our fleet

DRY MUCK SPREADER

POTABLE WATER DELIVERIES • PORT-A-LOO HIRE ANDEMPTIED SERVICING • WATER JETTER WITH DRAIN CAMERA ALL ANIMAL EFFLUENT AND SPREAD Rakaia 0800 372 004 Contact us for free advice and quotationsVisit our website for Rakaia: 0800 372003 004 Christchurch: 372 003 more0800 information Christchurch 0800 372 Email: robsonenviro@xtra.co.nz Website:www.robsonenvironmental.co.nz www.robsonenvironmental.co.nz robsonenviro@xtra.co.nz

031715C1955

100% Canterbury family owned operated | Inin the business years 100% Canterbury family ownedand & operated • Been thewaste business for overfor 4040 years

6

Dairy Focus

www.guardianonline.co.nz

Genetic solution to nitrogen

Leeston farmer John Tanner has turned to genetics as a way of reducing the nitrogen PHOTO SUPPLIED footprint on his farm.

NICK’S PETFOOD LIMITED “We’ve been in the industry for the past 15 years.”

Nick’s Pet Food Ltd buy unwanted animals • Cattle • Goats • Calves • Horses • Other farm animals Please call Nick for more information 027 210 1621/03 348 9439 or send us an email nick.pacey@hotmail.com

Canterbury dairy farmer John Tanner has been working hard to improve sustainability on his Leeston farm, Dunlac Dairies Ltd. The farm is located in the Selwyn Waihora catchment and is just 20 kilometres from Lake Ellesmere (Te Waihora), which is considered one of New Zealand’s most important wetland areas. On either side of the catchment are the Rakaia River and the Selwyn River. “In Canterbury we have to lessen our nitrogen footprint on the farm,” said Tanner, who milks 730 dairy cows during the peak of the season on 260 hectares. “In our catchment, we farm on environmentally sensitive land.” Tanner is one of many farmers turning to genetic solutions to help him farm well. In recent years Lake Ellesmere has been plagued by water quality issues related to intensive farming practices. Nitrogen leached from farms on the Canterbury Plains will eventually make its way into Lake Ellesmere, therefore farm

www.guardianonline.co.nz

7

reduction

Their favourite feed is also New Zealand’s

favourite.

*

ECan councillor and farmer John Sunckell understands the importance of PHOTO: ASHBURTON GUARDIAN meeting environmental targets.

activities in the catchment are carefully regulated by Environment Canterbury, with set nitrogen limits per farm. The Selwyn Waihora Water Plan, a section of the Canterbury Land & Water Regional Plan, includes policies, rules, and limits to manage water quality and water quantity in the Te Waihora/Lake Ellesmere catchment, with particular emphasis on the longterm health of Te Waihora. Among other things the strategy requires dairy farms in the catchment to reduce their property’s nitrogen limits by 30 per cent by 2022. Tanner is making an effort to reduce Dunlac Dairies’ environmental impact, and has made significant improvements with water management and fertiliser usage. The farm was a finalist in the Dairy Business of the Year 2016, and Tanner takes pride in doing his bit for the environment. However, like many farmers in the region, he is feeling the pressure. “We are trying to milk at our current numbers, but lessen our nitrogen footprint. So you are trying to do the same, but with less environmental impact,” Tanner said. He believes that science will offer a solution for farmers. When he heard about CRV Ambreed’s genetic discovery, and its LowN Sires bull team, Tanner was very interested, purchasing more than 200 straws. In March, CRV Ambreed announced a genetic discovery, thought to be a world-first, which could reduce nitrogen leaching on New Zealand farms by 20 per cent within 20 years. CRV Ambreed identified and selected bulls genetically superior for a new trait related to the amount of urea nitrogen in milk. Farmers are now able to breed cows using straws of semen from CRV Ambreed’s LowN Sires, and those daughters will have reduced concentration of Milk Urea Nitrogen (MUN). Cows bred for lower levels of MUN are expected to excrete less nitrogen in their urine which will, in turn, reduce the amount of nitrogen leached from

grazed pasture. This could potentially save New Zealand 10 million kilograms in nitrogen leaching a year, based on the national herd number of 6.5 million dairy cattle. “When CRV Ambreed came up with their LowN bulls, we thought ‘we’ll have a go’,” Tanner said. “We have 730 cows and if we can lessen the nitrogen from the herd by 20 per cent, then that makes a big dent.” Tanner is interested to see how his herd’s genetics will improve over time. “I know it’s going to take a few years, but if it’s something that does improve nitrogen leaching from my cows, I will probably buy more straws in the future,” he says. Tanner was also pleased with the other traits. “We wanted the best in genetics, and CRV offered that,” Tanner said. “To also have the option to reduce nitrogen leaching is an added bonus.” Canterbury regional councillor John Sunckell is also a big fan of CRV Ambreed’s LowN Sires programme. Sunckell is a third-generation farmer from Leeston, in the Selwyn/Waihora zone. He understands the pressure on farmers in the area, and said most farmers “are aware of what’s required and that change is happening”, and understand the importance of reducing their environmental footprint. “Technology and information is vital; that’s why I’m so excited about (CRV Ambreed R&D scientist) Phil Beatson’s work and CRV’s work,” Sunckell said. “It will enable us to still farm and meet environmental regulations.” Sunckell said dairy farmers in his catchment are required to reduce their nitrogen loss by 30 per cent “which equates to getting rid of every third cow”. “However, if LowN Sires can have an impact by reducing nitrogen by up to 20 per cent, and with other new scientific developments (like Agricom’s Ecotain plantain) we are able to reduce nitrogen in the cow’s urine patch, then – all of a sudden – with these two bits of science, we are getting there.” DJ6743_SW_calf_campaign_ad_360x124_v5.indd 1

24/07/17 12:36 PM

8

Dairy Focus

www.guardianonline.co.nz

Focus should be what happens At times we can get wrapped up in what we in New Zealand regard as important and think that surely our customers will also think it is important. But sometimes the big wide world doesn’t think it’s that big a deal. Likewise, there are issues that we don’t think rate but the rest of the world does.I recently had the privilege of attending the International Dairy Federations’ World Dairy Summit in Belfast. I went to the conference sessions on animal welfare, farm management and sustainability and also attended the various business meetings on those subjects. In the environment space, climate change again stood out as the global focus. Food waste was also covered and biodiversity got a bit of mention. But not a lot of talk on water quality - if any at all to be honest. On climate change New Zealand is the only country focused either on including biological emissions in an ETS or having a carbon charge on them. The focus

Andrew Hoggard

FROM THE FEDS

of other countries is actual reductions. Many have set reductions goals, generally on an intensity basis (meaning carbon equivalent per litre of milk) but some were looking at total reductions. In that instance it seemed no country had a solution for how that could be done beyond a reduction in production, and no one sees that as a viable option. Where countries hadn’t set reductions targets often milk companies have, so despite President Trump pulling out of the Paris Agreement, the US dairy industry has set itself a goal. Often the companies or countries provide their farmers with online calculation tools. But in

New Zealand is the only country focused either on including biological emissions in an ETS or having a carbon charge on them.

another bit of difference with New Zealand, data input for these tools is relatively simple and can be done by the farmer, and the focus isn’t about being overly exact, it’s about getting movement in the right direction. Compare that to New

Zealand and good old Overseer and the need for farmers to spend thousands on accredited consultants just to enter data. Once again New Zealand feels it has to be the only virgin in the brothel. Quite frankly this is something we should be

copying from overseas. As a farmer I have little understanding of what a change in one area will mean for my farm’s carbon footprint. You might make changes you think are good, but in reality the effect is negligible. By and large the data New

YOUR HOME OF ORIGIN AGROUP

Visit our website for more on how the POTTINGER

ALPEGO

GASCON

JOSKIN

Disc Mowers / Tedders Rakes / Loader Wagons Power Harrows Seed Drills / Cultivators Ploughs / Disc Harrows

Power Harrows / Rotary Hoes / Sub Soilers Mulchers

Disc Harrows / Chisel Cultivators

Slurry Tankers / Muck Spreaders / Trailers Meadow Aerators Pasture Toppers / Cargo Systems

BOGBALLE

HATZENBICHLER

DALBO

MANIP

Fertiliser Spreaders

Air Seeders / Tine Harrows

Cambridge Rollers

Front End Loaders Tractor Weights

0800 432 633 www.dne.co.nz ASHBURTON | BLENHEIM | CHRISTCHURCH | GREYMOUTH KAIKOURA | NELSON | OAMARU | TIMARU

www.guardianonline.co.nz

9

on-farm

STEEL BUILDINGS with FACTOR Sheds Shelters Commercial Rural

100% New Zealand! Designed/Engineered/Owned.

Trustworthy NZ Suppliers! Reputable, reliable & long-established.

Good People doing Good Business! If global food waste was a country it would be the third largest greenhouse gas emitter after China and the USA.

Zealand farmers are already providing to dairy companies for calculating nitrogen losses are the same pieces of data required for calculating greenhouse gasses. That’s ridiculous we need some synergies here. Another big discussion point at the conference was the increasing overlap between sustainability and nutrition, particularly in relation to all the alternative plant-based dairy products out there. A selling point of the plant-based alternatives is that they’re often pitched as having a lower carbon footprint. But in reality, when you look at the actual nutrition you get from them, then to get the same amount as you would from a serving of dairy, you have to consume a lot more. There are a number of studies now where it has been shown that the carbon footprint is actually higher for the alternative when you take into account the need to get the same level of nutrition. Reducing food waste also came up. It’s estimated one third of the world’s food is never consumed, be it at the farm where it fails to meet quality standards for sale, in the supply chain due to inefficiencies, or most commonly in the consumer’s fridge. Why is it an issue? We have an

increasing world population that needs food, a reduced area to produce food on, and a focus on climate change. Cutting wastage could make a big difference. The good news for animal-based proteins is that they often aren’t the ones thrown out of the fridge for turning into a science experiment. I guess the take home message for me is that it doesn’t matter whether you accept the scientific consensus on climate change or not, or argue about whether some of the experts are truly that expert. It’s irrelevant because the people who buy our products accept this viewpoint. So while we have a good story to tell around the carbon footprint of our produce on a per unit basis compared to our competitors those competitors are trying to catch up to us, and they are coming up with good stories to make it sound like they are doing better. If we want our customers to keep buying our products we need to show them that we are serious about addressing any concerns they have. A key point our politicians need to remember: those customers don’t care about what pieces of legislation you write, they care about the actual things that happen on our farms.

Get the best solution for your building project.

Premium, Quality Product! We use only the best materials.

Bigger, Stronger Buildings! with no knee or apex braces!

BRANZ Appraised! New Zealands 1st & Only.

Contact your local X Span Agent

Dave McLeod Snowfed Builders 0274 342 857 FROM CONCEPT TO COMPLETION - THE X SPAN EXPERIENCE IS BEST!

• It’s not just your livestock that need to be in good condition • Banish the aches, itching or restless legs associated with your varicose veins • Treatment options include injections, laser or minimally invasive surgery

www.xspan.co.nz

10

Dairy Focus

www.guardianonline.co.nz

ENERGY FEATURE

Survive summer with these tips Meridian Energy want to make sure you’re getting the most out of your electricity and have pulled together a few tips for the farm. Electricity accounts for around 11 per cent1 of your dairy farm operational expenses. Whilst as a percentage it doesn’t seem a lot in the big scheme of things, (especially when you compare it to feed and wages), but we know every little bit helps when it comes to budgeting. So to help you out, we’ve done a bit of research and pulled together a few of our favourite ways to save energy on your farm. 1. Maximise off peak rates - use as much power as possible during off peak hours to reduce your energy costs. Things like using the irrigators during off peak times, put in relays on your effluent pumps, and filling your water tanks at night. Meridian has seasonal summer rates which help when power usage is at its highest which has truly benefited some of their customers. Or talk to them about their relationship with Regen Water Service who can help reduce energy use through optimal irrigation. Using Regen to only use irrigation when required reduces the power bills substantially. 2. Water heating makes up about a quarter of your dairy shed electricity - you can reduce the cost to heat your water by: a. improving the efficiency of your existing electric water heating system by installing heat 1 2

recovery technology which can be used by your dairy shed hot water heating system, reducing the amount of electricity needed b. reducing your hot water use can ease your2 energy costs by $300 to $500 per year . Some ways to save hot water are: i. use only the required amount of hot water for each wash (some dairy sheds use significantly more hot water than others of similar size and could benefit from a careful review of washing practises) ii. eliminating losses from dripping taps or overflowing cylinders iii. add a time switch to the heater so it turns on just before you need it. Energy loss can be greatly reduced if the heating is delayed until nearer the time the hot water is required iv. existing cylinders and piping that are exposed to draughts will benefit from being enclosed or otherwise shielded from draughts. Install wraps to older cylinders and insulate all warm or hot pipework v. check your thermostat - any signs of steam discharging from the overflow pipe should be a signal to suspect a faulty thermostat

3. Cooling milk – there are not as many options available for cooling milk as there are for heating water however according to the Venture Southland research, you could consider: a. increasing the efficiency of the pre-cooling system – you could consider investing in the installation of a variable speed drive on the milk pump which adjust to the airflow requirements, enabling the pump to run at the desired speed rather than full speed the whole time. You may need to investigate the cost to implement compared with the savings over a period of time before implementing. b. ensuring that the milk vat refrigeration unit is operating at normal efficiency; and c. insulating the milk vat, and d. you could reduce your electricity cost (but not usage) by shifting cooling load to the night hours was also identified as a possibility. 4. Lighting – although lighting is not a major cost, it is one that can be easily reduced. If designing a new shed, make the most of natural light by using translucent sections in the build. Existing lighting costs can be reduced by minimising running hours (i.e. switching off when not needed) and choosing energy

CASH FARM WORKING EXPENSES table – DairyNZ Economic Survey 2015-16 Improving Dairy Shed Energy Efficiency, Venture Southland, 2007

Maximise off peak rates

Water heating

efficient light fittings (i.e. twin tube fluorescent fittings, replacing the 500W quartz halogen floodlights with 150W high pressure sodium (or metal halide) floodlights). Maintenance of light fittings is also important. Light output will deteriorate with time unless the fittings are regularly cleaned and lamps replaced. As with any machinery, maintenance is key. Ensure you get these regularly checked and serviced. If you haven’t already, check out the EECA Dairy Farm Energy Tool – by answering a few simple questions you can find out how your energy consumption compares to others and potential savings you could make along with a raft of other recommendations on how you could reduce your dairy farm energy. To make sure you are getting the most out of your electricity, including seasonal rates, get in touch with Meridian’s on-farm electricity experts for a free no obligation quote for your farm and your home. Visit meridian.co.nz/agri or call our dedicated team on 0800 496 444. The energy saving tips and recommendations made throughout the article are sourced from Venture Southland, Improving Dairy Shed Energy Efficiency, the EECA dairy farm energy efficiency tool and EECA Energywise.

Advertising feature

Cooling milk

Lighting

Meridian Energy, saving summer Join the Meridian customers making the most of our seasonal rates this summer, make sure you aren’t missing out. Saving is easy when you’re with the electricity provider who has partnered with your favourite rural supply company.

Simply call our dedicated agribusiness team on 0800 496 444 or visit meridian.co.nz/agri to find out more

*Terms and conditions apply, visit meridian.co.nz/tandc

12

Dairy Focus

Cost effective fuel solutions RD Petroleum (RDP) was established to provide a professional, competitive, service-driven distributor for fuel and oil products throughout the South Island. RDP provides fast, reliable fuel and support to rural, farm/agricultural and commercial customers. RDP operates tankers from bases in Nelson, West Coast, Christchurch, Timaru, Dunedin and Invercargill. RDP has a centralised dispatch and scheduling team based in the South Island, with a real time overview of the tanker fleet. Matched with an up-to-date database of client orders. RDP is able to provide the highest level of delivery service. This leading edge technology, ensures maximum utilisation of the fleet, allowing RDP to be one of the most cost effective fuel distributors in the business.

Bulk fuel services include • Farm deliveries • Commercial bulk deliveries i.e. contractors and transport companies • Commercial heating deliveries

www.guardianonline.co.nz

ENERGY FEATURE

PHOTO SUPPLIED

Lyndon Knight, territory manager, Mid and South Canterbury.

• Home heating deliveries With six territory managers around the South Island, RDP can also provide expert advice on environmental compliance, Worksafe adherence and the purchasing and installation of on-farm storage options. We are a local supplier of community service stations. We have a very dedicated team working in the RDP’s operations office in Christchurch. This is where all dispatching is undertaken as well as accounts and administration. We are constantly adapting and making use of new technologies and because of this we are able to offer our customers a delivery service second to none. Advertising feature

Profit vs environment Can we protect and improve our environment; and increase our profits? Often this is a balancing act, with costs and benefits both hard to accurately quantify. However, with solar we’ve got a win / win! PV solar provides a sustainable and eco-friendly way of reducing power costs; giving after-tax returns of over 20 per cent in some cases, starting from year one. With some panels offering a 30 year performance warranty – this return not only keeps on giving, will probably increase over time. So, are there environmental benefits when most of our electricity is “green” hydro power? On first look “no”. However, it is surely just a matter of time before power demand necessitates more hydro stations. That means we need to dam (many would say damn) more rivers. The more solar power we can all produce, the smaller the need to create more hydro power stations, resulting in less environmental impact. Our combination of good sunshine hours and increasing power costs provide a compelling argument to “Go Solar”.

Many of those who investigated solar have decided there’s no point in waiting – the returns are there now and they’re already reaping the financial rewards. So, are you missing out? Get an expert solar assessor to meet with you so you can make an informed decision and get some independent figures on what a solar system should produce at your site. Even if your power use is outside the peak solar times there are many options that allow you to save power for later use including new battery options. For free advice, or information contact Green Spark Solar 0800 2467 6527 or text 021 038 6107. Advertising feature

Is it wrong to make money from the sun?

Green Spark Solar

Imagine making money every day the sun comes out! (without working). Yes, every day! Solar Electricity lets you do just that – light from the Sun converted into free power, so you buy less from the grid. Green Spark Solar provides a wide range of solar options that can give you a fantastic tax-free return on investment! Help protect against the rising cost of power and benefit the environment. PRODUCE YOUR OWN POWER BEFORE CHRISTMAS. CALL NOW! Free Assessment 0800 2 GO SOLAR (0800 2467 6527) Ask about our dual glass panels with 30yr warranty!

SOLAR

POWER

YOUR FARM

UP TO

% 0 2

N O N R U RET ST M E N T INVE

5

AS LOW AS

YEAR PAYBACK

Farm solar specialists FREE onsite consultation Proposals specific to your site Accurate information to make decisions 25 year warranties, 40+ year life expectancy Unrivalled solar/electrical technical knowledge Committed after sales service

Contact us now, while the sun is shining!

0800 SUNERGY sunergysolar.co.nz

Buy or Lease

14

Dairy Focus

www.guardianonline.co.nz

Walking the talk Recent dealings with Clients have indicated an alarming increase in animal health problems which cannot be treated. We have always had that annoying group of cows with somatic cell counts higher than the rest of the herd which we are forced to cull to keep our bulk scc at a manageable level. Now we find that certain strains of mastitis are, upon detection directed down the same path. This latest scare with micoplasma bovis contained in one farming group in the Oamaru area and the subsequent resulting management of it by murdering cows casts a very dark cloud over the direction we may be heading. I have seen some amazing data and collected information during my self education as a biological consultant and upon reading my website you will see my point of view can be interestingly unique. My thought process and data collection on this micoplasma bovis is also way left field but nevertheless I am urged to share it with you.

David Law

Please take into consideration that I am sharing my theory, based on my biological background and observations. 1. This outbreak is confined to one farming enterprise following a certain management system. 2. In areas of the world where micoplasma bovis is more prevalent, farmers follow similar farming systems. 3. Is this disease a result of a farming system rather than a contagious disease? 4. What are the factors that may lead to the symptoms which are appearing with these micoplasma bovis victims. There are some big picture information which I believe may be indirectly connected

chlorine kill aerobic Bacteria 6. Good biology beneficial to animal health is generally associated with aerobic bacteria. 7. Bad and pathogenic disease causing biology is generally associated with anaerobic bacteria 8. Effluent, good or bad, is spread on pasture 9. This feed, whether directly or after harvesting, is fed to cattle. 10. Chlostridia, botulism and micoplasma bovis are all anaerobic bacteria. 11. Chlostridia is generally present when anaerobic effluent is present in feed. 12. A symptom of cattle with chlostridia is the inability for the animal to suck water in the normal way. They lick at it instead. 13. Nutrients from the rumen need water to transport around the body past the rumen. 14. With the inability to physically drink adequate water, the animal effectively starves after the rumen.

15. The animal is unable to fight disease with no immunity. 16. Micoplasma bovis, which is always present takes advantage and becomes prevalent. 17. Micoplasma bovis is generally present and associated with botulism and chlostridia. 18. Testing for chlostridia and Botulism will, if present, confirm the origin of the micoplasma bovis. If this information checks out then we can treat the disease, manage it and prevent it in the future. My vet colleague in Denmark stated that, after the death of hundreds of cows in Germany, anaerobic effluent is not irrigated to pasture anymore. Of course, MPI have already made their decision and they seem to think differently! Killing cows will definitely fix the symptom! David Law owns Forward Farming Biological Consultancy Visit for more ; www.forwardfarming.co.nz

Need ultra-Fast Rural Broadband?

WALKING THE TALK

to the initial cause of this disease. My own experience connected to other biological scientists, and specialist vets specifically working on this disease in Europe have led to this connection. The following are a list of basic observations I have collected: 1. Dairy farm effluent is generally either anaerobic or aerobic 2. Symptoms of anaerobic ponds are crusted and have an effluent pH below 7. The thicker the crust, the lower the pH. 3. Symptoms of an aerobic pond show lesser crust with a pH of the effluent above 7. The higher the pH over 7 the clearer the pond is of crust and sludge. 4. Both these bacteria types have exclusive competition, so as the conditions change further away from pH 7, either way, the bacteria which enjoy those conditions dominate. 5. Chemicals used in dairy farm cleaning, particularly

HOUSE | SHED | FARM

Phone

Surveillance

Wi-Fi

TV on demand

Request a FREE site assessment

0800 000 945 www.ultimatebroadband.co.nz

HEAD SCRATCHER #1 Every year I’m given the same fert plan, which is the same as my neighbour’s fert plan, which is the same as the guy 20km down the road. That doesn’t make sense. Our soils can’t all be the same, year after year. There are two key issues here – the nature of soil and the nature of fertiliser systems.

Damaging the soil Grass needs N to grow. But excessive levels of N lowers the pH of the soil by stripping calcium. When low pH occurs, these unintended negative affects occur:

1. The nature of soil

Clover is shut down

Even though many farmers believe that to grow grass, you need to feed the grass, the truth is you actually need to feed the soil. That’s because soil is like the stomach of the grass – whatever nutrients the grass needs, it gets from the soil in which it is rooted, and from the trillions of microbes that live there.

Clover is a nitrogen fixer, locking in and releasing N as needed. Overuse of artificial N causes clover to shut down which allows the overshadowing of rye grass.

Nutrients are tied up

To be abundant and healthy for your animals, grass needs a combination of 12-16 nutrients. Among them are calcium, magnesium, nitrogen, potassium, sodium, phosphate, sulphur, zinc, boron, copper, manganese, iron, and selenium.

Up to 16 nutrients are needed in the soil to grow healthy grass and maintain good animal conditioning. When NPK fertilisers lower the soil pH below 6.0, a range of grass-growing nutrients become tied up, making them less available to the plants.

Some of these minerals directly impact plant growth. Others help plants by feeding the soil microbes that convert nutrients into forms that plants can easily uptake. Some minerals condition the soil and suppress plant diseases, while others promote root development. Here’s the important thing: it is the combination of these soil minerals in the right amounts that causes grass to grow in a nutrient-rich fashion. Too much of one nutrient ties up and reduces the effect of another. Too little of something allows other nutrients to be overly active to the detriment of grass growth and animal health. The right balance is crucial. Given the complex needs of your grass and the variables that affect the soil, why are many fert plans generic and mostly filled with NPK?

2. Fert plans are preoccupied with feeding grass Most fertiliser companies seek to grow grass by feeding the grass. This explains why their primary ingredients are nitrogen, phosphorus, and potassium.

Damaging the good grass-growing organisms

• Nitrogen promotes plant growth. It is part of every protein in the plant and is required for virtually every process.

Within 1m2 of soil live trillions of beneficial organisms: bacteria, fungi, protozoa, nematodes, anthropods, and earthworms. These soil organisms are absolutely indispensable. Here are some of the crucial things they do:

• Phosphorus is involved in the metabolic processes responsible for transferring energy from one point to another in the plant. It is critical in root development. • Potassium helps regulate plant metabolism and affects water pressure regulation inside and outside of plant cells.

Mineralise nutrients into plant-available forms Release excess nitrogen and nutrients for plants to use Increase nutrient retention Suppress disease-causing pathogens Detoxify the soil by degrading toxic materials Improve the accumulation of organic matter Produce plant-growth hormones Ensure root architecture is correct and extensive Enhance soil structure to improve water flow and reduce erosion

When it comes to feeding grass, Superphosphate and Urea are the go-to fertiliser products. That’s why farmers are given the same fert plan year after year, regardless of what their soil tests reveal.

What’s the problem with that? UREA contains high levels of nitrogen (46%) and SUPER is very acidic. When farmers use UREA and SUPER for prolonged periods, the unintended consequences are damage to the soil and the soil biology.

A low pH stunts the reproduction and activity of these soil micro-organisms.

What is Dolomite and how does it help farmer grow grass? Dolomite is a 59% calcium 39% magnesium carbonate occurring as a natural rock deposit found only at Mount Burnett, Golden Bay, New Zealand. Calcium and magnesium are two nutrients that link everything together to enable all the elements to function at full capacity. Here are some of the ways that Dolomite helps farmers: • Significant reduction in animal metabolic disorders • Improves mating performance • Improves worm and microbial activity • Increases nutrient storage and availability • Promotes more vigorous clover and plant growth

• • • • • •

Continually improvement of soil structures Leads to stronger roots which grow further down into the soil Reduces the reliance on nitrogen inputs Reduces or eliminates the need for pasture dusting of MgO Promotes healthier disease-resistant and pest-resistant crops Consistently lowers fertiliser input costs

Comprehensive SOIL TEST: Call 03 525 9843 or email sales@goldenbaydolomite.co.nz

16

Dairy Focus

www.guardianonline.co.nz

ANIMAL HEALTH FEATURE

Be diligent around mating time Around mating time lameness seems to increase. Most people believe that the reason for this is the extra pressure that is on the hooves when a cow is being bulled by another cow. This goes alongside the theory that hooves get damaged by pushing, twisting and turning. Even many non-agricultural based people assume that to be true. When I explain my job to them they always seem to ask if the problem is because of the long walks. So, it is not surprising that the extra weight on the hooves is seen as the cause of the increased lameness around mating time. The problem is that, as far as I am aware, mating is a normal, natural phenomenon. If cows go lame because of the extra pressure, why do we not see more lameness with animals in the wild? Is it because we are breeding cows that have weak hooves? If that was true then this would have occurred in the past 40 years or so because lameness was not a big deal back then - even though cows

Fred Hoekstra

VEEHOF DAIRY SERVICES

did go through mating periods and they were twisting and turning on concrete. So, if it is the breeding that is to blame, how much longer do you think we will be milking cows for, as hooves seem to deteriorate at a rapid pace? Another question that is hard to answer in this theory is why do we see most of the problems in the back feet and not so much in the front feet? Front feet carry 60 per cent of the weight of a cow so, if the hooves are genetically weakened, the front feet should suffer more than the back feet. What I am saying is that it is not likely that lameness is caused by external trauma. It just doesn’t make sense and, as

there is no evidence to back up that theory, one must consider that there are alternative explanations. In all my experience the most obvious problem is unhealthy live tissue in the hoof. If the live tissue (corium) is unhealthy it cannot produce a good quality hoof and likewise, if the corium is healthy it must produce a good quality hoof. So, what makes the corium unhealthy? It is an unbalanced diet and prolonged stress. Stress encompasses a lot. It is not just poor animal handling but also heat stress, lack of resting time, lack of good quality water and so on, and when it comes to mating time you will find that cows are generally spending more time waiting than normal. Milking may take a bit longer and bulling cows go back in the holding pen after being milked. It is already nearly impossible to provide enough resting time for our cows on a pasture-based milking system. Cutting back on resting time in the mating period will

only exacerbate the problem and lameness is a result. Farmers who use heat detection cameras on the platform are at more risk. This technology is not yet accurate enough and it pulls more cows out of the herd than there are bulling cows. This means that a number of cows are

going back in the holding yard waiting for nothing. My advice is to be even more diligent around mating time with providing as much paddock time as possible. I am always interested in receiving your thoughts and feedback if you want to email me on fred@veehof.co.nz.

Breeding Bulls • Yearling Jersey Bulls 290kg+ : $450 lease • 2yr Jersey Bulls: $450 lease, from $1600 purchase • 2yr Friesian Bulls: from $1700 purchase • Beef Bulls: from $2000 purchase * GST exclusive

All bulls have been blood tested & vaccinated for BVD Available from Southland to North Canterbury.

Lines of in milk cows starting to come available. Call today to discuss your option for breeding bulls this season.

Contact Paul Bailey

M: 027 229 9774 E: paul@canterburylivestock.co.nz

ANIMAL HEALTH FEATURE

17

SCANNING WITH HONESTY, INTEGRITY & EXPERIENCE

Leaders in pregnancy scanning YOUR LOCAL COW

Benefits of scanning with Ultra-Scan • Scanning is the main focus of Ultra-Scan • Ultra-Scan technicians are scanning specialists, scanning in excess of 600,000 cows per season • No hidden cost (no travel charged) • Reports delivered within 24 hours

SCANNING SPECIALISTS Ultra-Scan Ashburton Daniel & Nicole Jackson Ph: 0800 CANSCAN

Mobile: 027 226 2006

• Relatively stress free process for the animals • Local people with local knowledge

Ultra-Scan was first established in 1994 when the company developed a system using ultrasonic equipment to pregnancy test cows. The system they established is now a proven concept in the dairy industry and is still the preferred system of pregnancy scanning today. Ultra-Scan has grown to a nationwide network of 20 owneroperator franchisees. Ultra-Scan technicians are scanning specialists who are trained using our in-house systems developed over the past 20plus years. Continued research and development has enabled Ultra-Scan to maintain a solid and well-respected reputation in the dairy industry. Ultra-Scan’s team of local qualified and professional franchisees pride themselves on delivering superior farm services. Daniel and Nicole Jackson at Ultra-Scan Ashburton cover the Mid Canterbury region and have been Ultra-Scan franchisees for five years. And Scooter and Claire Palmer, who have over 15 years of dairy industry experience between them, deliver Ultra-Scan services to North Canterbury. They are part of the community and you will see them supporting local sporting teams, school events or

out canvassing for the IHC Calf and Rural Scheme. As an industry leader, UltraScan scans in excess of 600,000 cows per season and takes pride in our franchisees being experts in pregnancy diagnosis, and in delivering an accurate and efficient service. Our experienced and dedicated team focus on providing critical information, enabling farmers to make accurate and profitable management decisions. Ultra-Scan systems are robust, trusted, and have been tried and proven over a number of years. Our system is efficient in both herringbone and rotary sheds, with an experienced technician capable of scanning approximately 200 cows per hour. For larger herds two scanners is an option that farmers can choose to maintain efficiency. Scan results can be provided to the farmer in either calving order or tag order by email in PDF format, and can be electronically submitted to LIC MINDA or Ambreed for updating of farm records if required. Scan results are available the same day as the scan is completed. Call today and book in early for your six week in-calf scan. Advertising feature

Ultra-Scan North Canterbury Scooter & Claire Palmer Scooter: 027 360 1162 Claire: 027 360 1269

Accurate dating of the foetus between 35-90 days after conception LIC MINDA & Ambreed Insights records updated Same day electronic results of scan provided in calving date and tag number order

TESTIMONIAL

No mileage or farm visit fee charged

“I’m using Ultra-Scan on my farm again this season. They are easy to deal with before the job, the scanning was fast, and the calving dates were accurate. They know their way around MINDA PRO and made sure the results were turned into useful information. Getting the reports the day after scanning meant no delays in choosing culls. And, I like knowing it’s going to be the same people doing the whole operation, no surprises. Definitely value for money.”

- Paul Stewart, Dorie dairy farmer

Certified Specialist Technicians – Our primary focus is SCANNING www.Ultra-Scan.co.nz f

g+

in

CALL TO BOOK YOUR SCAN IN TODAY!

Dairy Focus

18

www.guardianonline.co.nz

ANIMAL HEALTH FEATURE

MPI backs antibiotic awareness week The Ministry for Primary Industries (MPI) last week publically supported the theme of this year’s World Antibiotic Awareness Week: “Seek advice from a qualified health care professional before taking antibiotics”. That advice applies to treating livestock with antibiotics just as much as it does people. Research shows that the global growth of antimicrobial resistance is undermining the effectiveness of antibiotics. “Antibiotics are important for treating bacterial infections in humans and animals but we need to make sure they are used appropriately,” MPI’s director systems audit, assurance and monitoring, Allan Kinsella, said. “Animals sometimes need antibiotics to treat bacterial infections. All antibiotics registered for use in animals in New Zealand are rigorously assessed before being used,” Kinsella said. Most antibiotics can only be used to treat individual animals or groups of animals

that show symptoms of disease or prevent sickness in cases where there’s a high risk to the animal. “New Zealand is a low user of antibiotics in food producing animals compared to many other countries,” Kinsella said. “However, we need to remain vigilant. Any animal owner who thinks their animal should be treated with antibiotics should discuss this with their vet.” This year New Zealand began implementing its fiveyear Antimicrobial Resistance Action Plan to minimise the impact of antimicrobial resistance to human, animal and plant health. The plan’s activities cover five different areas: awareness and understanding; surveillance and research; infection prevention and control; antimicrobial stewardship; and governance, collaboration and investment. MPI is working with the Ministry of Health as well as a wide range of groups and organisations to make sure we are on the right track.

®

BOSS® is a registered trademark of Alleva Animal Health Limited. BOSS® Pour-on is approved under the ACVM Act 1997, No. A10817. Complimentary ham only available while stocks last. Complimentary ham received may vary from the advertised image. Qualifying purchases: Purchase 1 x 2.5L of BOSS pour-on and receive 1 free ham. Purchased 1 x 5L of BOSS pour-on and receive 2 free hams.

PURCHASE

BONUS.

Kinsella said that New Zealand has a robust regulatory framework for managing antibiotics and other veterinary medicines.

PURCHASE

NOW THIS IS A CHRISTMAS

This five-year plan builds on previous work MPI has undertaken to manage antimicrobial resistance in animals.

1 x 2.5L

1 x5L

GET

GET

www.alleva.co.nz

The Ashburton App is the one-stop shop for everything the Ashburton District has to offer.

Ashburton App

THE

“MPI must be satisfied that all antibiotics approved for use in animals are appropriate to the animal and do not harm human health.”

Download FREE today and keep up-to-date with: • Rural & Ag • Rural News • Weather

DOWNLOAD

NOW!

ANIMAL HEALTH FEATURE

19

Stock movement vigilance crucial Knowing the movement history of any dairy animal coming on to your farm is crucial to keeping bovine tuberculosis on the path towards eradication. “Being smart about where stock is coming from is important,” says the TBfree programme’s disease management leader Kevin Crews. “Any purchasing or grazing of stock carries a risk of spreading TB, so vigilance is imperative.” In Mid Canterbury the wildlife population is deemed TBfree, meaning that any TB risk to herds in the area would come from stock movement, so asking the correct questions prior to any movement helps protect farmers and their businesses. NAIT registration and NAIT movement recording is also critically important for TB risk mitigation. It is also a legal requirement under the NAIT Act, which farmers need to be constantly aware of. Ensuring the stock agent or vendor is asked where the animals have been

and if they have had a recent TB test helps farmers assess the risk and make the correct decisions for their herds. Farmers can protect their herds from movement-based infection risk by being careful to discuss the TB testing history of any incoming stock with their owner, and by ensuring Animal Status Declarations are current and correctly completed. The ASD records not just the most recent TB test, but whether a herd is located in a movement control area, and the TB status of any animals that have been introduced into the herd. “These are some of the key questions to review before making any decisions,” says Dr Crews. “Farmers are in the front line of TB eradication and key to achieving the TB Plan’s goal of eradicating TB from livestock by 2026,” says Dr Crews. More information on the ASD and stock movements is available at ospri.co.nz. Advertising feature

WE OWE IT TO FUTURE GENERATIONS TO GIVE THEM A COUNTRY THAT’S TB FREE

BE TB SMART Three simple steps for protecting your livelihood

Farmers are in the front line of TB eradication, says OSPRI disease PHOTO SUPPLIED management leader Kevin Crews.

1. TEST YOUR ANIMALS

2. UPDATE ASD FORMS

3. PURCHASE WISELY

TBfree is an OSPRI programme

ospri.co.nz

John Deere 6820 Premium

John Deere 7530

Case IH MX100C

$46,000 + GST

$78,000 + GST

$29,000 + GST

6274 Hrs

Case IH MXU115 5776Hrs

$35,000+GST

6183hrs

Case IH MXU115 4533Hrs

$59,000+GST

6495 Hrs

Case IH CVX1135

Case IH MXU115X

Case IH MXM175 FHPTO

Case IH Puma 145 CVT

Case IH Maxxum 115 MC

$34,000 + GST

9391 Hrs

7005 Hrs

$38,000 + GST

$66,000 + GST

New Holland T7.170

Case IH Puma 210

Case IH Magnum 310 CVT

New Holland T7040

$97,000 + GST

$240,000 +GST

$64,500 + GST

Shibaura 6340

McCormick XTX 145

Iseki SX75

Case IH 6088

$49,000+GST

$9,000+GST

$POA

3625Hrs

$11,000 + GST

Case IH 2188

$120,000+GST

895 Hrs, New Warranty

2733Hrs

Case IH 8010 Axial Flow $250,000 + GST

6113 Hrs

5751Hrs

Case IH LBX432 Rotor Cut

$45,000 + GST

$71,000 + GST

1500 Mill Hrs 24ft Vario Front

$35,000+GST

3951 Hrs

$68,000 + GST

New Holland TL100A 7360Hrs

$35,000+GST

Case IH 1680 Axial Flow $65,00 + GST

Claas Quadrant 3400

Case IH 8575 3’ x 3’

$POA

$19,000 + GST

Giltrap Slurry Spreader

Kuhn VB 2190 Round Baler

McHale 998 Bale Wrapper

Robertson Little Ripper Bale Feeder

Bogballe L2 Pluss

$29,500 + GST

$45,000 + GST

$35,000+GST

$16,000+GST

$9,500+GST

Pottinger 1252 C S

Alpego RH300 Power Harrow

McIntosh CP900SF

Goweil G3020Q

Amazone Cirrus 4001

Line Four Rotor Rake

Rear packer roller, very tidy

$22,000 + GST

$25,000 + GST

$40,000 + GST

12,000Ltrs

$49,000 + GST

11200 bales

$23,000 + GST

Silage Wagon

New

Profi Bale Wrapper

For more information, or to view any of our tractors, contact: Ashburton 03 307 8027 Amberley 03 314 9055 Leeston 03 324 3791 Timaru 03 688 2179 www.cochranes.net.nz

Super 4 mtr Drill c/w Rear Rollers

www.guardianonline.co.nz

21

Get an international perspective There are huge opportunities out there for the New Zealand agricultural industry. Why not sneak in under the radar and see what is out there for your dairy operation. Connecting with international farming colleagues, exchanging ideas and looking at your markets can give you a much wider perspective on the global dairy industry and where it’s heading. Whether it’s taking a look at Northern Hemisphere housed cow operations or hi-tech robotic dairy systems; dual purpose beef/dairy systems; effluent management and conversion to biogas; or seeing how pastoral grazing systems are working in places like South America - there’s a lot to see and learn out there. It was interesting, for example, on a recent group tour to Europe to compare New Zealand’s large scale farming with that of a small farm country like Austria. Initially we wondered how farmers were supposed to survive on farms with only a few hectares, often less than

Ku Cafe adding value in Austria .

20ha. Having been there, there are two obvious answers: one is they add value to their farm products; the other, they receive EU subsidies. An excellent example was a cow café where around 70 Simmental/Fleckvieh cows were robotically milked and seemingly living a very comfortable life in well-lit, clean and warm stables. The farmer built a café into

beyond commodity production and seek innovation from elsewhere - considering ways to challenge the status quo. The above visit also brings up the point about agricultural subsidies. No doubt they, like many other European farmers, received generous subsidies for capital expenditure associated with getting these types of projects up to speed. Circumstances are quite

different in New Zealand and most New Zealand farmers prefer the free trade environment in which we work. However, we need to differentiate and add value to iconic Kiwi products so we also sustain a vibrant agricultural economy. We’re here but many good ideas are discovered elsewhere. Why travel with Farm To Farm? We have specialised in agricultural tours for farmers for over 30 years. It is what we do. We customise our tours to meet your needs and we have excellent colleagues and networks in over 35 countries. Contact us info@farmtofarm.co.nz or phone 0800 3838 747 to discuss your options. Advertising feature

SPAIN & PORTUGAL

SOUTH AMERICA

UK & IRELAND

ITALY, SWITZERLAND & FRANCE

AFRICA FARMING & SAFARI

JAPAN / VIETNAM

CANADA & ALASKA

AUSTRALIAN TOURS

SCANDINAVIA

May 2018

May/June 2018

May/June 2018

June/July 2018

Rural Co. Ad 11/2017 194 x 138mm

the complex overlooking the herd and all the action. They served coffee, apple strudel and other dairy friendly delicacies. The farmer said it gave them a whole new income stream from hosting hundreds of visitors and school groups wanting to see what dairy farming was all about! Although conditions differ around the world, New Zealand dairying can look

PHOTO SUPPLIED

May/June 2018

June/July 2018

June/Sept/Nov 2018

May 2018

July 2018

Unique travel experiences for farmers!

Connect with overseas farmers and producers, exchange ideas and enjoy wonderful experiences, hospitality and cuisine throughout the world. Travel, learn and discover with Farm To Farm Tours - New Zealand’s most experienced agricultural tour operator!

For full tour details and itineraries visit:

w w w. f a r m t o f a r m . c o . n z

info@farmtofarm.co.nz phone 0800 3838 747 92 Victoria St, Rangiora

22

Dairy Focus

EFFICIENT SYSTEMS FEATURE

www.guardianonline.co.nz

Helping to improve irrigation IrrigationNZ will be back on farms this summer, testing irrigation systems and helping farmers improve the efficiency of their irrigation. Last summer, in partnership with Environment Canterbury, we developed a new testing programme that saw 131 Ashburton farms with irrigation have their systems tested to see how they were performing. Farmers and farm staff were also interviewed to find out how they manage their irrigation systems. Over the next three months, we will be testing irrigation on around 100 farms in the Selwyn district. We’ll look at how farmers are operating irrigation equipment, whether water is applied evenly, how irrigation is scheduled and the maintenance carried out on equipment, as well as the monitoring of soil moisture and run-off. Thanks to the support of partner organisations Environment Canterbury, DairyNZ, the Foundation for Arable Research, Beef + Lamb New Zealand, Horticulture New Zealand,

Andrew Curtis

WATER WORKS

Synlait, Fonterra, Ballance Agri-Nutrients and Central Plains Water, the testing and evaluation can be carried out at a subsidised rate. Once the testing has been completed, farmers receive their results and have the opportunity to attend a dropin session. This provides them with a complete picture of how well their irrigation system is operating and also how they are managing it. Farmers are offered advice on what they can do to improve their irrigation performance. The testing programme carried out in Ashburton over the summer of 2016/17 was the first large-scale independent irrigation efficiency trial completed in New Zealand and identified

some important results, which are applicable to irrigators throughout New Zealand. New Zealand is actually a world leader in irrigation best practice, innovation and training and most farmers were actively working to ensure they were using water efficiently and using

technology to support the decisions they made. For example, 70 per cent of the farmers were using soil moisture monitoring technology. And just over half of all irrigation equipment showed good to excellent uniformity of water distribution, with 32 per

cent of systems having fair uniformity and only 16 per cent poor. The testing in Ashburton was carried out on dairy, sheep and beef, arable and deer farms and covered a range of irrigation equipment - centre pivots, laterals, travelling irrigators, hard hose guns and

www.guardianonline.co.nz

EFFICIENT SYSTEMS FEATURE

management Last summer IrrigationNZ tested irrigation systems and management on more then 100 Ashburton farms, this summer testing is being carried out in PHOTO SUPPLIED Selwyn.

sprayline systems. The test results highlighted that the performance of irrigation systems can deteriorate over time, however regular testing and maintenance of older systems helps to pick up and correct any faults. Worn parts in irrigators can contribute to less than optimal water distribution, with sediment in the

water supply, incorrect hardware or blocked nozzles being some other common factors affecting performance. The depth of water application is another important factor that impacts on crop and pasture growth. Factors that can limit application depth include incorrect set up and commissioning during installation, system constraints, poor maintenance and technology failures. Staff knowledge of how to use irrigation equipment, carry out soil moisture monitoring and irrigation performance testing are also key to achieving best practice in irrigation. IrrigationNZ offers a range of training courses – see www. irrigationnz.co.nz/events for details as well as our online resources to upskill farm staff. If you live in Selwyn and would like to be part of the upcoming irrigation efficiency project please visit www.irrigationnz.co.nz/events Andrew Curtis is chief executive officer of IrrigationNZ

23

Innovative app Dairy farmer turned inventor, Nigel Taylor, has launched an app that gives farmers a clearer view of what’s happening on the farm. JobDone, started as the winning idea pitched in the 2015 Fonterra Activate competition, now helps farm operators do everything from track timesheets to maintain equipment Instead of using a whiteboard or scrap paper to create a list of tasks, JobDone provides an easily accessible and real time view of what’s happening around the farm, as well as listing what tasks need to be done and monitoring progress and completion. Fonterra Farmer and Shareholders Councillor Greg McCracken uses JobDone on his property and says it has transformed his operations. “This is more than just an app, it’s an extra pair of eyes and ears,” said Greg. “Without a doubt, this system gives every staff member more focus on the jobs that they are doing, meaning the completion rate is way up. As soon as the worker checks their phone, they see what needs to be done - and you know how often people check their phones these days.” Not only does JobDone save farmers time and money, it makes operations

more efficient, improves health and safety compliance and helps the whole team contribute to solving problems. JobDone even takes the staff member through the steps involved in every task, ensuring all bases are covered. For example, when servicing a tractor, each item is listed and must be checked off, right down to the replacement of the sump plug. Greg said JobDone is a great example of the kind of innovative solutions that come from New Zealand farmers. Summing up the value of JobDone, McCracken says it has enabled his farm to become more organised, safer and better managed. “Once you use this system, there is no going back. It uses the smartphones we all have today, which makes it easy to get started. It’s just a better way to farm.” Farmers can find out more about JobDone and sign up for a one month trial by going to www.jobdone.nz Advertising feature

New milk cooling requirements are coming…

ARE YOU READY?

Are you Dairy Temperature Compliant? For all your dairy farming refrigeration needs, from standard refrigeration to complete cooling solutions.

MILK TO SILO AT 4oC

WE SUPPLY AND SERVICE THE PACKO ICE BUILDER

JobDone is a smart farming app that manages people, timesheets • • • •

Milk Silo Refrigeration Conventional refrigeration Water chilling Pre cooler design

• Hot water recovery • Boost systems • Electronics valves

health & safety and tasks. The whole team can use it on their computer or mobile and will

Phone 308 7182 | On Call 021 597 517 211D Alford Forest Road, Ashburton

www.stewartandholland.co.nz

become more organised, safer, productive and efficient. Find out more and sign up for a free trial at www.jobdone.nz

24

Dairy Focus

www.guardianonline.co.nz

EFFICIENT SYSTEMS FEATURE

More cost effective in the long run With new milk cooling regulations approaching the dairy industry many farmers are investigating options available to them to upgrade the milk chilling systems. Although there is a vast range of options available to farmers, it is a minefield for farmers to navigate through with all sorts of claims being made of systems performance, quality and efficiency, says Matt Cammock from Southfreeze Dairy. When looking at cooling options there are a few points to consider, the include capital cost, energy consumption and component quality. It’s fair to say the old saying of “you get what you pay for” hasn’t changed when it comes to milk cooling. Matt from Southfreeze believes the New Zealand made Varicool designed exclusively for New Zealand dairy farms should be at the top of the farmer’s list to consider. Although the capital cost of the Varicool units are often higher, they offer lower running costs which have been

verified by an ECCA Study. This makes Varicool’s cost of ownership much cheaper than a lot of competitor products. Varicool logs its energy usage and cooling and hot water output which is viewable to the farmer via his smart phone. Varicool has many points of difference, firstly it’s New Zealand designed using 3D-modelling software and manufactured in Hamilton. Farmers can visit the factory and see what goes into building a Varicool system. As suggested in the name, the Varicool uses variable speed technology and utilises a variable speed drive this is something most farmers will have experienced the benefit of in regards energy savings on their farm already when fitted on their vacuum pumps, water pumps and milk lift pumps. Varicool offers high grade heat recovery on all models as standard, along with remote support via a wide area network internet connection this gives the dealer, farmer and manufacture remote

access to the machine to save time and money on call-outs etc. which are often not due to the chiller unit itself. Issues with bore water cooling and plate coolers can often be identified remotely with information from the Varicool’s remote connection. Varicool can reduce the electrical load on a dairy shed compared with adding a dedicated pre-chiller unit to existing Dx Vat chillers. By making current and often ageing direct expansion vat chillers redundant, therefore utilising the power normally used by the direct expansion units not only to cool the vats but precool the milk to between 6°C and 8°C. This is all within “one box” which

takes up minimal space outside the shed. Another unique feature is the varicool’s ability to log the milk’s thermal gain due to the ambient air temperatures once it’s in the vat. Matt reports this back to the farmer once the unit has been running for a few months and can identify how much it is costing the farmer per day to keep the milk at holding temperature. Once this is established Matt can demonstrate how much benefit can be gained by using vat wraps. Varicool offers one of the most energy efficient systems on the market today to cool your milk on farm. Other services offered by

Southfreeze Dairy include ice bank systems as well as insulating tanks and vat wraps – something Matt says can also result in significant power savings. The company also offers preventative maintenance checks and emergency breakdown service. Matt says the company takes pride in offering a quick response and a first-time fix recognising the importance to farmers of having their plant up and running again as soon as possible. The company completes retrofits/upgrades of existing sheds or installs on new sheds and Matt urges farmers who have still not upgraded their milk cooling systems to meet the new regulations to take action sooner rather than later as he predicts pressure on the industry to supply and install if people leave things to the last minute. Based in West Melton, Southfreeze Dairy works as far north as Culverden and Parnassus and in the south to Hinds. Advertising feature

SNAP CHILLING | HEAT RECOVERY| |ENERGY ENERGYSAVING SAVING SNAP CHILLING | HEAT RECOVERY SNAP CHILLING | HEAT RECOVERY | ENERGY SAVING

EASY TO USE | HASSLE FREE | RELIABLE SNAP CHILLING | HEAT RECOVERY | ENERGY EASYSAVING TO USE | HASSLE FREE | RELIABLE

TO USE | HASSLE FREE |CHILLING RELIABLE |STANDARD MEETS CHILLING STANDARD | SAVES YOU MONEY MEETS | SAVES YOU MONEY EASY TO EASY USE | HASSLE FREE | RELIABLE CHILLING STANDARD | SAVES YOU MONEY MEETS CHILLING STANDARD | SAVESMEETS YOU MONEY

CHECK OUT THE NEW

CHECK OUTTHE THENEW NEW CHECK OUT CHECK OUT THE NEW

AIR CONDITIONING AND REFRIGERATION ENGINEERS DESIGN

INSTALLATION